Pneumatic high-speed cupping test device and system

A cupping test, high-speed technology, applied in measuring devices, devices that measure the time required to move a certain distance, radio wave measurement systems, etc., can solve problems such as insufficient air pressure, unstable impact speed, and difficulty in evaluating formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

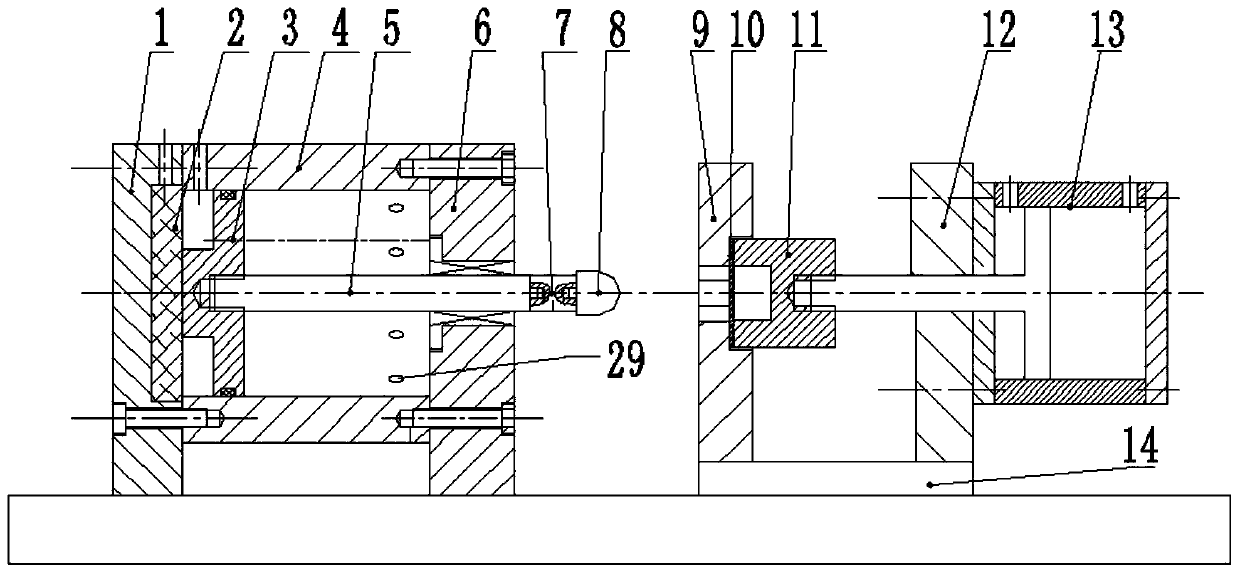

[0040] This embodiment provides a pneumatic high-speed cupping test device, including a punching device and a pressing device, such as figure 2 As shown, the punching device and the pressing device are arranged at a certain distance apart, and the distance between the two can be selected according to the impact depth requirements on the test piece 10 .

[0041] Specifically, the stamping device includes a cylinder 4, a first end cover 1, a second end cover 6, an electromagnet 2, a piston 3, a piston rod 5 and a punch 8, and one end of the cylinder 4 is detachably connected to the first end cover 1. , and the other end is detachably connected with the second end cover 6 . In this embodiment, the cylinder barrel 4 is connected with the first end cover 1 and the second end cover 6 through bolts.

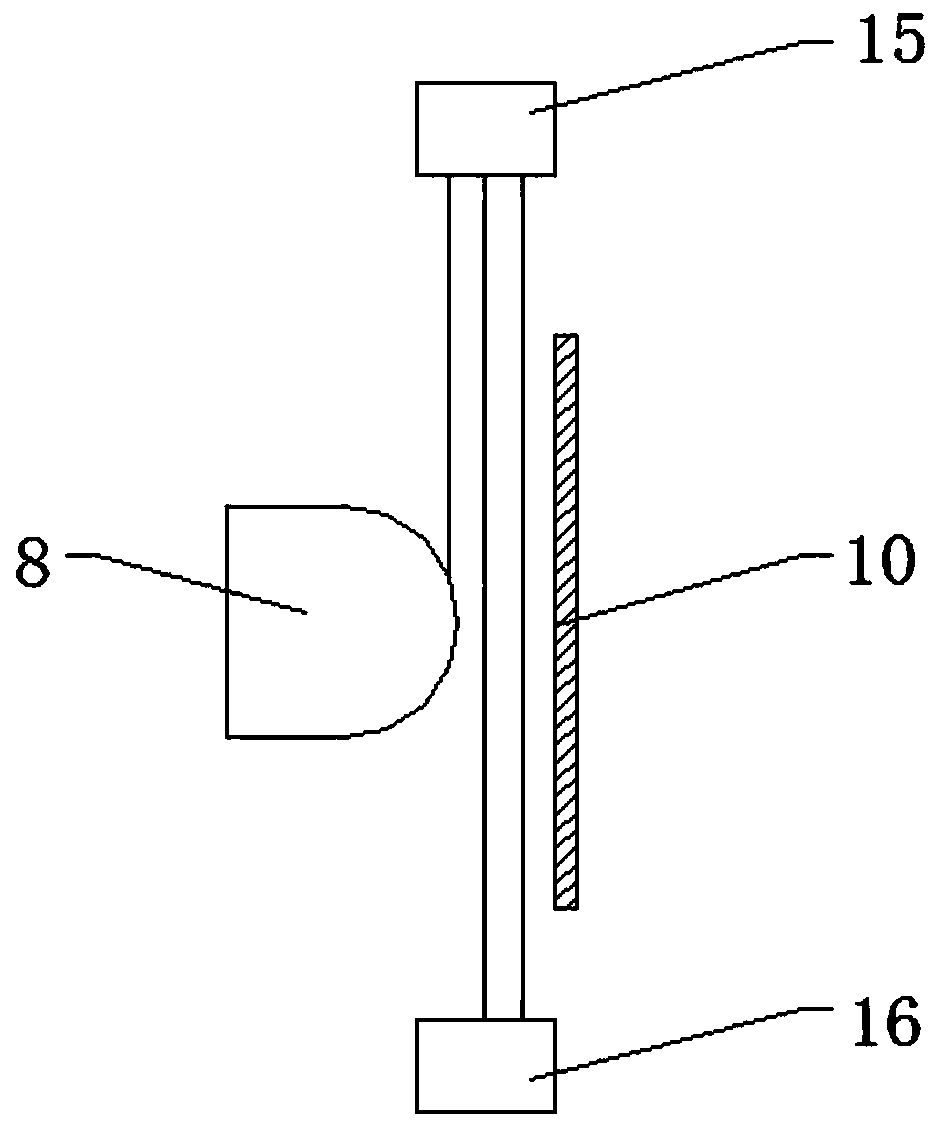

[0042] The electromagnet 2 is fixed inside the cylinder barrel 4, and further, as shown in Figure 4 (a) and Figure 4 (b), the inside of the first end cover 1 (near the cylinder barrel...

Embodiment 2

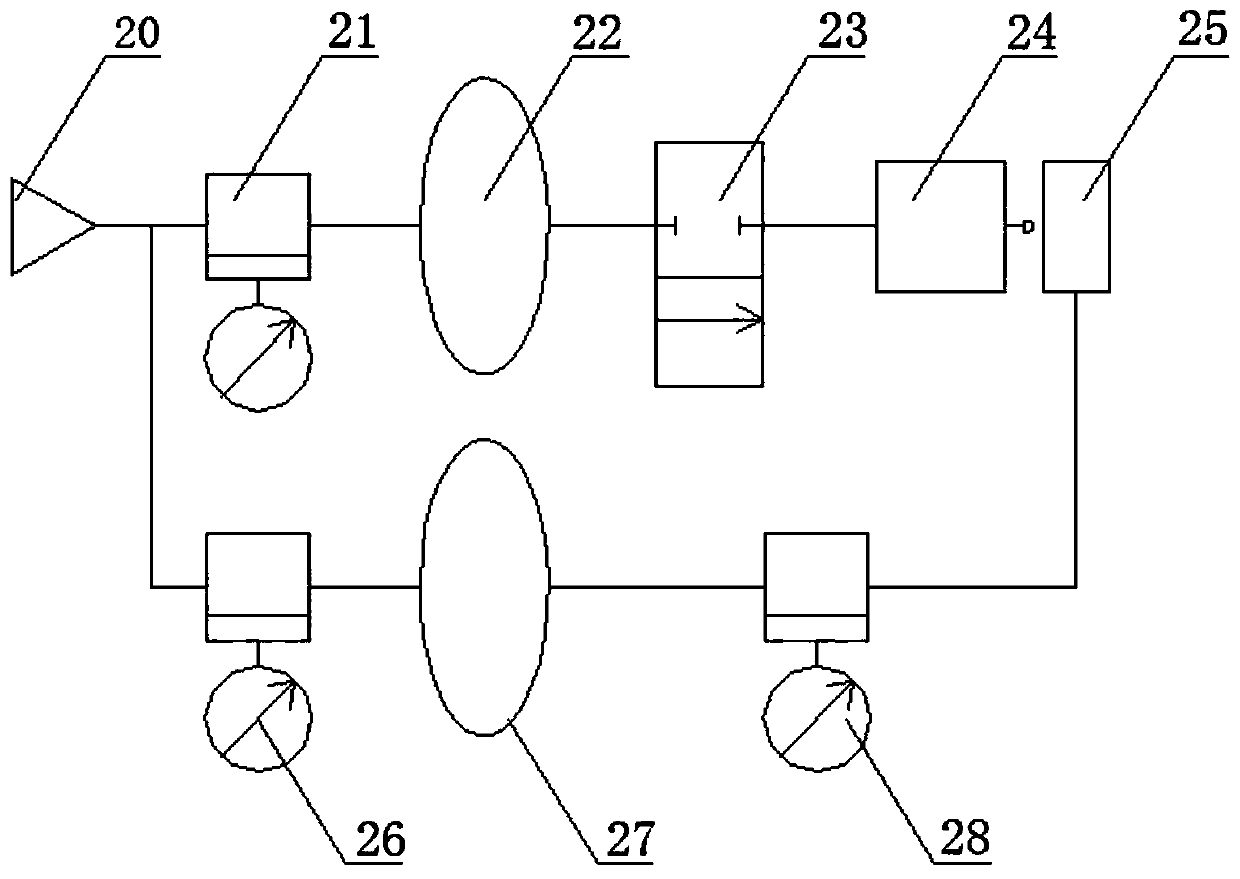

[0051] This embodiment provides a pneumatic high-speed cupping test system, including the test device described in the first embodiment, the punching device 24 and the pressing device 25 are respectively connected to the high-pressure air source 20 through pipelines.

[0052] Specifically, a first pressure regulating valve 21 , a first gas storage cylinder 22 , and a high-pressure solenoid valve 23 are sequentially installed on the pipeline connecting the high-pressure gas source 20 and the punching device 24 . The high-pressure gas source 20 is connected with the compression cylinder 13 through a pipeline, and a second pressure regulating valve 26 , a second gas storage cylinder 27 and an on-off valve 28 are installed on the pipeline in sequence.

[0053] The working principle of this embodiment is:

[0054] The high-pressure gas source 20 stores high-pressure gas, and outputs it to the first gas storage cylinder 22 through the first pressure regulating valve 21 , opens the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com