Vacuum pumping welding device and method for pressure vessel

A technology for pressure vessels and welding devices, which is applied in the field of pressure vessel vacuum welding devices, can solve the problems of pressure vessels losing heat preservation effect, destroying the vacuum environment, and high processing costs, and achieves good sealing and welding effects, simple welding process, and stable welds sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

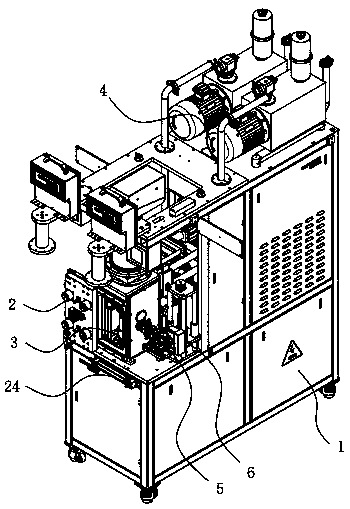

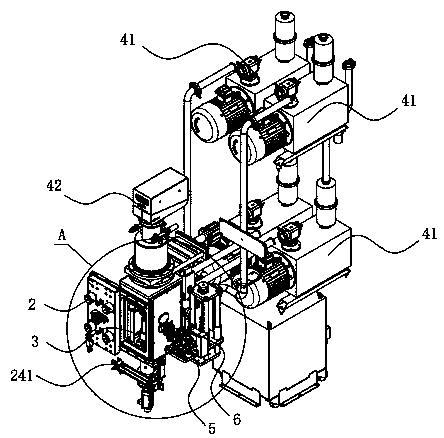

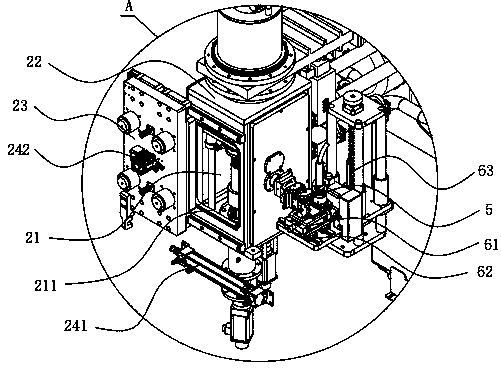

[0038] See attached figure 1 to attach Figure 5 As shown, a pressure vessel vacuum welding device includes a frame 1, a placement cabin 2 with a placement cavity 21 arranged on the frame 1, a pressure vessel fixture 3 located in the placement cavity 21, and communicated with the placement cavity 21. A vacuum mechanism 4, a laser welding machine 5 arranged on the frame 1 for sealing the pressure vessel 7.

[0039]Placement cabin 2 comprises the cabin body 22 that has placement cavity 21, and placement cavity 21 has the opening 211 that communicates with the outside, and the opening 211 of placement cavity 21 is positioned at cabin body 22 side, top surface or bottom surface, and placement cabin 2 also comprises cavity opening. The hatch 23 matched with 211 is used to seal and compress the hatch 23 to the sealing dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com