Manufacturing method of unidirectional solvent-free polyurethane resin artificial leather

A solvent-free polyurethane and artificial leather technology, which is applied in textiles and papermaking, can solve the problems of unfavorable human health and the environment, complicated artificial leather methods, and uneconomical benefits, and achieves the goal of being suitable for large-scale promotion, enhancing mechanical properties, and manufacturing The effect of simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

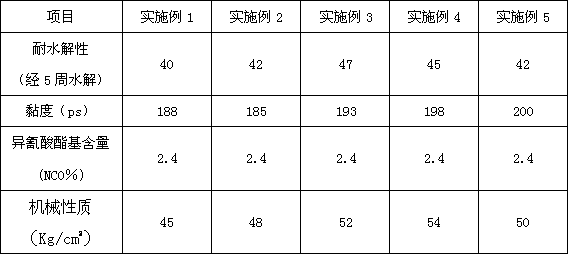

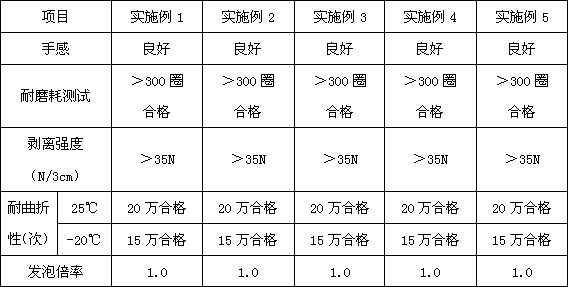

Examples

Embodiment 1

[0025] Mix unidirectional solvent-free polyurethane resin and leveling agent, heat to a molten state to obtain slurry; coat the slurry prepared in step S1 on the release layer, dry and solidify, and obtain a surface coated with a solvent-free polyurethane layer layer, the substrate layer is rolled and bonded to the surface layer coated with a solvent-free polyurethane layer, and then dried and cured to obtain artificial leather; wherein, the unidirectional solvent-free polyurethane resin consists of the following raw materials in parts by weight Prepared: 25 parts of polyether polyol with a functionality of 4 and a number average molecular weight of 4000, 4,4-dicyclohexane diisocyanate and 1,4-cyclohexane diisocyanate at a mass ratio of 3:1 65 parts of mixture, 5 parts of modified nanocrystalline cellulose, 5 parts of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, the preparation method is: polyether polyol , a mixture of 4,4-dicyclohexane diisocyanate and 1,4-cyclohexan...

Embodiment 2

[0028] Mix unidirectional solvent-free polyurethane resin and leveling agent, heat to a molten state to obtain slurry; coat the slurry prepared in step S1 on the release layer, dry and solidify, and obtain a surface coated with a solvent-free polyurethane layer layer, the substrate layer is rolled and bonded to the surface layer coated with a solvent-free polyurethane layer, and then dried and cured to obtain artificial leather; wherein, the unidirectional solvent-free polyurethane resin consists of the following raw materials in parts by weight Prepared: 30 parts of polyether polyol with a functionality of 5 and a number average molecular weight of 2000, 1-methyl-2,4-diisocyanatocyclohexane, 1-isocyanomethyl-3- 58 parts of a mixture of isocyano-1,5,5-trimethylcyclohexane and xylene diisocyanate, 8 parts of modified nanocrystalline cellulose (same as Example 1), N-ethylaminoisopropyl 4 parts of a mixture of phenyl trimethoxysilane, anilinopropyl trimethoxysilane and γ-ureaprop...

Embodiment 3

[0030] Mix unidirectional solvent-free polyurethane resin and leveling agent, heat to a molten state to obtain slurry; coat the slurry prepared in step S1 on the release layer, dry and solidify, and obtain a surface coated with a solvent-free polyurethane layer layer, the substrate layer is rolled and bonded to the surface layer coated with a solvent-free polyurethane layer, and then dried and cured to obtain artificial leather; wherein, the unidirectional solvent-free polyurethane resin consists of the following raw materials in parts by weight Prepared: 26 parts of polyether polyol with a functionality of 4 and a number average molecular weight of 6000, 1-isocyanomethyl-3-isocyano-1,5,5-trimethylcyclohexane and di 62 parts of a mixture of toluene diisocyanate, 8 parts of modified nanocrystalline cellulose (same as Example 1), 4 parts of a mixture of anilinopropyltrimethoxysilane and γ-ureapropyltrimethoxysilane, the preparation Method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com