A method for dyeing high-performance fiber in seconds with liquid film

A high-performance fiber and liquid film technology, which is applied in the field of textile printing and dyeing, can solve the problems of weak interface fastness, easy peeling off of color paste film, difficulty in dyeing bright colors of high-performance fabrics, etc., and achieve increased roughness and increased porosity. Effect

Active Publication Date: 2022-06-03

WUHAN TEXTILE UNIV

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The downside is that high temperature conditions can destroy the dye structure, thus making it difficult to dye bright colors on high performance fabrics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

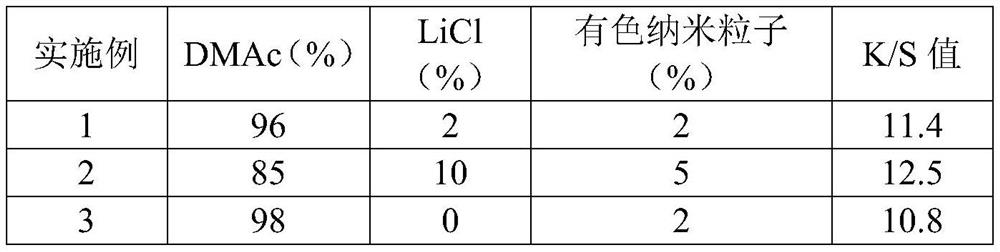

Embodiment 1

Embodiment 2-3

[0045]

Embodiment 4-10

[0049]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

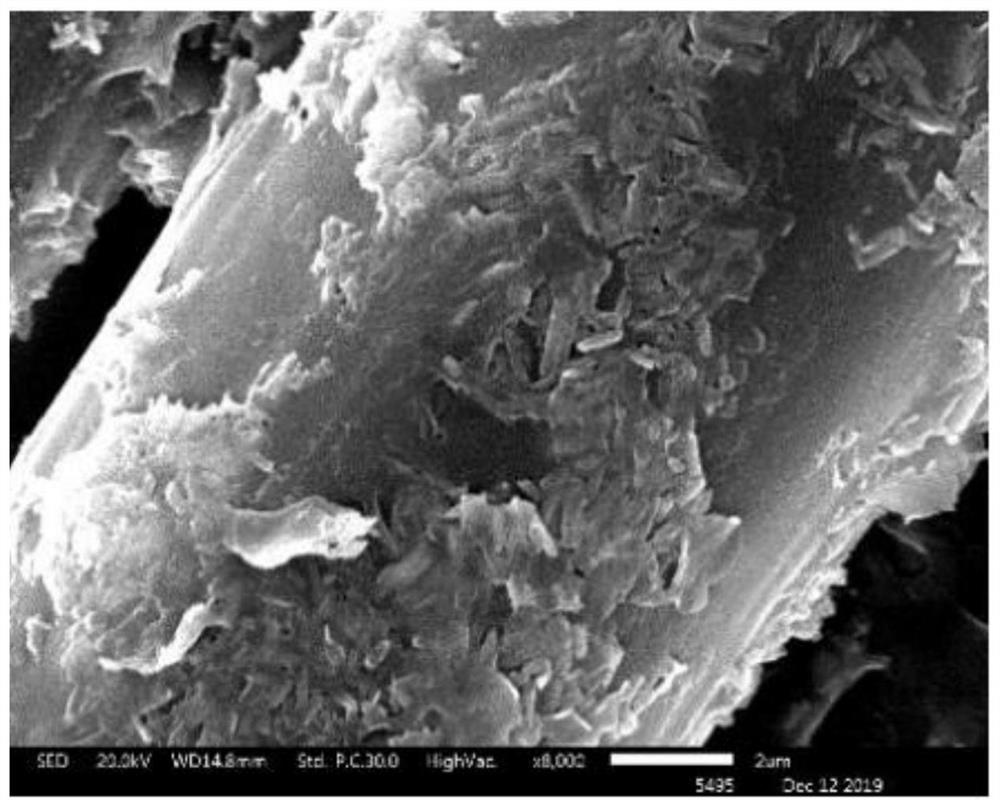

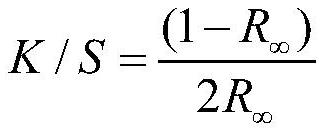

The invention discloses a method for quickly dyeing high-performance fibers with a liquid film. Firstly, the high-performance fibers are soaked in a dyeing solution composed of N,N-dimethylacetamide, LiCl and colored nanoparticles, and then the pre- The treated high-performance fibers are treated in a high-temperature oil bath. Through the small molecular structure of N,N-dimethylacetamide and the strong electronegativity of the amide carbonyl group, the surface roughness and pores of the high-performance fibers can be effectively improved. The rate increases, which is conducive to the adsorption of more colored particles. At the same time, the high-temperature and high-pressure steam in the oil bath dyeing process generates a certain internal and external pressure difference in the pores on the surface of the high-performance fiber, and cooperates with N,N-dimethylacetamide The interaction with LiCl makes the colored nanoparticles further absorbed into the inner layer of high-performance fibers to achieve rapid dyeing of high-performance fibers. The invention effectively improves the printing and dyeing efficiency and color fixation rate of the high-performance fiber, and is beneficial to expand the application of the high-performance fiber.

Description

A method of liquid film second dyeing high-performance fiber technical field [0001] The present invention relates to the technical field of textile printing and dyeing, in particular to a method for dyeing high-performance fibers in seconds with a liquid film. Background technique [0002] With the development of social economy, the application of high-performance fibers has become more and more extensive, due to its structure and performance The particularity of the fiber makes it have excellent properties that conventional fibers do not have, so it is widely used in aerospace, protection, military However, the poor dyeability of high-performance fibers has seriously affected its application development. Therefore, for high The improvement of dyeing properties of energy fibers is of great significance. Common high-performance fibers mainly include meta-aramid fibers, para-aramid fibers, polyimide fibers and polyarylate fiber, etc. So far, many scholars at home and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06P1/673D06P5/20D06P1/92D06P3/04D06P3/02D06P3/52

CPCD06P1/67358D06P5/2066D06P1/928D06P3/04D06P3/02D06P3/52D06P2001/906

Inventor 徐卫林夏良君盛丹付专周思婕张春华王运利

Owner WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com