Special grouting material for bridge repair

A grouting material and bridge technology, which is applied in the field of bridge repair, can solve problems such as bridge structure damage, and achieve the effects of increasing service life, reducing dry shrinkage, and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

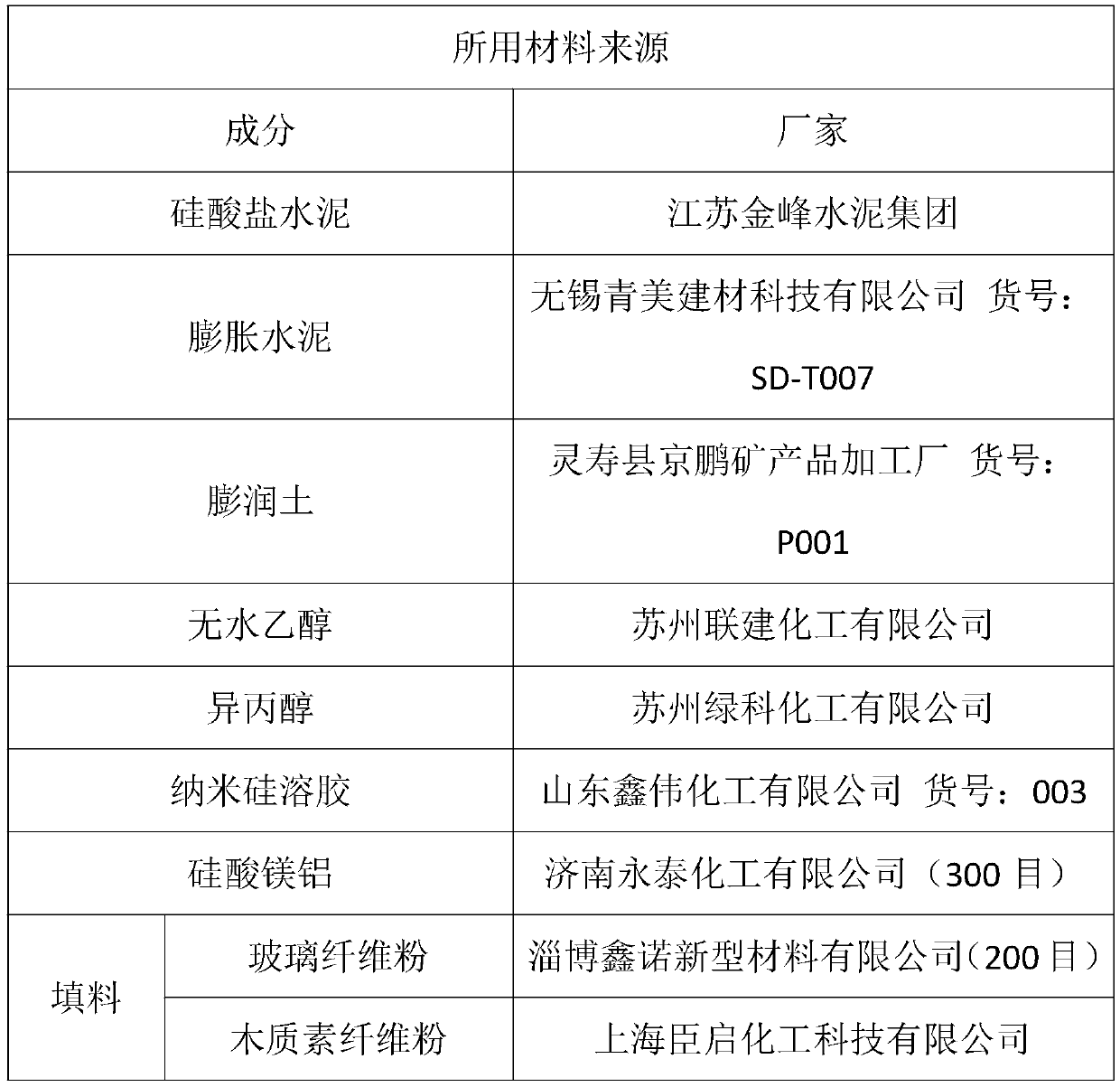

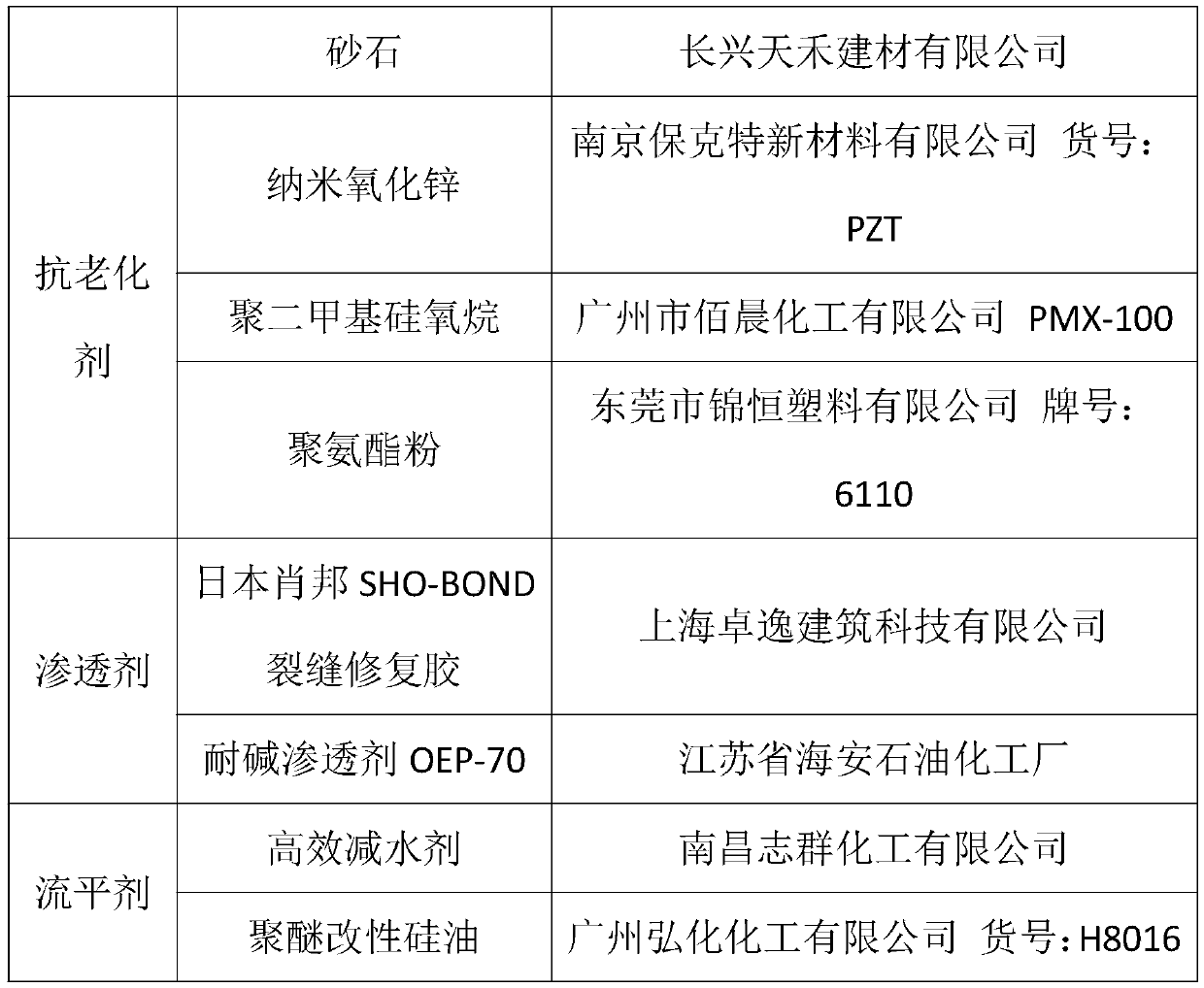

Method used

Image

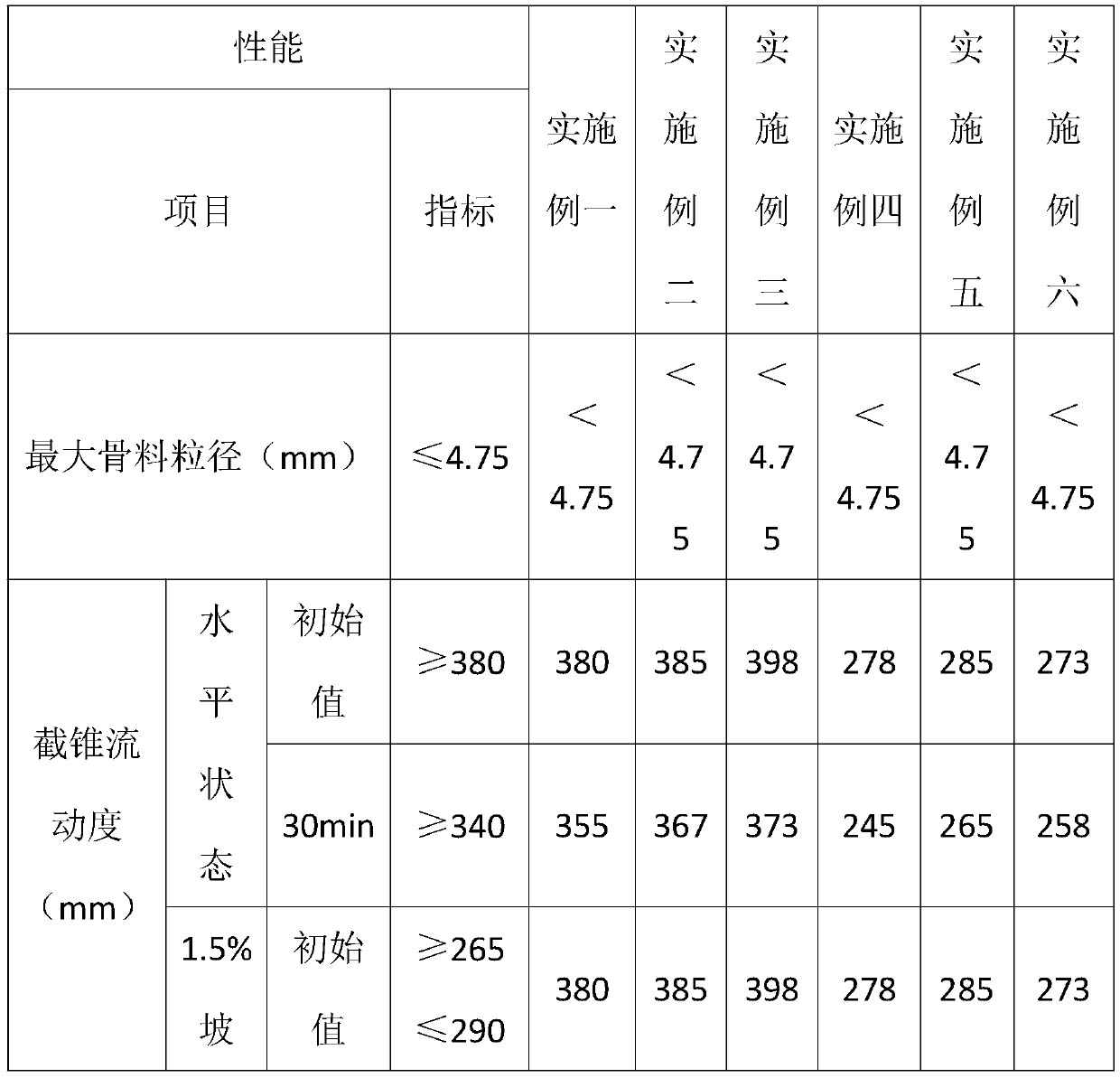

Examples

Embodiment 1

[0034] A special grouting material for bridge repair. The raw materials include the following components by weight: 55 parts of Portland cement, 6 parts of expansive cement, 6 parts of bentonite, 9 parts of absolute ethanol, 10 parts of isopropanol, and 12 parts of nano-silica sol , 9 parts of magnesium aluminum silicate, 18 parts of filler, 5 parts of penetrating agent, 4 parts of leveling agent, 5 parts of anti-aging agent, and 100 parts of water.

[0035] in:

[0036] The filler includes the following components in parts by weight: 20 parts of glass fiber powder, 15 parts of lignin fiber powder, and 10 parts of sand. And the particle size of the sand and gravel is 80 mesh and 180 mesh respectively, and the dosage ratio of the two sizes of sand and gravel is 1:2.

[0037] The penetrating agent includes the following components by weight: 20 parts of Japanese Chopin SHO-BOND crack repair glue, and 20 parts of alkali-resistant penetrating agent OEP-7000.

[0038] The leveling ...

Embodiment 2

[0044] A special grouting material for bridge repair. The raw materials include the following components by weight: 68-parts of silicate water, 7 parts of expansive cement, 6 parts of bentonite, 12 parts of absolute ethanol, 12 parts of isopropanol, and 16 parts of nano-silica sol 10 parts of magnesium aluminum silicate, 22 parts of filler, 6 parts of penetrating agent, 5 parts of leveling agent, 7 parts of anti-aging agent, and 120 parts of water.

[0045] in:

[0046] The filler comprises the following components in parts by weight: 22 parts of glass fiber powder, 18 parts of lignin fiber powder, and 12 parts of gravel. And the particle size of sand and gravel is 100 mesh and 190 mesh respectively, and the dosage ratio of the two sizes of sand and gravel is 1:2.

[0047] The penetrating agent includes the following components by weight: 23 parts of Japanese Chopin SHO-BOND crack repair glue, and 18 parts of alkali-resistant penetrating agent OEP-700.

[0048] The leveling ...

Embodiment 3

[0054] A special grouting material for bridge repairing raw materials includes the following components by weight: 69 parts of Portland cement, 7 parts of expansive cement, 8 parts of bentonite, 13 parts of absolute ethanol, 14 parts of isopropanol, 17 parts of nano-silica sol, silicon 12 parts of magnesium aluminum acid, 23 parts of filler, 8 parts of penetrating agent, 6 parts of leveling agent, 8 parts of anti-aging agent, 130 parts of water.

[0055] in:

[0056] The filler includes the following components in parts by weight: 30 parts of glass fiber powder, 20 parts of lignin fiber powder, and 15 parts of sandstone. And the particle size of sand and gravel is 120 mesh and 200 mesh respectively, and the dosage ratio of the two sizes of sand and gravel is 1:3.

[0057] The penetrating agent includes the following components by weight: 30 parts of Japanese Chopin SHO-BOND crack repair glue, and 1 part of alkali-resistant penetrating agent OEP-7021.

[0058] The leveling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com