Heat-resistant high-strength concrete for gradient enclosure structure and preparation method thereof

A technology of heat-resistant concrete and high-strength concrete, applied in the field of building materials, can solve the problem of rapid strength loss, and achieve the effects of improving the interface bonding force, avoiding high-temperature bursting, and promoting the degree of cement hydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

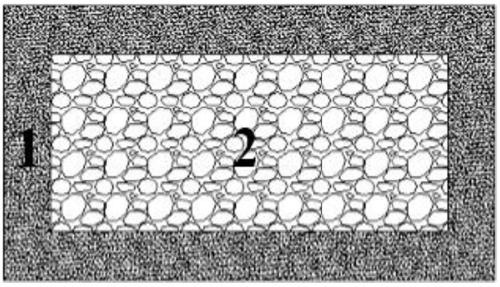

[0034] A heat-resistant high-strength concrete with a gradient maintenance structure, which is composed of an inner layer of high-strength heat-resistant concrete and an outer layer of high-heat-resistant concrete from the inside to the outside (see figure 1 ), where the ratio of the cross-sectional area of the outer layer of high heat-resistant concrete to the inner layer of high-strength heat-resistant concrete is 1:2.5. The mix proportions of the inner high-strength heat-resistant concrete and the outer high-heat-resistant concrete are shown in Table 1 and Table 2 respectively; the test results are shown in Table 3.

[0035] Table 1 The mix ratio of the inner high-strength heat-resistant concrete in Example 1 (kg / m 3 )

[0036]

[0037] Among them, shale ceramsite is used as the light aggregate for internal maintenance, and the bulk density is 830kg / m 3 , simple compressive strength 2.5Mpa, saturated with water 24 hours before the test to drain the water, the additio...

Embodiment 2

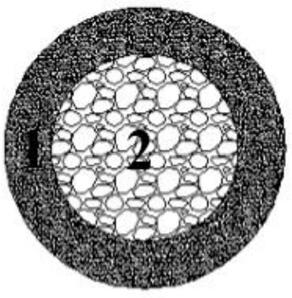

[0045] A heat-resistant high-strength concrete with a gradient maintenance structure, which is composed of an inner layer of high-strength heat-resistant concrete and an outer layer of high-heat-resistant concrete from the inside to the outside (see figure 2 ), wherein the ratio of the cross-sectional area of the outer layer of high heat-resistant concrete to the inner layer of high-strength heat-resistant concrete is 1:3.5; the mix ratios of the inner layer of high-strength heat-resistant concrete and the outer layer of high-heat-resistant concrete are shown in Table 4 and Table 5 respectively; The test results are shown in Table 6.

[0046] The mixing ratio of the inner high-strength heat-resistant concrete in Example 2 in Table 4 (kg / m 3 )

[0047]

[0048] Among them, shale ceramsite is used as light aggregate with a bulk density of 750kg / m 3 , simple compressive strength 3.0Mpa, saturated with water 24 hours before the test to drain the water, the addition amount ...

Embodiment 3

[0056] A heat-resistant high-strength concrete with a gradient maintenance structure, which is composed of an inner layer of high-strength heat-resistant concrete and an outer layer of high-heat-resistant concrete from the inside to the outside (see image 3 ), wherein the ratio of the cross-sectional area of the outer layer of high heat-resistant concrete to the inner layer of high-strength heat-resistant concrete is 1:3; the mix ratios of the inner layer of high-strength heat-resistant concrete and the outer layer of high-heat-resistant concrete are shown in Table 7 and Table 8 respectively; The test results are shown in Table 9.

[0057] The mixing ratio of the inner high-strength heat-resistant concrete in Example 3 in Table 7 (kg / m 3 )

[0058]

[0059] Among them, clay ceramsite is used as the light aggregate for internal maintenance, and the bulk density is 950kg / m 3 , simple compressive strength 3.5Mpa, saturated with water for 24 hours before the test to drain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com