Method of cutting and detaching supporting beam for retaining and protection of foundation pit by means of rope saw

A technology for supporting foundation pits and supporting beams, which is used in excavation, infrastructure engineering, stone processing tools, etc., can solve the problems of difficult recycling of cooling water, serious waste of water resources, loss of cooling water, etc., and improve cutting efficiency. , not easy to run off, prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

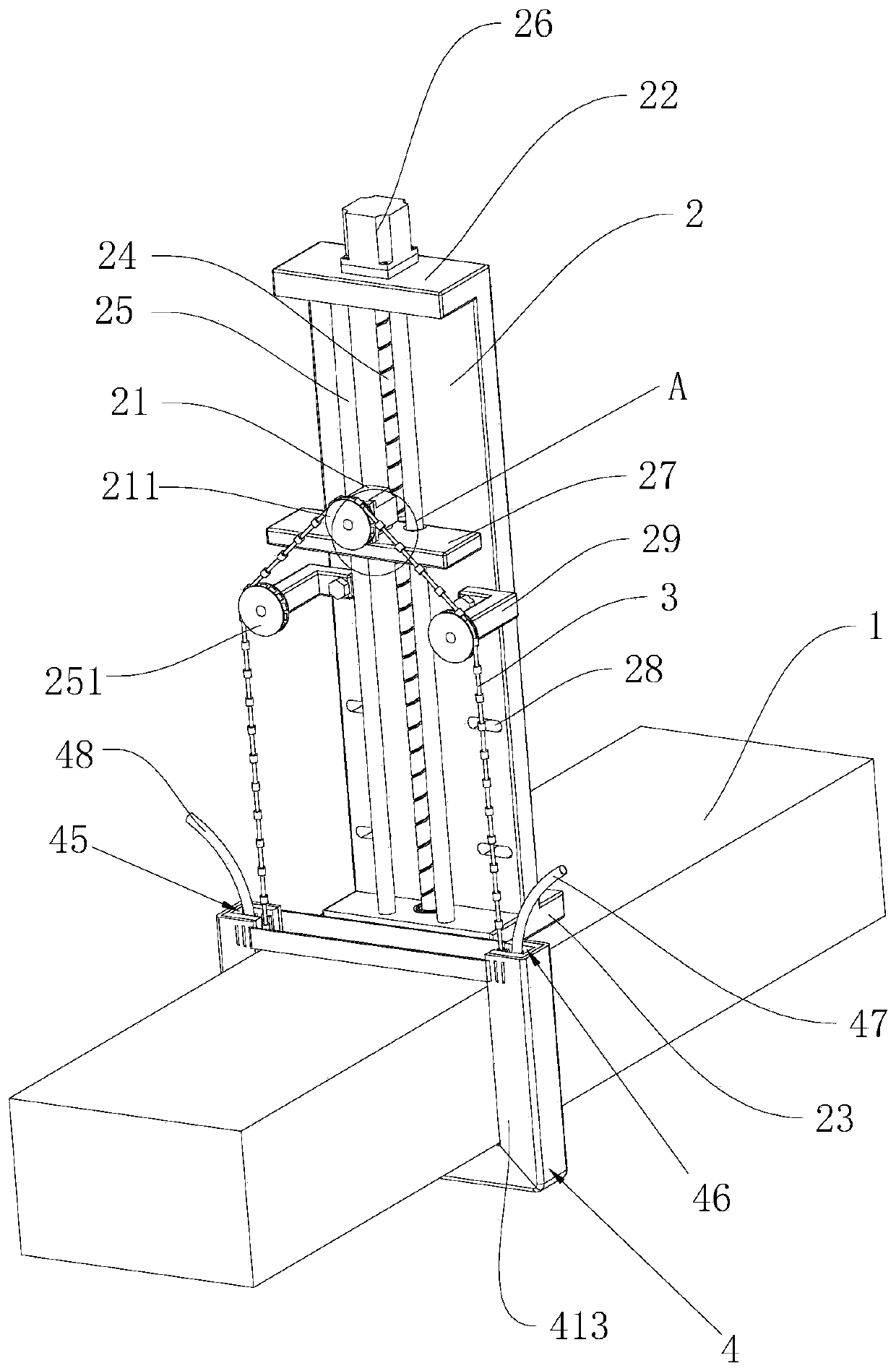

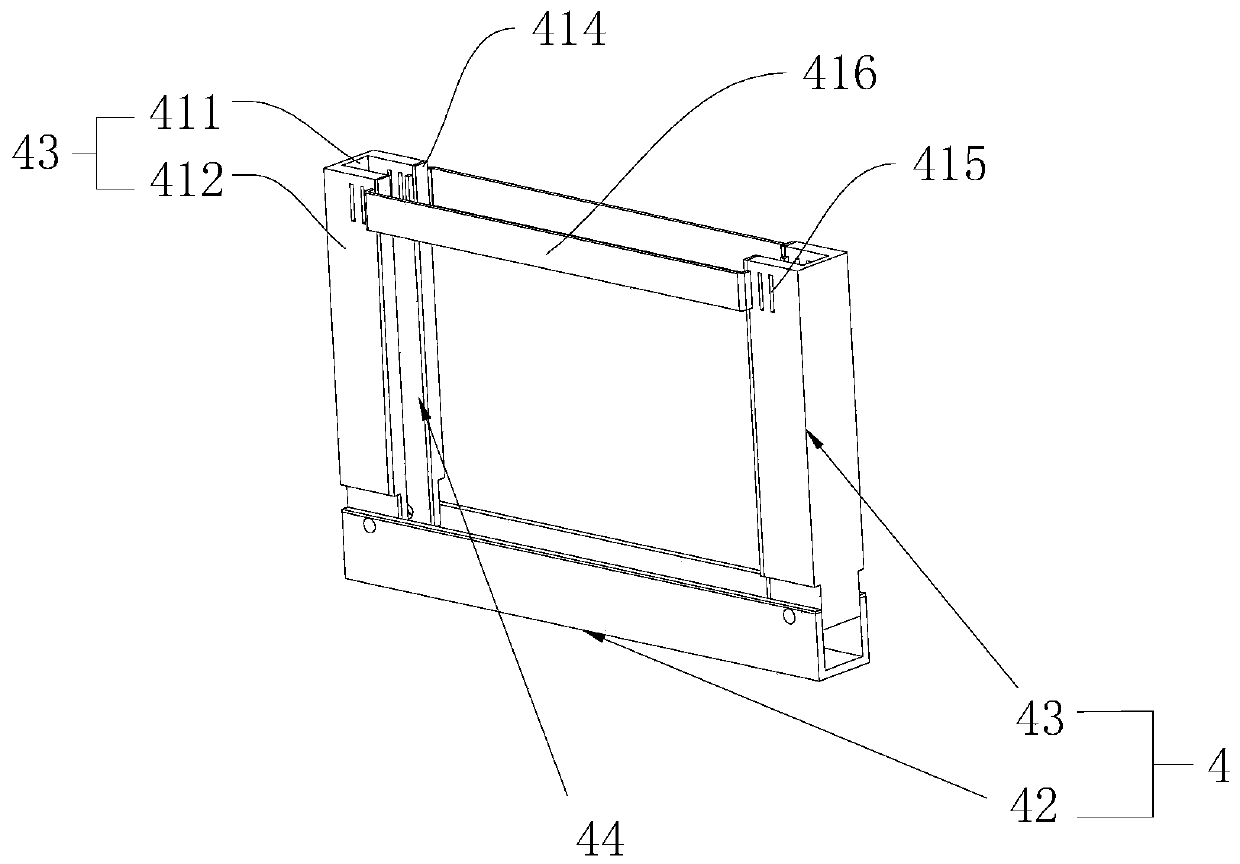

[0034] refer to figure 1, which is a wire saw cutting and dismantling method for foundation pit support support beam 1 disclosed by the present invention, including the steps of cutting and marking, support of support beam 1, internal force detection, cutting and removal, transfer in foundation pit, and off-site crushing of support beam 1, etc. During the process of cutting and removing the support beam 1, a diamond cutting device is used to cut the support beam 1.

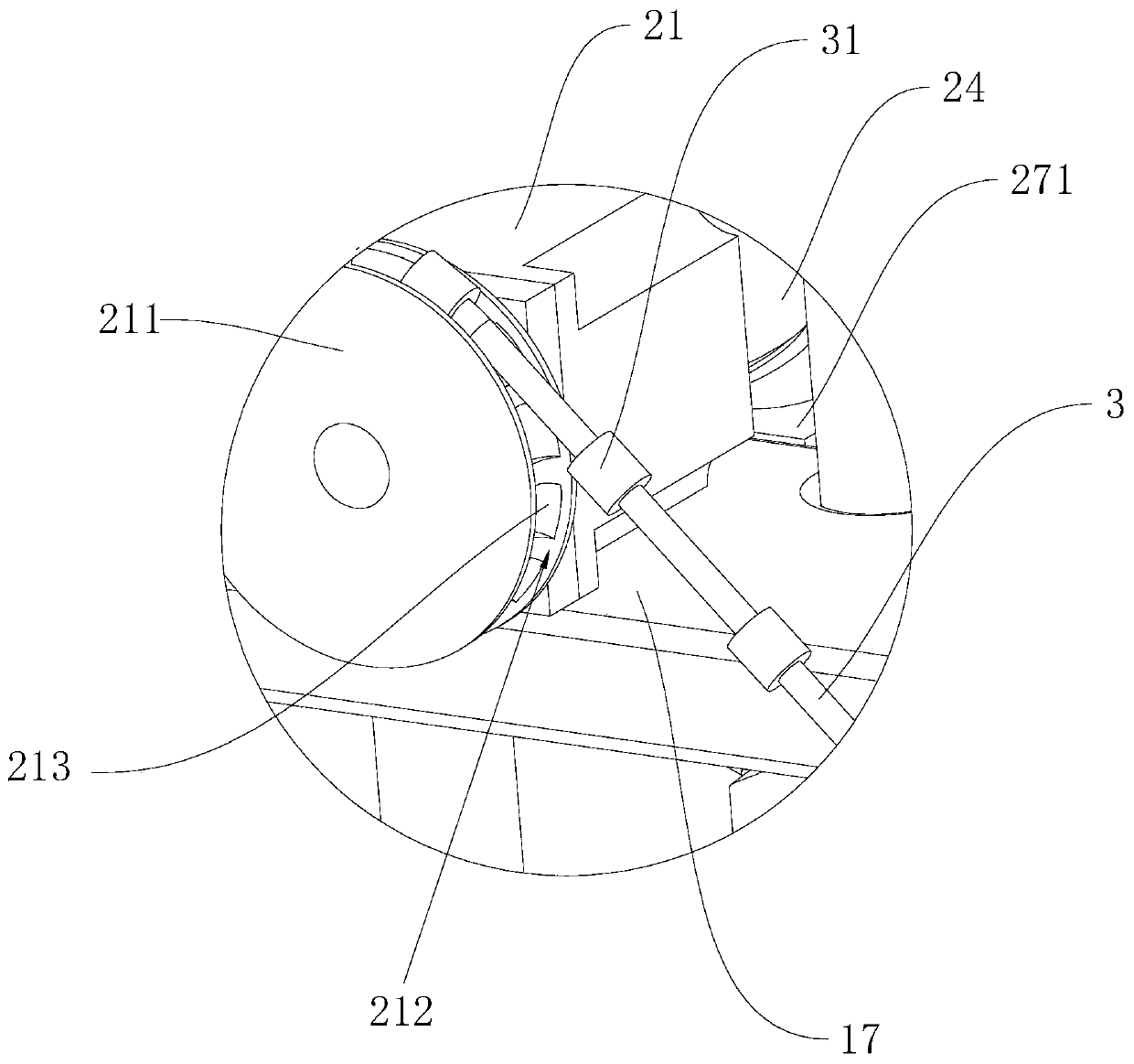

[0035] The diamond cutting device includes a support frame 2 , a diamond rope 3 and a driving motor 21 driving the diamond rope 3 for cutting. The driving motor 21 is located on the support frame 2 .

[0036] combine figure 1 and figure 2 It can be seen that the support frame 2 is vertically placed, and the two ends of the support frame 2 along the vertical direction are respectively fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com