Semi-circle assembling and welding method for shroud partition plate blade grids of steam turbine

A technology for steam turbines and partitions, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of poor radius size accuracy, poor weld quality, large welding volume, etc., to improve dimensional accuracy, improve welding quality, The effect of saving processing time and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

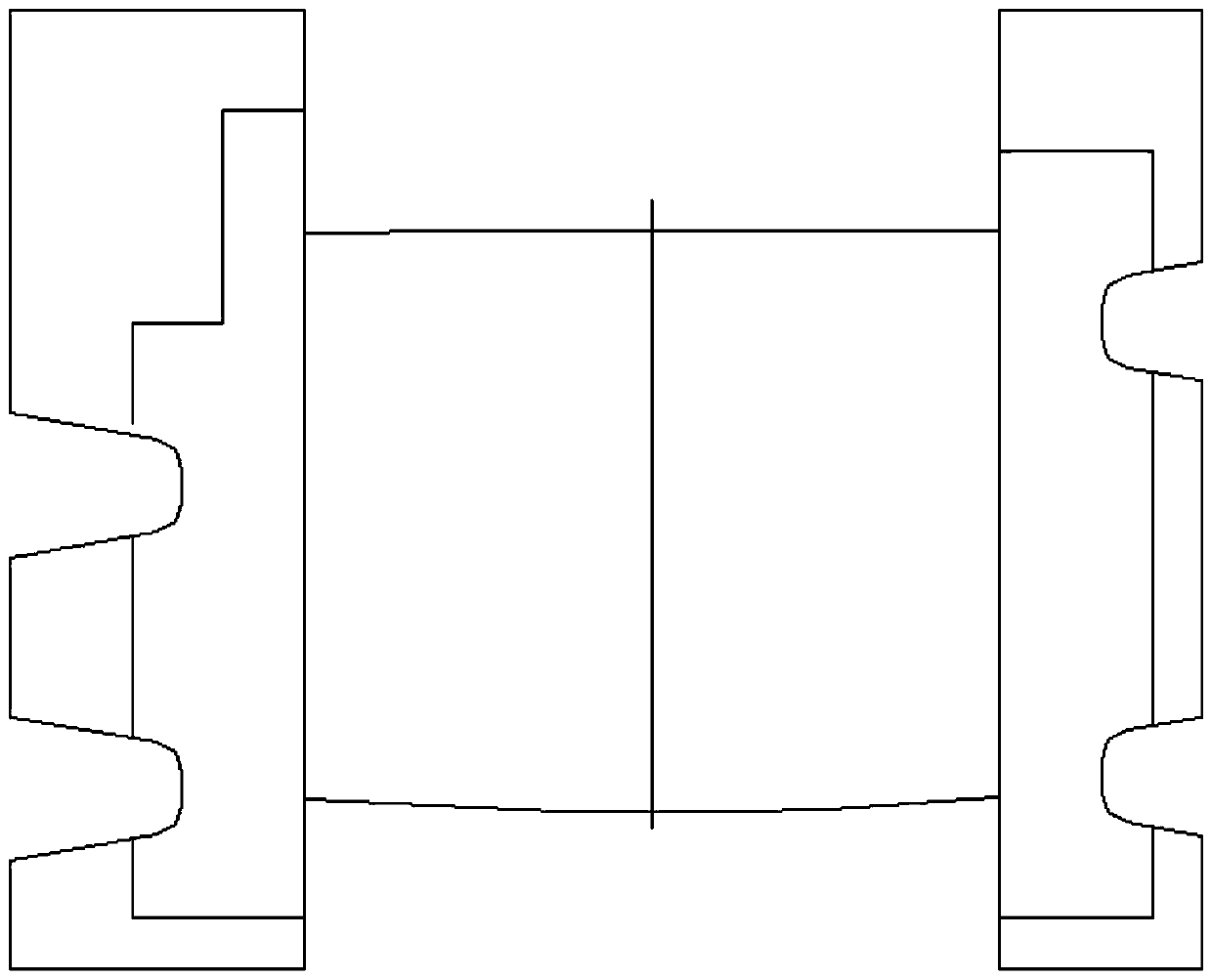

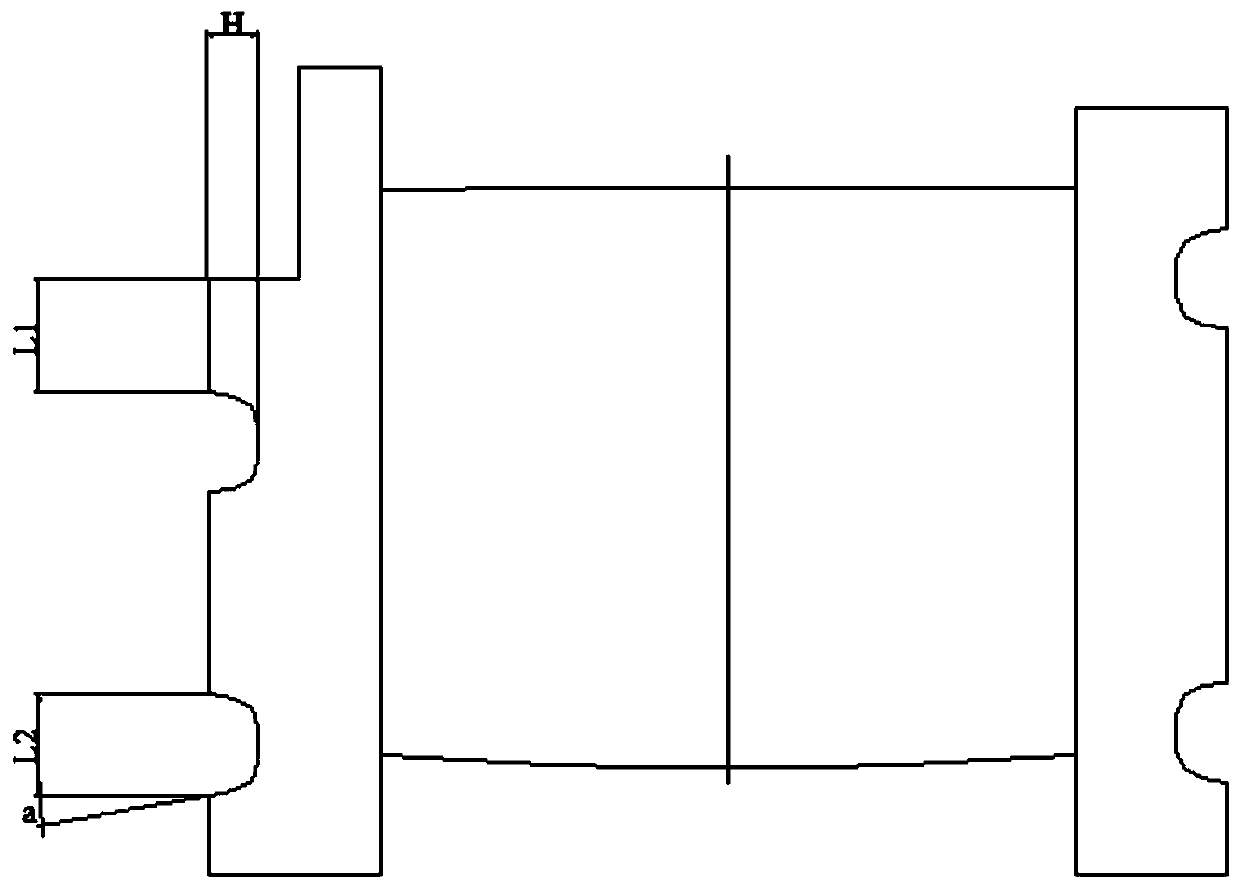

[0019] Specific implementation mode one: refer to figure 1 To illustrate this embodiment, this embodiment provides a method for assembling and welding a half-circle of a clapboard and cascade of a steam turbine with its own crown, and the method is realized through the following steps:

[0020] Step 1: Determine the required number N of guide vanes according to the size of the half-turn of the cascade and the size of a single guide vane, where N is a positive integer;

[0021] Step 2: Put the steam outlet side of the N guide vanes facing up in step 1, and place them on the special tooling for installing and welding the diaphragm static blade cascade in turn, and check that the dimensions of the diaphragm static blade cascade composed of the arranged guide vanes are correct. Cover the pressure ring and press it tightly;

[0022] Step 3: Use bolts to fasten one side of the diaphragm static blade cascade composed of guide vanes in step 2, and respectively place two Mark the pos...

specific Embodiment approach 2

[0030] Specific implementation mode two: refer to figure 1 Describe this embodiment, this embodiment is to further limit the step six described in the first specific embodiment, in this embodiment, in the step six, two Welding groove, the distance between the welding groove on both sides of the inner belt of the diaphragm static cascade and the finished surface is about 10mm, and the welding on both sides of the outer circumference of the diaphragm static blade cascade The distance between the bevel and the finished surface is about 10mm. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Specific implementation mode three: refer to figure 1 Describe this embodiment, this embodiment is to further limit the step six described in the second specific embodiment, in this embodiment, the welding groove width (distance from precision Processing surface) is 10mm. Other compositions and connection methods are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com