Lithium-ion battery high-voltage electrolyte for lithium nickel manganese oxide positive electrode material

A technology for lithium ion batteries and cathode materials, applied in battery electrodes, secondary batteries, organic electrolytes, etc., can solve the problems of inability to match high-voltage cathode materials, battery performance degradation, side reactions, etc., and achieve good cycle performance and cycle performance. The effect of enhancing and suppressing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A lithium-ion battery high-voltage electrolyte for lithium nickel manganese oxide cathode materials, including organic solvents, electrolyte lithium salts, by adding 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl) The amine co-solvent is obtained by modifying the conventional electrolyte, and it is prepared according to the following steps:

[0013] a) The co-solvent is 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl)imide and ethylene carbonate (EC), diethyl carbonate (DEC), ethyl methyl carbonate ( EMC) The organic solvent composed of EMC) is mixed evenly, and the proportion of 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl)imide to the total mass is 5%, and the mass of EC:DEC:EMC The ratio is 5:2:3 to obtain a high-voltage electrolyte precursor.

[0014] b) Mix 1M lithium hexafluorophosphate with the electrolyte precursor solution evenly to obtain the target product.

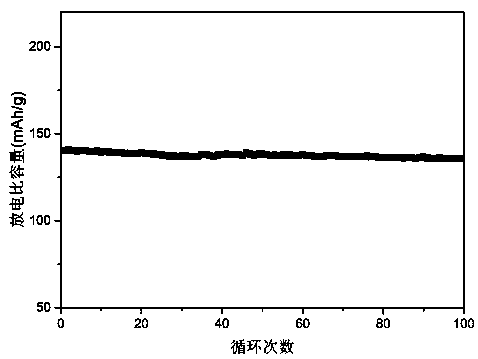

[0015] Such as figure 1 As shown, the half-cell cycle diag...

Embodiment 2

[0018] A kind of lithium ion battery high-voltage electrolyte that is used for lithium nickel manganese oxide cathode material, similar to embodiment 1, is prepared according to the following steps:

[0019] a) Mix 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl)imide with ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) Uniform, in which 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl)imide accounts for 3% of the total mass, and the mass ratio of EC:DEC:EMC is 1:1:1 , to obtain a high-voltage electrolyte precursor.

[0020] b) Mix 1M lithium hexafluorophosphate with the electrolyte precursor solution evenly to obtain the target product.

Embodiment 3

[0022] A lithium ion battery high-voltage electrolyte for lithium nickel manganese oxide positive electrode material, similar to Example 1, prepared according to the following steps:

[0023] a) Mix 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl)imide with ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) Uniform, wherein 1-tert-butyl-1-methylpiperidine bis(trifluoromethylsulfonyl)imide accounts for 1% of the total mass, and the mass ratio of EC:DEC:EMC is 5:3:3 , to obtain a high-voltage electrolyte precursor.

[0024] b) Mix 1M lithium hexafluorophosphate with the electrolyte precursor solution evenly to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com