Automatic treatment method for two-single-oil-pipe one-upright pillar drilling rig string

A processing method and column technology, which is applied in the direction of drill pipe, drill pipe, casing, etc., can solve the time-consuming problems of column establishment, and achieve the effect of increasing the space of the drill floor, improving operation efficiency, and good vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

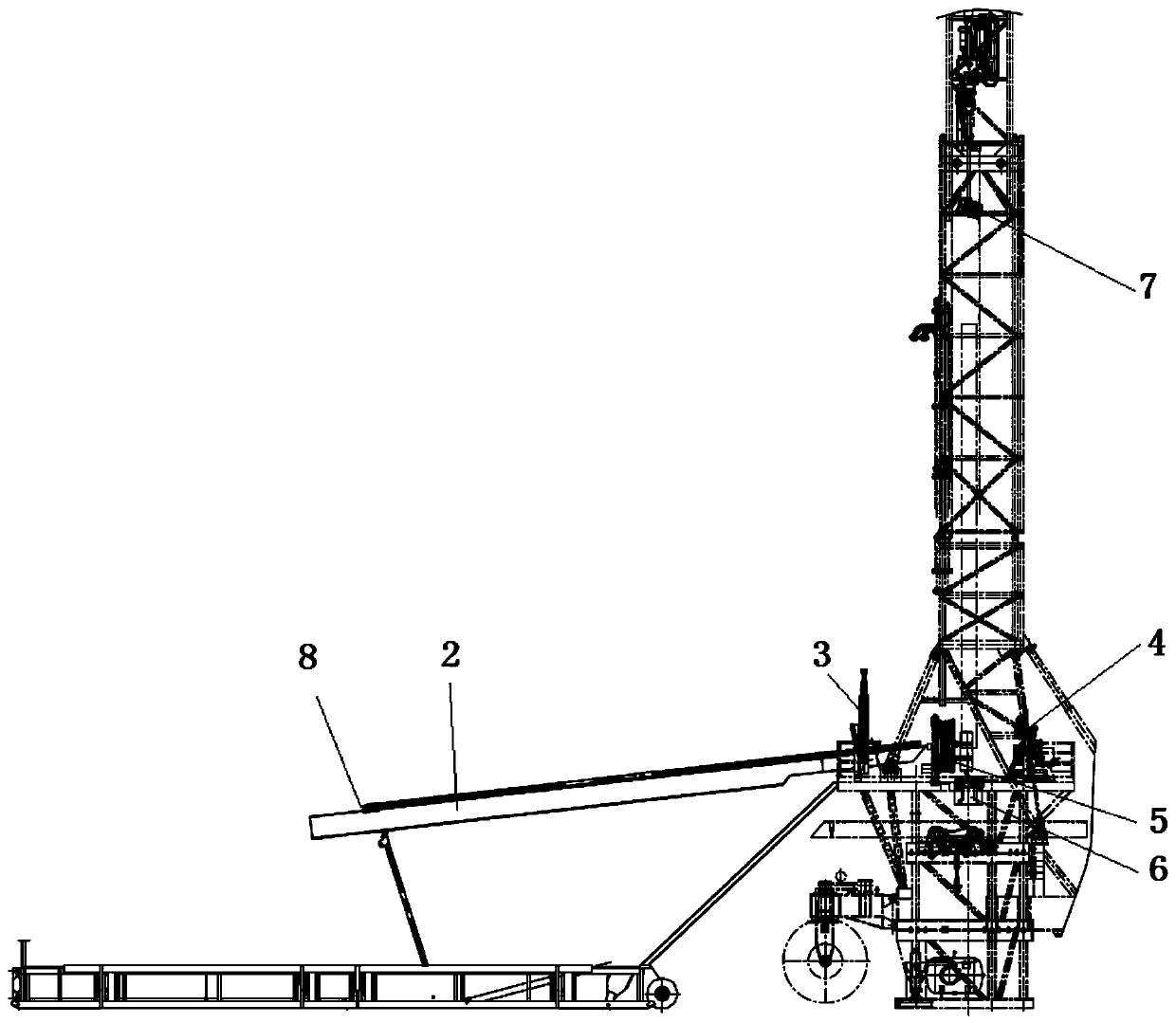

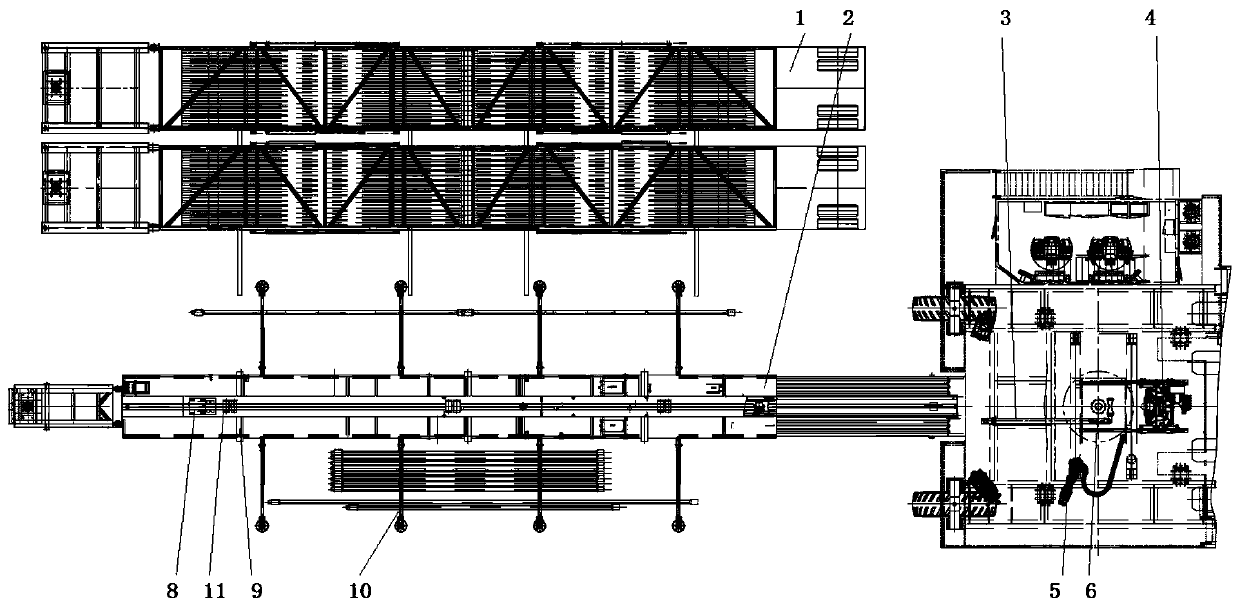

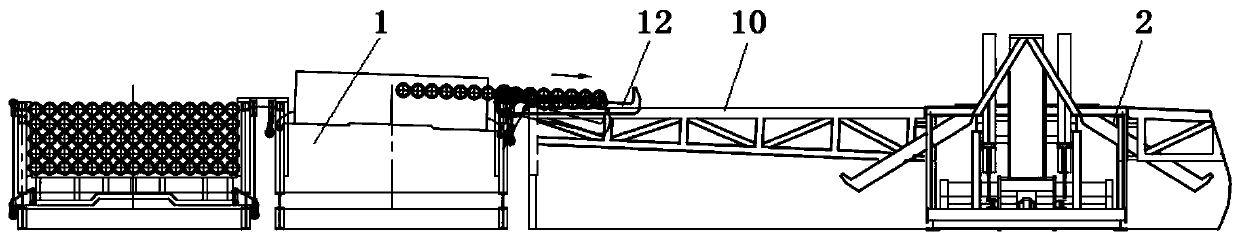

[0029] The present invention is a kind of automatic processing method of 2 single 1 column drilling rig strings, its structure is as follows Figure 1-2 As shown, on the ground in front of the drilling rig, a power drill rod box 1 and a power catwalk 2 are arranged side by side, and a buffer manipulator 3 is installed on the drilling rig deck, and an iron driller 4, a mud blowout prevention box 5, The power elevator 6 and the iron driller 4 are installed in the area between the mouse hole and the wellhead, the power slip 6 is installed in the turntable of the drilling rig, the power elevator 7 is suspended on the lifting ring of the drilling rig traveling crane system, and the power drill pipe box 1 stores the built 2 single 1 columns, and the power catwalk 2 is used to transport 2 single 1 columns.

[0030] Power catwalk 2 comprises catwalk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com