Coke/sulfonated graphene carbon-graphite material for sealing piece and preparation method thereof

A technology for sulfonated graphene and seals, which is applied in the field of coke/sulfonated graphene carbon and graphite materials for seals and its preparation, and can solve the problems of insufficient ability to expand micro-cracks, reduced impact resistance, compression resistance, and flexural resistance Low-level problems, to achieve the effect of alleviating thermal stress and mechanical deformation, improving sealing failure, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

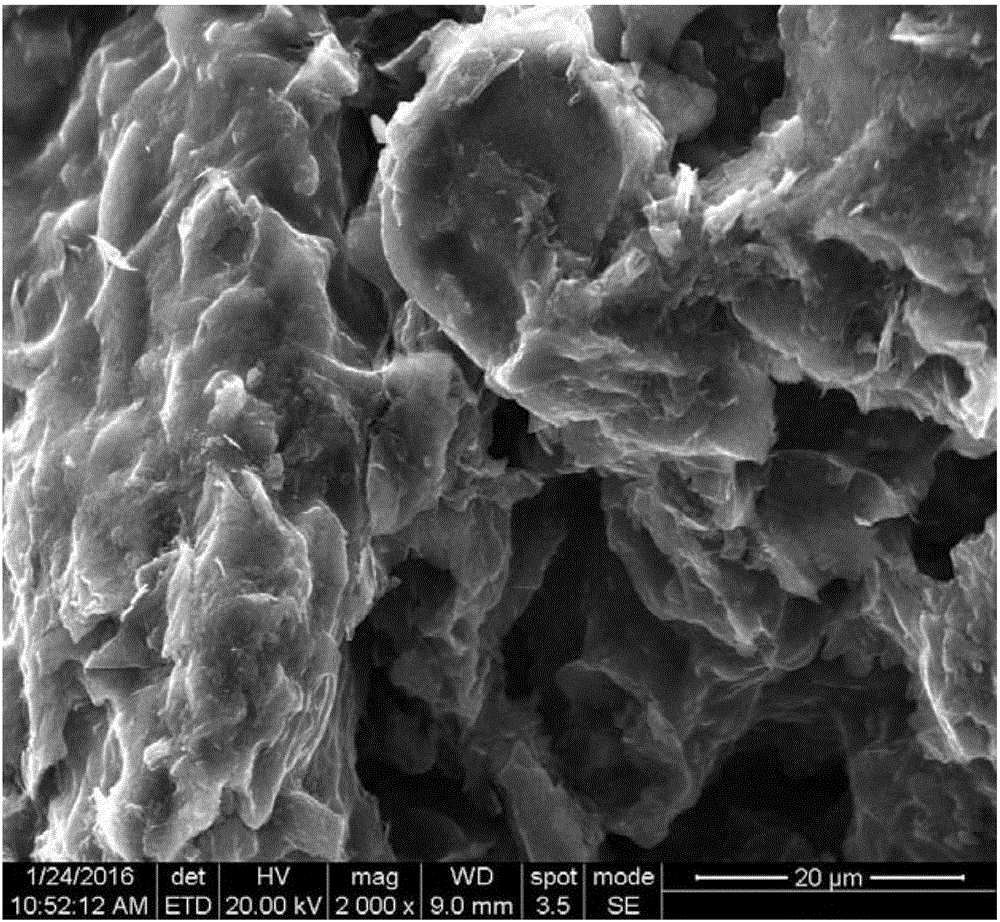

[0038] A coke / sulfonated graphene carbon graphite material for a seal, comprising the following raw materials in mass fractions: 22% coal tar pitch, 77% coke material and 1% additive; wherein: the additive is sulfonated graphene.

[0039] Sulfonated graphene is: the dispersion in water is >20%, and the sheet diameter can reach up to 100 microns.

[0040] Coal tar pitch is mixed with high-purity pitch and modified coal pitch at a mass ratio of 4:6.

[0041] High-purity asphalt is ultra-low quinoline insoluble high-purity coal tar pitch; ultra-low quinoline insoluble high-purity coal tar pitch physical and chemical indicators: softening point 85-90 ° C, ash ≤ 500ppm, coking value ≥ 48%, toluene insoluble ≥ 18%; quinoline insoluble matter ≤ 0.05%.

[0042] The modification of coal tar pitch is as follows: sulfonated graphene and anionic surfactant are maintained in distilled water at a temperature of 172°C, sheared at a speed of 5000r / min for 1h, dispersed, and then added to the...

Embodiment 2

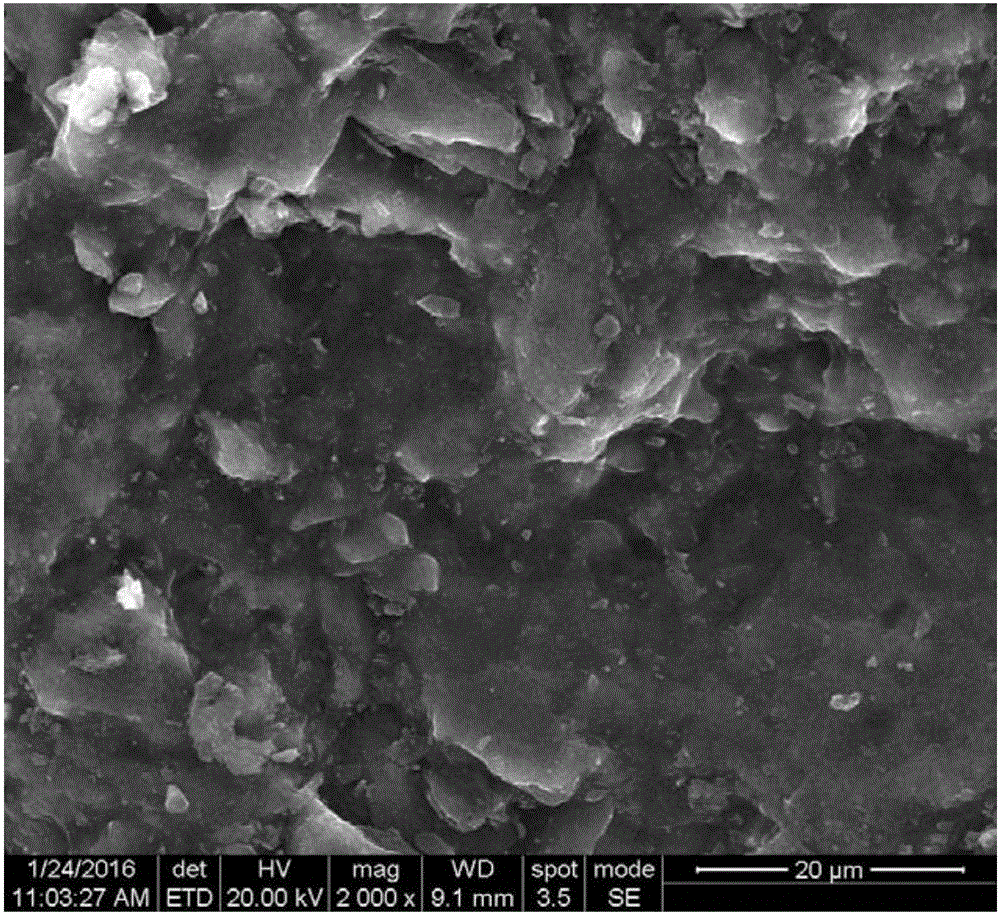

[0053] A coke / sulfonated graphene carbon graphite material for a seal, comprising the following raw materials in mass fraction: coal tar pitch 27.5%, coke material 72% and additive 0.5%; wherein: additive is sulfonated graphene and dispersant polystyrene A mixture of water-based resins, the mass ratio of sulfonated graphene to dispersant is 10:0.5.

[0054] Sulfonated graphene is: the dispersion in water is >20%, and the sheet diameter can reach up to 100 microns.

[0055] Coal tar pitch is mixed with high-purity pitch and modified coal pitch at a mass ratio of 5:5.

[0056] High-purity asphalt is ultra-low quinoline insoluble high-purity coal tar pitch; ultra-low quinoline insoluble high-purity coal tar pitch physical and chemical indicators: softening point 85-90 ° C, ash ≤ 500ppm, coking value ≥ 48%, toluene insoluble ≥ 18%; quinoline insoluble matter ≤ 0.05%.

[0057] The modification of coal tar pitch is as follows: sulfonated graphene and anionic surfactant are maintai...

Embodiment 3

[0068] A coke / sulfonated graphene carbon graphite material for a seal, comprising the following raw materials in mass fractions: 25% coal tar pitch, 74.5% coke material and 0.5% additive; wherein: the additive is sulfonated graphene and dispersant polystyrene A mixture of water-based resins; the mass ratio of sulfonated graphene to dispersant is 10:0.5.

[0069] Sulfonated graphene is: the dispersion in water is >20%, and the sheet diameter can reach up to 100 microns.

[0070] Coal tar pitch is mixed with high-purity pitch and modified coal pitch at a mass ratio of 6:4.

[0071] High-purity asphalt is ultra-low quinoline insoluble high-purity coal tar pitch; ultra-low quinoline insoluble high-purity coal tar pitch physical and chemical indicators: softening point 85-90 ° C, ash ≤ 500ppm, coking value ≥ 48%, toluene insoluble ≥ 18%; quinoline insoluble matter ≤ 0.05%.

[0072] The modified coal tar pitch is as follows: sulfonated graphene and anionic surfactant are maintaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com