Method for treating neutralizing slag in building materials

A processing method and building material technology, applied in cement production, etc., can solve problems such as excessive setting time, increased cement water consumption, and affecting the workability of concrete slurry, so as to achieve increased slump, small water demand, and improved water quality. The effect of chemical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

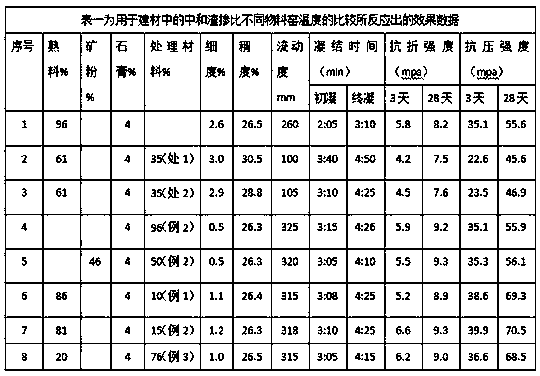

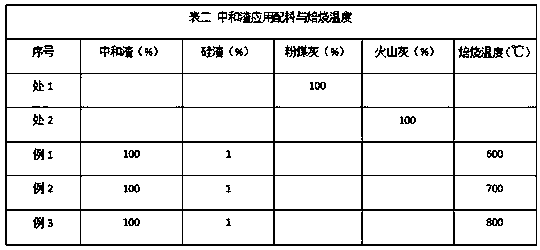

[0018] Embodiments are specifically shown in Table 1 and Table 2 and the description of Comparative Table 1.

[0019] The materials stacked into the kiln are hydrated until the crystal water contained is equal to or greater than 8%, and then they are roasted in the kiln. The kiln temperature of the roasted material is 1,600°C for example, 700°C for example 2, and 800°C for example 3.

[0020] Usually, when the material kiln temperature is as low as 600°C, this product will have a greater impact on the product quality, strength, and consistency setting time in the cement produced. When it is higher than 800°C, the product quality will not increase much, so The roasting temperature of this product should be controlled at 700±100°C. The water consumption of this product is relatively small, the setting time of cement or concrete is relatively normal, the consistency of cement is relatively low, and the fluidity of concrete is relatively good.

[0021]

[0022]

[0023] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com