Polyurethane high-resilience foam and preparation method thereof

A high-resilience, polyurethane technology, applied in the field of polyurethane materials, can solve the problems of low filling and poor tear resistance, achieve high bearing performance, high tear resistance, and improve product tearing capacity and bearing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

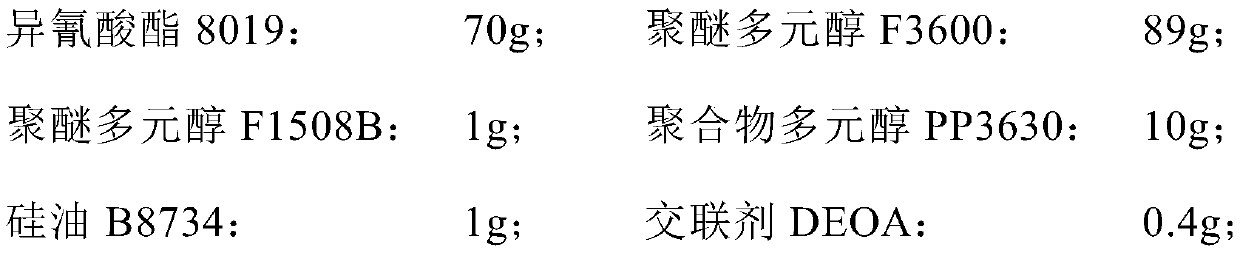

[0059] A kind of polyurethane high resilience foam, its raw material is as follows:

[0060]

[0061]

[0062] The preparation method of above-mentioned polyurethane high resilience foam is as follows:

[0063] (1) Take each raw material respectively according to the above-mentioned consumption;

[0064] (2) Take polyether polyol F3600, polyether polyol F1508B, polymer polyol PP3630, silicone oil B8734, crosslinking agent DEOA, water, organotin catalyst T12, amine catalyst A1, amine catalyst A33 and dodecane Sodium sulfonate is put into a cup, stirred at 2500r / min for 60s, poured into industrial grade calcium carbonate, stirred at 2500r / min for 60s to obtain the first mixture;

[0065] (3) Pour isocyanate 8019 into the first mixture obtained in step (2), and stir at 2500r / min for 7s to obtain the second mixture;

[0066] (4) Pour the second mixture obtained in the step (3) into a foam container quickly, and after the foam is completely solidified, ripen at room tempera...

Embodiment 2

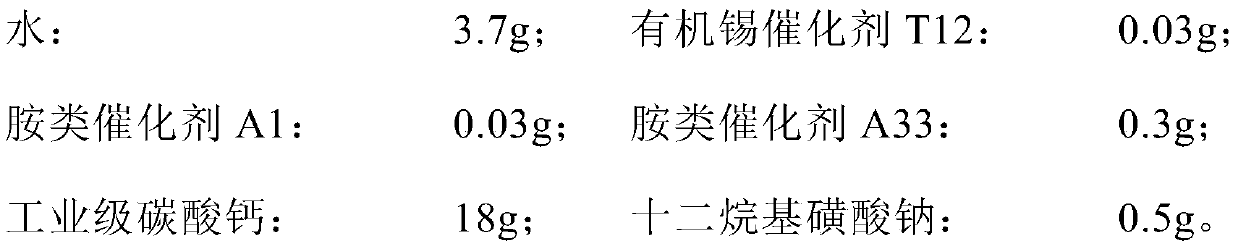

[0068] A kind of polyurethane high resilience foam, its raw material is as follows:

[0069]

[0070] The preparation method of above-mentioned polyurethane high resilience foam is as follows:

[0071] (1) Take each raw material respectively according to the above-mentioned consumption;

[0072] (2) Take polyether polyol F3600, polyether polyol F1508B, polymer polyol PP3630, silicone oil B8734, crosslinking agent DEOA, water, organotin catalyst T12, amine catalyst A1, amine catalyst A33 and dodecane Sodium sulfonate is put into a cup, stirred at 2500r / min for 60s, poured into industrial grade calcium carbonate, stirred at 2500r / min for 60s to obtain the first mixture;

[0073] (3) Pour isocyanate 8019 into the first mixture obtained in step (2), and stir at 2500r / min for 7s to obtain the second mixture;

[0074] (4) Pour the second mixture obtained in the step (3) into a foam container quickly, and after the foam is completely solidified, ripen at room temperature for 48 ...

Embodiment 3

[0076] A kind of polyurethane high resilience foam, its raw material is as follows:

[0077]

[0078] The preparation method of above-mentioned polyurethane high resilience foam is as follows:

[0079] (1) Take each raw material respectively according to the above-mentioned consumption;

[0080] (2) Take polyether polyol F3600, polyether polyol F1508B, polymer polyol PP3630, silicone oil B8734, crosslinking agent DEOA, water, organotin catalyst T12, amine catalyst UC300, amine catalyst D60 and dodecane Sodium sulfonate is put into a cup, stirred at 2500r / min for 60s, poured into industrial grade calcium carbonate, stirred at 2500r / min for 60s to obtain the first mixture;

[0081] (3) Pour isocyanate 8019 into the first mixture obtained in step (2), and stir at 2500r / min for 7s to obtain the second mixture;

[0082] (4) Pour the second mixture obtained in the step (3) into a foam container quickly, and after the foam is completely solidified, ripen at room temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com