Construction method and construction system for FRP reinforcement

A construction method and traction system technology, applied in the direction of bridge reinforcement, erection/assembly of bridges, bridge materials, etc., can solve the problems that the preparation work is difficult to complete conveniently, efficiently, and accurately, so as to realize automation and intelligence, reduce system weight, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

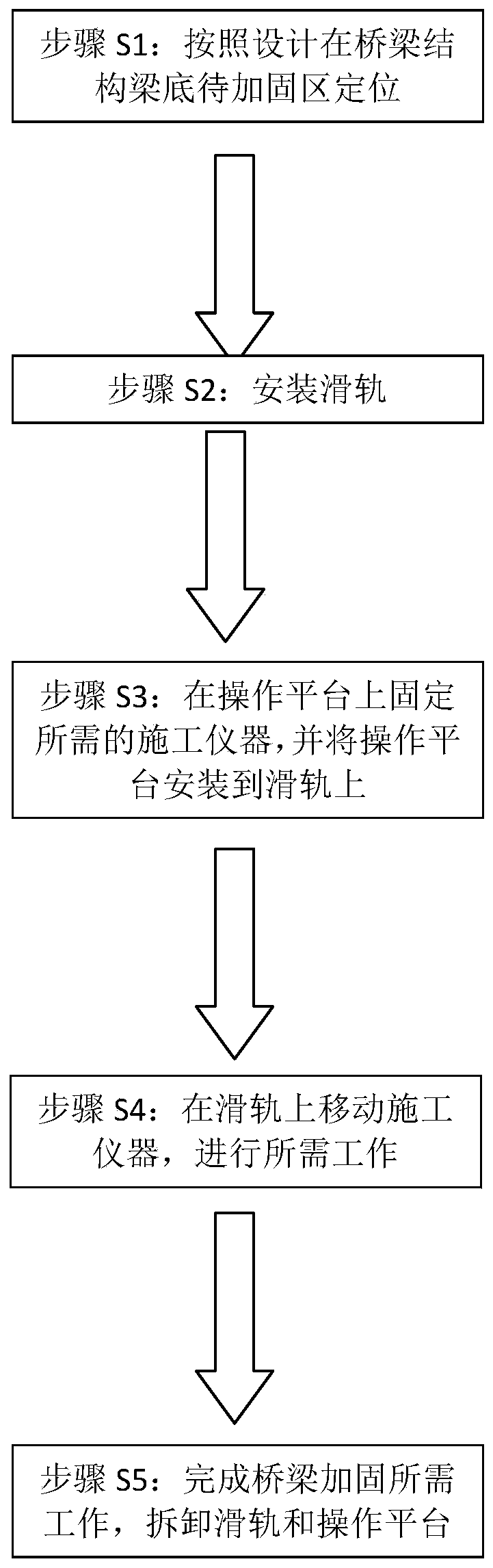

[0036] Such as figure 1 Shown, take being applied to prestressed concrete box girder bridge as example, a kind of FRP reinforced construction method of the present invention comprises the following steps:

[0037] S1: Locate the area to be reinforced of the bridge structure, design the drilling position on both sides of the area to be reinforced, then use a percussion drill to drill holes at the drilling position, and insert bolts in the holes. In this step, it should be ensured that the drilling position is not too close to the edge of the beam and will not damage the steel bar.

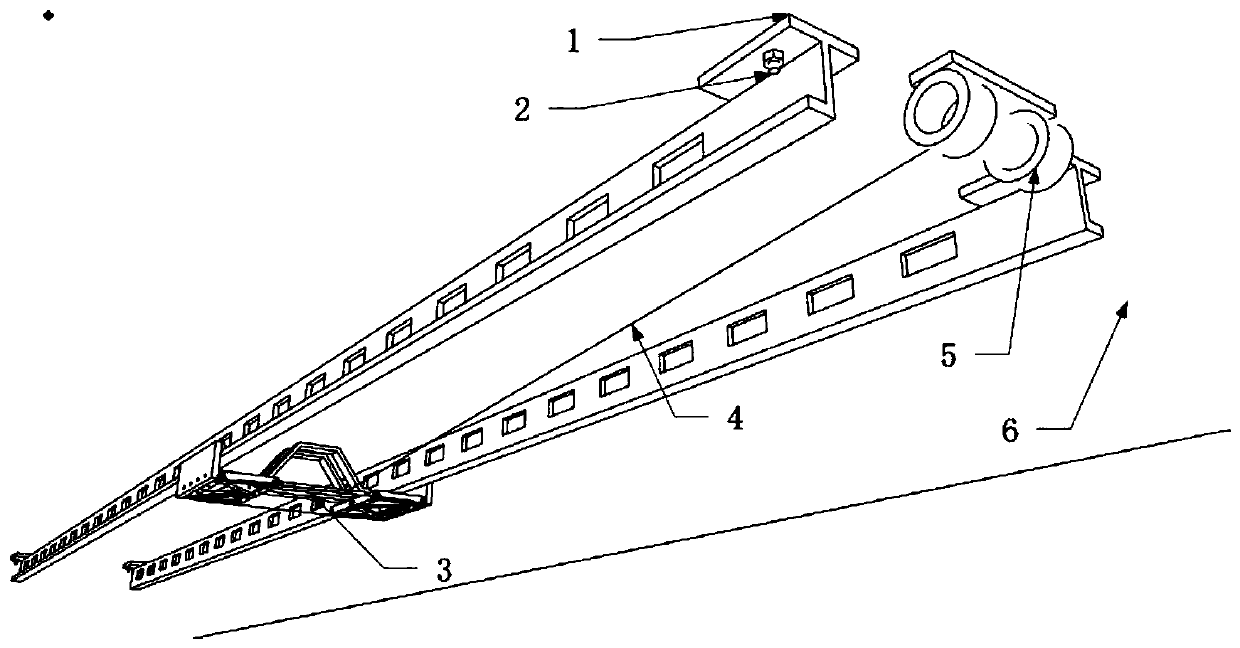

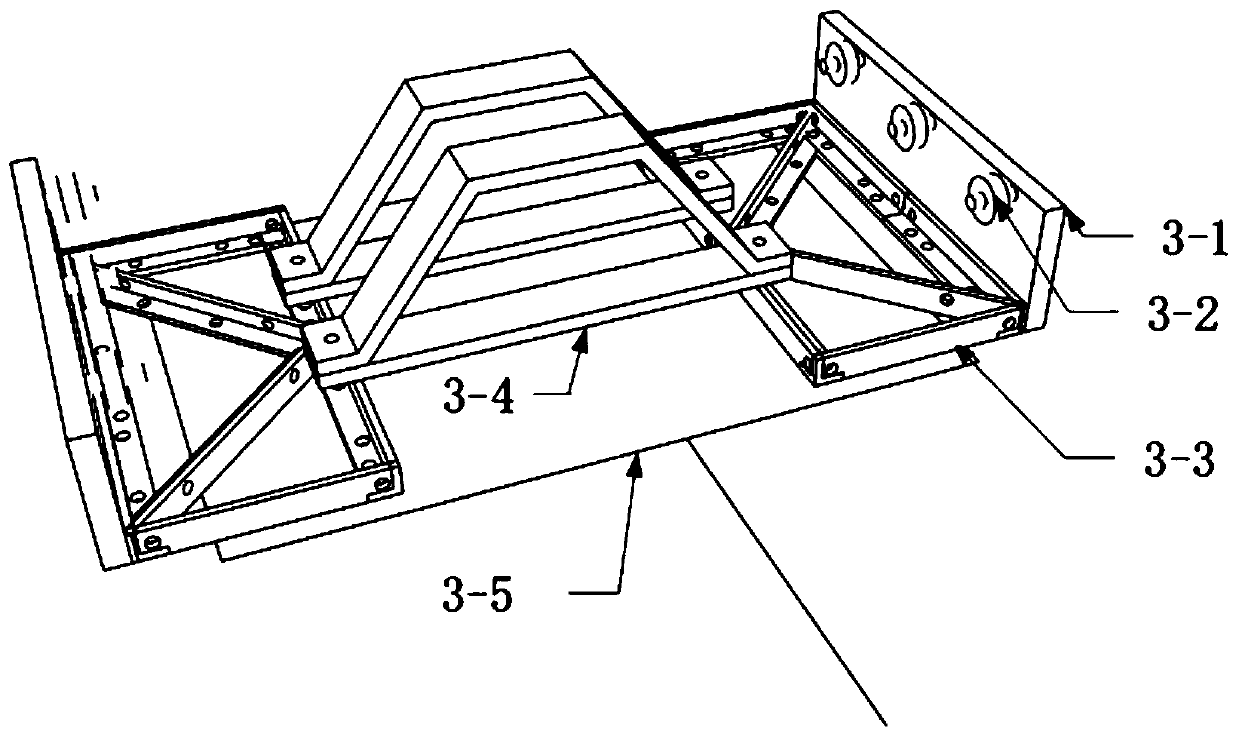

[0038] S2: Install the slide rail; place the slide rail at the designed position, and fix the slide rail 1 with the bolt 2. If the area to be reinforced is too long, multi-section slide rails can be installed, and the slide rails should be set on the same straight line to form a coherent sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com