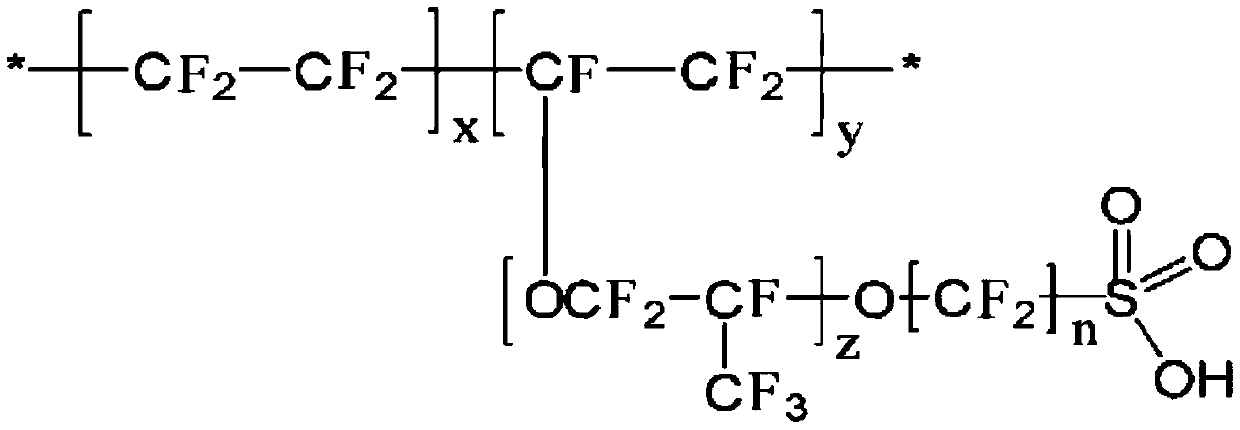

Preparation method of perfluorosulfonic acid composite ion conduction membrane

A technology of compound ion and perfluorosulfonic acid, applied in the field of ion exchange membrane, can solve the problems of complex membrane structure, and achieve the effect of improving ion selectivity, wide applicability and comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the preparation method of perfluorosulfonic acid composite ion-conducting membrane, the specific steps are as follows:

[0033] (1) Dissolve 6g of perfluorosulfonic acid resin (exchange capacity is 0.95mmol / g) in 100ml of dimethylacetamide solvent, heat and dissolve in a reaction kettle to form a perfluorosulfonic acid resin solution, and heat and dissolve under the temperature conditions 200°C;

[0034] (2) Dissolve 0.3g of perfluorocarboxylic acid resin (exchange capacity of 0.9mmol / g) in 30ml of dimethylacetamide solvent, heat and dissolve in a reaction kettle to form an additive solution, and heat and dissolve at a temperature of 200°C ;

[0035] (3) Add the solution prepared in step (2) to the resin solution prepared in step (1) for mixing, and stir for 24 hours to obtain a mixed solution.

[0036] (4) Pour the film-making solution prepared in step (3) onto a clean glass plate, and dry it to form a film under the conditions of a film-forming t...

Embodiment 2

[0039] In this embodiment, the preparation method of perfluorosulfonic acid composite ion-conducting membrane, the specific steps are as follows:

[0040] (1) Dissolve 6g of perfluorosulfonic acid resin (exchange capacity is 0.95mmol / g) in 100ml of dimethylacetamide solvent, heat and dissolve in a reaction kettle to form a perfluorosulfonic acid resin solution, and heat and dissolve under the temperature conditions 200°C;

[0041] (2) Dissolve 0.3g of perfluorosulfonic acid resin (exchange capacity is 0.83mmol / g) in 30ml of dimethylacetamide solvent, heat and dissolve in a reaction kettle to form an additive solution, and the temperature for heating and dissolving is 200°C ;

[0042] (3) Add the solution prepared in step (2) to the resin solution prepared in step (1) for mixing, and stir for 24 hours to obtain a mixed solution.

[0043] (4) Pour the film-making solution prepared in step (3) onto a clean glass plate, and dry it to form a film under the conditions of a film-fo...

Embodiment 3

[0046] In this embodiment, the preparation method of perfluorosulfonic acid composite ion-conducting membrane, the specific steps are as follows:

[0047] (1) Dissolve 6g of perfluorosulfonic acid resin (exchange capacity is 0.95mmol / g) in 100ml of dimethylacetamide solvent, heat and dissolve in a reaction kettle to form a perfluorosulfonic acid resin solution, and heat and dissolve under the temperature conditions 200°C;

[0048] (2) Dissolve 0.3g of perfluorosulfonic acid resin (exchange capacity is 0.83mmol / g) in 30ml of dimethylacetamide solvent, heat and dissolve in a reaction kettle to form an additive solution, and the temperature for heating and dissolving is 200°C ;

[0049] (3) Add the solution prepared in step (2) to the resin solution prepared in step (1) for mixing, and stir for 24 hours to obtain a mixed solution.

[0050] (4) Weighing 0.5 g of amino acid and adding it to the mixed solution prepared in step (3) for stirring, and stirring for 24 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com