A kind of separation and purification method of gamma cyclodextrin

A gamma cyclodextrin, separation and purification technology, applied in the field of drug separation and purification, can solve the problems of inability to achieve secondary purification, large solvent consumption, and high purification cost, and achieve environmental protection, instrument cost saving, and separation efficiency that are beneficial to the solvent. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

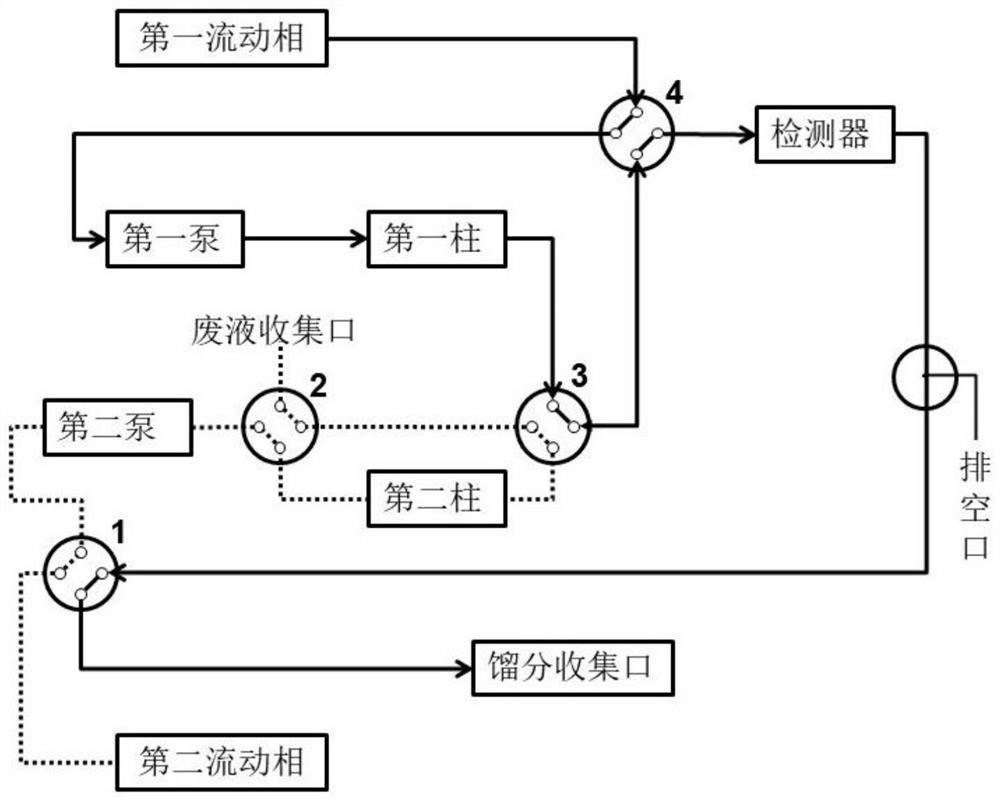

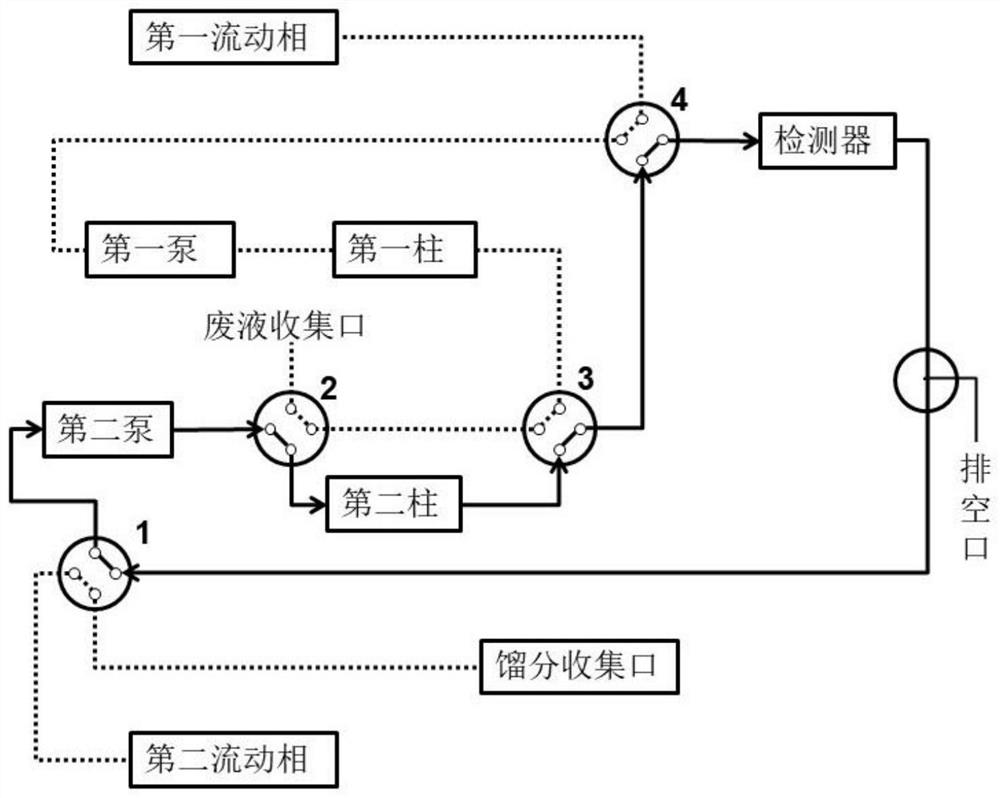

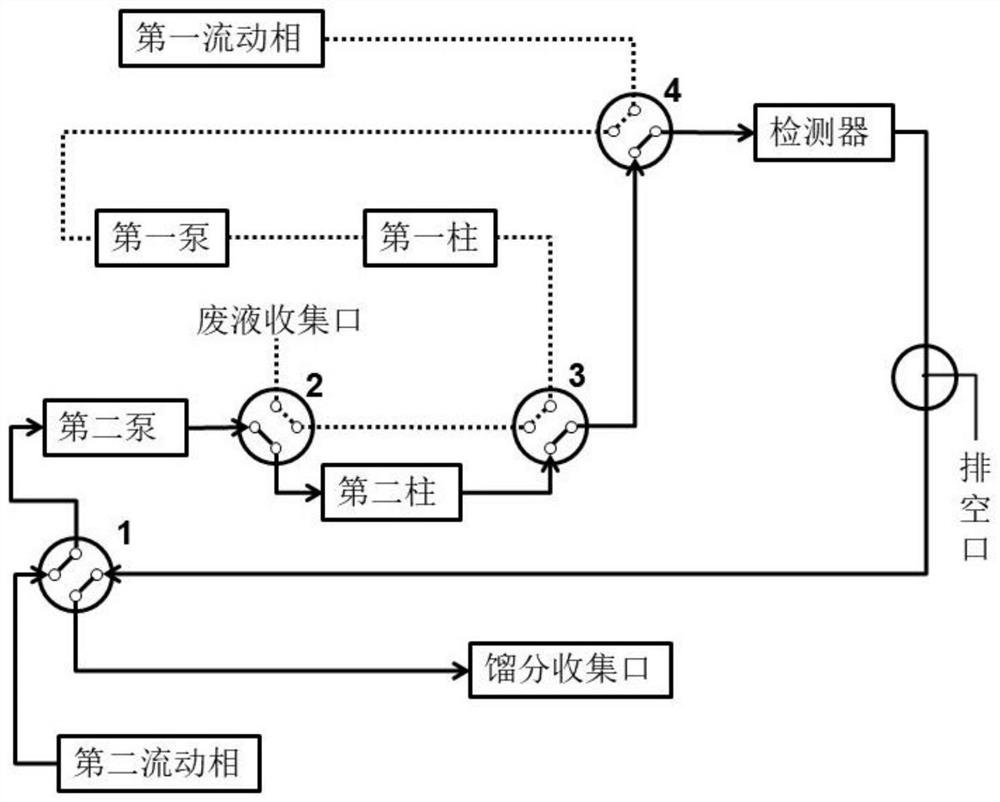

[0074] Separation and purification of gamma cyclodextrin: take gamma cyclodextrin and add methanol / water (v / v, 1 / 1) to prepare a solution with a concentration of 2 g / mL, and adjust the pH to 1-2 with 5% trifluoroacetic acid aqueous solution. After the solution was clarified, it was filtered through a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A self-assembled column is used, and the column packing model is SiliaSphere series ODS, with a particle size of 50 μm and a pore size of 0.1% trifluoroacetic acid aqueous solution was used as mobile phase A, methanol was used as mobile phase B, and the flow rate was 80 mL / min. Such as figure 1 As shown, the equilibration time of the first column and the second column is about 15min, and the crude product loading is carried out by the first pump ( figure 1 Marked by solid line), at 25min (that is, when the detector detects the target peak), switch valve 1, valve 2 and valve 3 sequentially...

Embodiment 2

[0076] Separation and purification of gamma cyclodextrin: take gamma cyclodextrin and add methanol / water (v / v, 1 / 1) to prepare a solution with a concentration of 2 g / mL, and adjust the pH to 1-2 with 5% trifluoroacetic acid aqueous solution. After the solution was clarified, it was filtered through a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A self-assembled column is used, and the column packing model is SiliaSphere series ODS, with a particle size of 50 μm and a pore size of 0.1% trifluoroacetic acid aqueous solution was used as mobile phase A, methanol was used as mobile phase B, and the flow rate was 80 mL / min. Such as figure 1 As shown, the equilibration time of the first column and the second column is about 15min, and the crude product loading is carried out by the first pump ( figure 1 Marked by the solid line), at 45min (the detector detects the target peak), switch valve 1, valve 2 and valve 3 sequentially and press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com