A kind of dendritic upy damping agent and its preparation method and application

A dendritic and damping agent technology, applied in the field of damping materials, can solve the problems of high temperature damping temperature range of chlorobutyl rubber, damping performance, heat resistance, mechanical properties and wear resistance that cannot meet actual needs, etc., and achieve excellent Damping performance, effect of wide high temperature damping temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

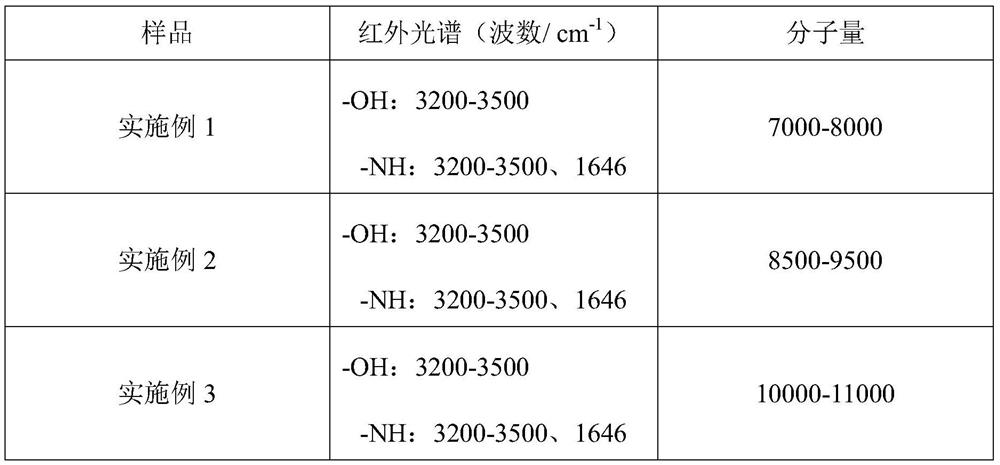

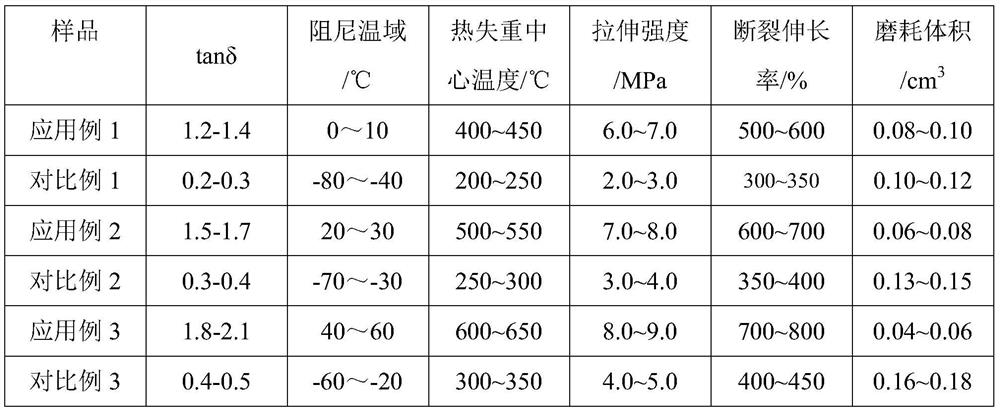

Examples

Embodiment 1

[0061] a) Preparation of dendrimers with terminal chlorine atoms:

[0062] Disperse 20g of hexachlorotripolyphosphazene and 0.1g of p-toluenesulfonic acid in 150g of ethylene glycol (ethylene glycol is used as reactant and solvent at the same time), then under nitrogen protection, stirring and reacting at 140 ° C for 2 hours, the end For the reaction, first vacuum was applied to remove unreacted monomers, then the residue was washed with methanol, centrifuged for precipitation, and the resulting precipitate was vacuum-dried at 40 °C for 6 hours to obtain the first generation dendrimer, abbreviated as D. -1;

[0063] Disperse 30g of 1,6-hexanediamine and 0.2g of p-toluenesulfonic acid in 100g of toluene, add D-1 prepared in the previous step, and then stir and react at 130°C for 4 hours under nitrogen protection, and complete the reaction, First vacuum was applied to remove unreacted monomers, then the residue was washed with methanol, centrifuged to precipitate, and the resul...

Embodiment 2

[0080] a) Preparation of dendrimers with terminal chlorine atoms:

[0081] Disperse 30g of hexachlorotripolyphosphazene and 0.2g of p-toluenesulfonic acid in 180g of ethylene glycol (ethylene glycol is used as reactant and solvent at the same time), then under nitrogen protection, stirring and reacting at 130 ° C for 3 hours, the end For the reaction, vacuum was first applied to remove unreacted monomers, then the residue was washed with methanol, centrifuged for precipitation, and the resulting precipitate was vacuum-dried at 50 °C for 5 hours to obtain the first generation dendrimer, abbreviated as D. -1;

[0082] Disperse 40g of 1,6-hexanediamine and 0.3g of p-toluenesulfonic acid in 130g of toluene, add D-1 prepared in the previous step, and then stir and react at 140 ° C for 3 hours under nitrogen protection, and complete the reaction, First vacuum was applied to remove unreacted monomers, then the residue was washed with methanol, the precipitate was centrifuged, and th...

Embodiment 3

[0099]a) Preparation of dendrimers with terminal chlorine atoms:

[0100] Disperse 40g of hexachlorotripolyphosphazene and 0.3g of p-toluenesulfonic acid in 210g of ethylene glycol (ethylene glycol is used as reactant and solvent at the same time), then under nitrogen protection, stirring and reacting at 120 ° C for 4 hours, the end Reaction, first vacuum to remove unreacted monomers, then the residue is washed with methanol, centrifuged to precipitate, and the obtained precipitate is vacuum-dried at 60 °C for 4 hours to obtain the first generation dendrimer, abbreviated as D -1;

[0101] Disperse 50g of 1,6-hexanediamine and 0.4g of p-toluenesulfonic acid in 150g of toluene, add D-1 prepared in the previous step, and then stir the reaction at 150 ° C for 2 hours under nitrogen protection, and complete the reaction, First vacuum was applied to remove unreacted monomers, then the residue was washed with methanol, the precipitate was centrifuged, and the resulting precipitate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com