Pile-turning and bin-transferring device for multi-connected dynamic tunnel type fermentation bin

A fermentation bin and tunnel-type technology, applied in fertilization devices, applications, preparation of organic fertilizers, etc., can solve the problems of poor system sealing, larger area and civil construction investment, and the inability of piling machines to have both material crushing and Shift function and other issues to achieve the effect of reducing the risk of action coordination errors, avoiding mutual obstruction and accident risks, and reducing the risk of odor pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

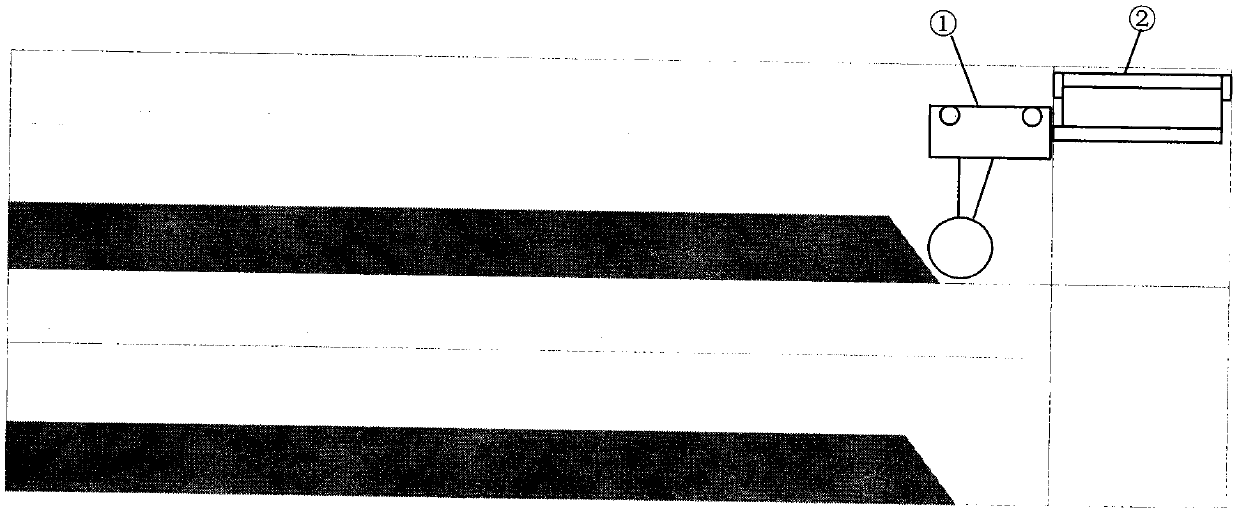

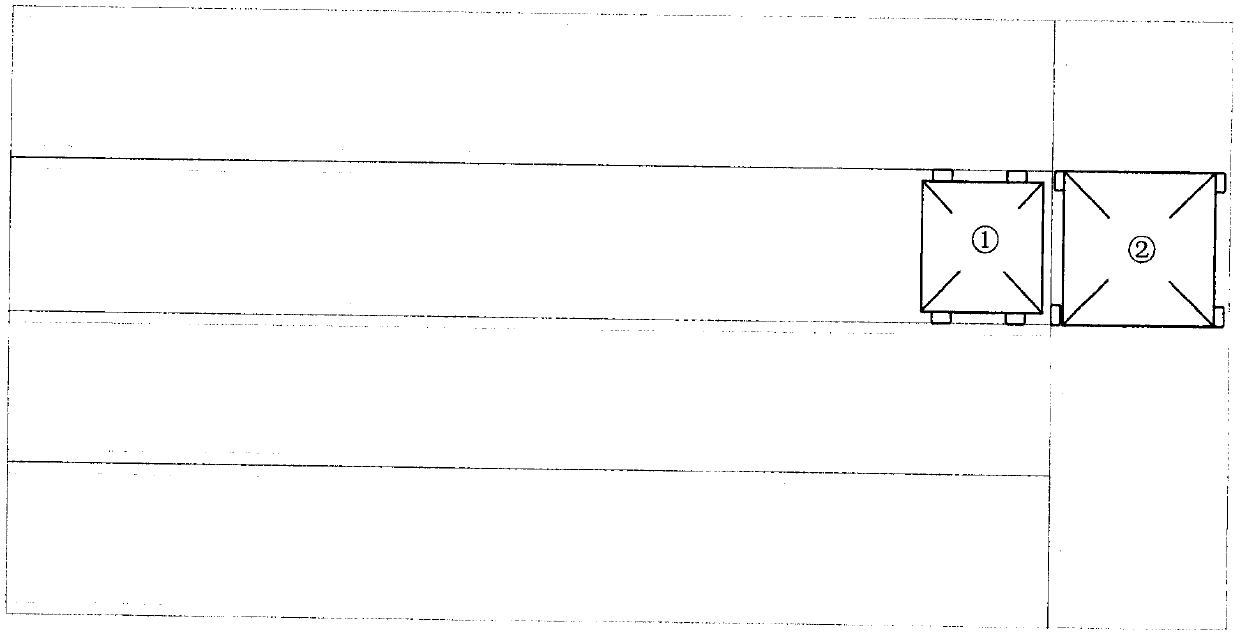

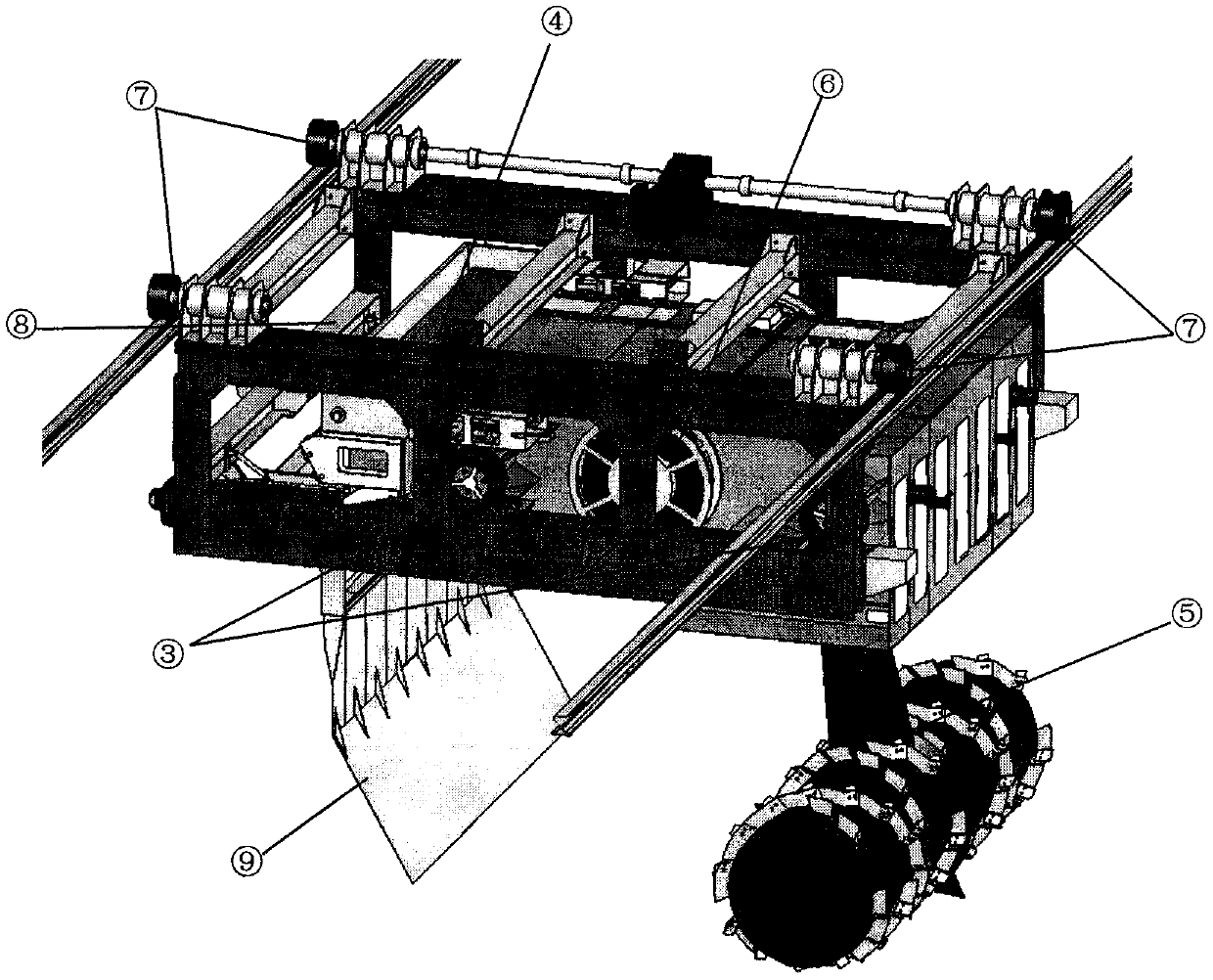

[0032] The structure and working process of a turning and turning device for multi-connected dynamic tunnel fermentation bins according to the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The turner 2 carries the compost turner 1 by relying on the turner walking mechanism 7 to walk on the sky rail perpendicular to the dynamic tunnel-type fermentation bin, and arrives at the end of the predetermined dynamic tunnel-type fermentation bin. Positively, the electronic control system 8 of the turner sends a signal to the control system 4 of the turner and provides power. 1 Enter the dynamic tunnel-type fermentation bin, and at the same time drive the mud-stop mechanism 9 of the transfer bin machine to reach the bin opening to form a shielding state, put down the roller turning mechanism 5, start turning and move to the head of the dynamic tunnel-type fermentation bin, and the materials are in the roller turning mechanism Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com