Rubber and plastic puncture-proof multifunctional shoe sole and preparation method thereof

A puncture-proof and multi-functional technology, which is applied in the direction of shoe soles, footwear, and other household appliances, etc., can solve the problems of EVA foam soles such as airtightness, slipping and grinding of soles, slipping and odor, etc., and achieve good anti-slip performance and surface Good smoothness and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

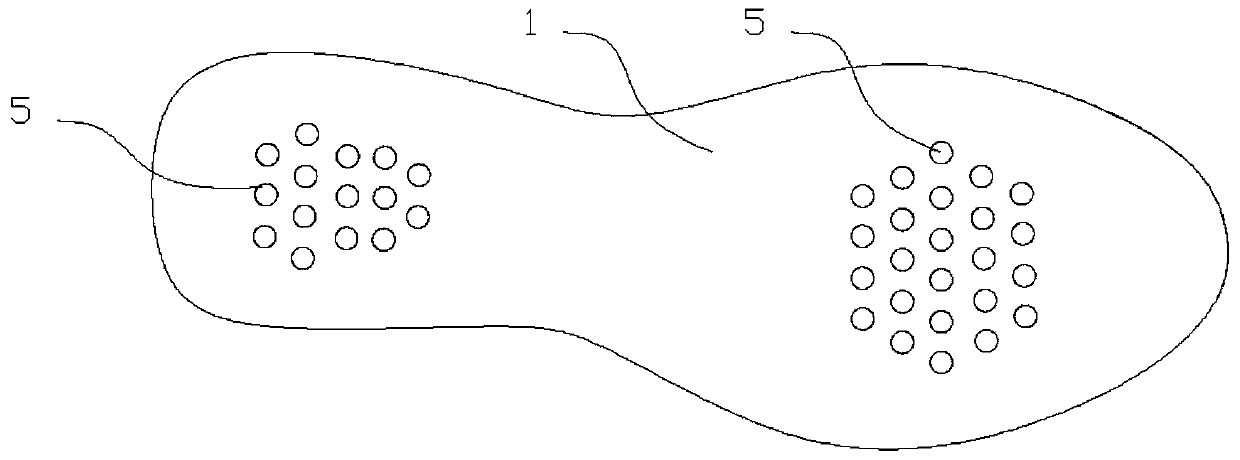

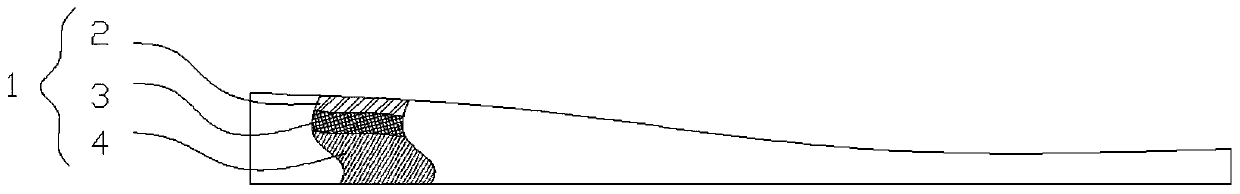

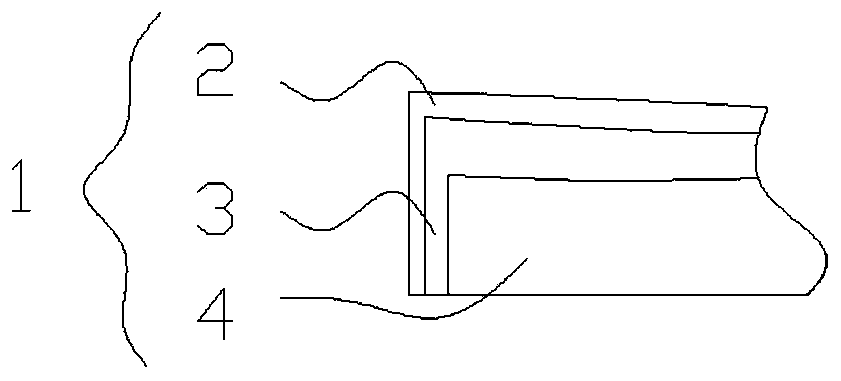

[0037] As shown in the figure, a rubber and plastic puncture-resistant multifunctional sole and its preparation method include a sole body 1, the sole body includes an upper, middle and lower three-layer structure, the upper layer is a contact layer 2, the middle is a protective layer 3, and the lower layer is a The elastic layer 4, the contact layer is a cork layer formed by cork particles, the protective layer is a puncture-resistant cloth filling layer, and the elastic layer is a composite layer of EVA and rubber.

[0038] In this embodiment, the cork layer is molded from cork particles, with a thickness of 1.2 mm and a hardness of Shore A38; the protective layer is a three-dimensional woven fabric with a thickness of 1.2 mm; the thickness of the elastic layer is 9.6 mm, The hardness is Shore A50. The three-dimensional weaving process of the protective layer achieves the technical effect of increasing the toughness and strength of a single layer several times. At the same t...

Embodiment 2

[0055] In this embodiment, the cork layer is molded from cork particles, with a thickness of 1.6 mm and a hardness of Shore A40; the protective layer is a three-dimensional woven cloth with a thickness of 1.8 mm; the thickness of the elastic layer is 10.5 mm. The hardness is Shore A60. The three-dimensional weaving process of the protective layer achieves the technical effect of increasing the toughness and strength of a single layer several times. At the same time, the sense of space is more abundant than that of ordinary textile processes, and the ventilation effect is better.

[0056] In this embodiment, the cork layer of the contact layer is a cork spliced surface material with a thickness of 1.6mm and a hardness of Shore A40; the thickness of the protective layer is 1.8mm; the thickness of the elastic layer is 10.5mm and a hardness of Shore A40. Seoul A60.

[0057] In this embodiment, the elastic layer is molded and foamed with EVA rubber-plastic elastomer, and the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com