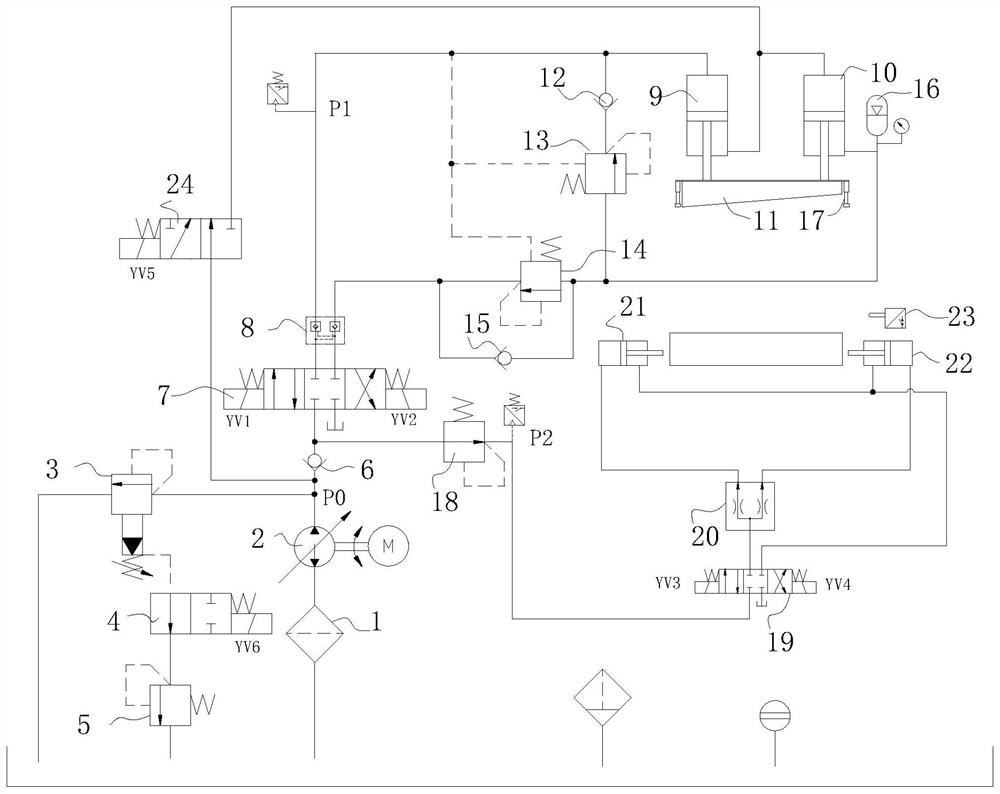

A hydraulic automatic control system of a hydraulic shearing machine tool

An automatic control system, hydraulic technology, applied in the direction of fluid pressure actuation system components, accessories of shearing machines, shearing devices, etc., can solve problems such as out-of-synchronization of tool holders, out-of-synchronization of left and right, and severe vibration of machine tools, so as to avoid The effect of changing the shearing angle, prolonging the service life and avoiding violent vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] As a specific embodiment of the present invention, the control oil port of the pilot relief valve 3 communicates with the oil tank through the two-position two-way reversing valve 4 and the direct-acting relief valve 5 in sequence, and the two-position two-way reversing valve The directional valve 4 is normally closed, and the set pressure of the pilot relief valve 3 is greater than the set pressure of the direct-acting relief valve 5; it also includes a contact switch 23 matched with the two-position two-way reversing valve 4, and the The contact switch 23 sends a signal when it detects that the cutter 11 is in contact with the object to be cut and makes the two-position two-way reversing valve 4 de-energized; The reversing valve 4 is normally closed. At this time, the system pressure is the smaller set pressure of the direct-acting relief valve 5, which facilitates the rapid downward movement of the cutter 11 at low pressure; when the cutter 11 touches the object to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com