Efficient antibacterial and antivirus copper-based filter screen with hierarchical structure and preparation method

A graded structure and high-efficiency technology, applied in water purification and antibacterial functions, environmental protection materials, with air purification field, can solve the problems of inconvenient air purification and copper ion loss of liquid antibacterial and disinfectant, and achieve the promotion of Cu ion release, increase in sterilization, etc. The effect of living efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

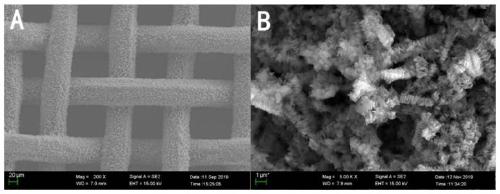

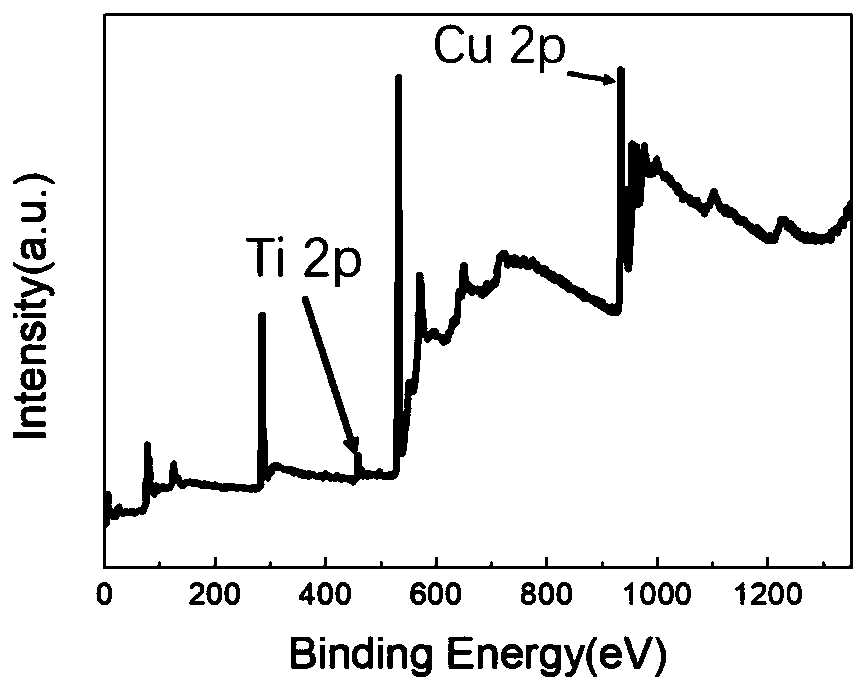

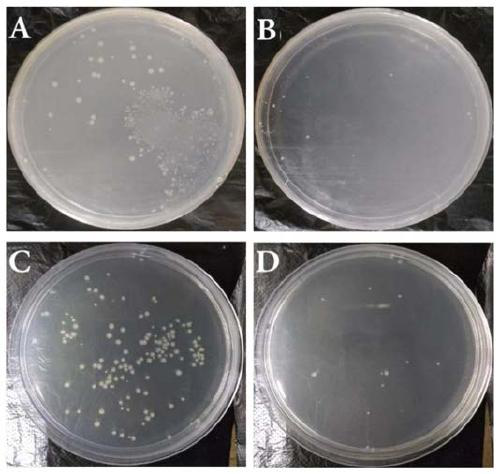

[0042]Embodiment 1: (1) copper mesh pretreatment: first preparation sodium hydroxide solubility is the mixed aqueous solution that 2.5mol / L and ammonium persulfate solubility are 0.13mol / L; Then pass through sulfuric acid, deionized water, Acetone ultrasonically cleaned copper mesh was immersed in the above solution for 30 minutes; rinsed with deionized water and dried at room temperature for use; (2) Preparation of surface modifier: first, 1 volume part of N-N dimethylformamide, 8 volume parts of deionized water and Mix 2 volumes of absolute ethanol and stir for 2 minutes, add 0.002 parts by mass of terephthalic acid, and stir for 2 minutes. (3) Preparation of metal-organic framework: firstly, the above-mentioned surface modification agent was heated to 70° C., and then the substrate was soaked in the surface modification agent to react for 20 minutes and then dried at 50° C. (4) Loading of nano-visible light photocatalytic materials: first absorb 1 part by volume of nano-tit...

Embodiment 2

[0043] Embodiment 2: (1) copper mesh pretreatment: first preparation sodium hydroxide solubility is the mixed aqueous solution that 2.5mol / L and ammonium persulfate solubility are 0.13mol / L; Then pass through sulfuric acid, deionized water, Acetone ultrasonically cleaned copper mesh was immersed in the above solution for 30 minutes; rinsed with deionized water and dried at room temperature for use; (2) Preparation of surface modifier: first, 1 volume part of N-N dimethylformamide, 10 volume parts of deionized water and Mix absolute ethanol with 0 volume and stir for 2 minutes, add 0.002 parts by mass of terephthalic acid, and stir for 2 minutes. (3) Preparation of metal-organic framework: firstly, the above-mentioned surface modification agent was heated to 70° C., and then the substrate was soaked in the surface modification agent to react for 20 minutes and then dried at 50° C. (4) Loading of nano-visible light photocatalytic materials: first absorb 1 part by volume of nano-...

Embodiment 3

[0044] Embodiment 3: (1) copper mesh pretreatment: first preparation sodium hydroxide solubility is the mixed aqueous solution that 2.5mol / L and ammonium persulfate solubility are 0.13mol / L; Then pass through sulfuric acid, deionized water, Acetone ultrasonically cleaned copper mesh was immersed in the above solution for 30 minutes; rinsed with deionized water and dried at room temperature for use; (2) Preparation of surface modifier: first, 1 volume part of N-N dimethylformamide, 10 volume parts of deionized water and Mix absolute ethanol with 0 volume and stir for 2 minutes, add 0.002 parts by mass of terephthalic acid, and stir for 2 minutes. (3) Preparation of metal-organic framework: first, the above-mentioned surface modification agent was heated to 70° C., and then the substrate was soaked in the surface modification agent to react for 10 minutes and then dried at 50° C. (4) Loading of nano-visible light photocatalytic materials: first absorb 1 part by volume of nano-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com