Black cigarette paper and preparation method thereof

A cigarette paper, black technology, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of poor storage time stability, high cost of natural pigments, toxicity, etc., and achieve product safety, uniform and stable color, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

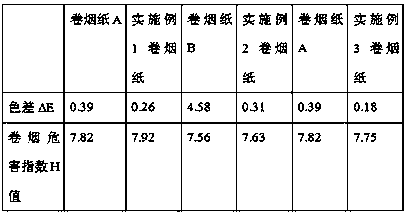

Examples

Embodiment 1

[0029] The black cigarette paper of the present embodiment comprises the following raw materials in parts by weight: 10 parts of food-grade carbon black pigment with a particle diameter of 10 to 19 nm, 20 parts of calcium carbonate filler, 5 parts of softwood pulp, 90 parts of hardwood pulp, and 0.05 parts of potassium oleate. 0.1 part of polyvinyl alcohol with a molecular weight of 200, and 1 part of other cigarette paper additives.

[0030] The preparation method of the black cigarette paper of the present embodiment is carried out as follows:

[0031] Add 0.05 part of potassium oleate and 0.1 part of polyvinyl alcohol with a molecular weight of 200 into 10 parts of water and stir evenly, then add 1 part of food-grade carbon black with a particle size of 10-19nm, homogenize by ultrasonic for 10 minutes, mix well, and age for 1 hour After causing no precipitation, the carbon black pigment solution is obtained.

[0032] Mix the carbon black pigment solution, calcium carbonate...

Embodiment 2

[0040] The black cigarette paper of the present embodiment comprises the following raw materials in parts by weight: 10 parts of food-grade carbon black pigment with a particle diameter of 400 to 500 nm, 20 parts of calcium carbonate filler, 30 parts of softwood pulp, 60 parts of hardwood pulp, and 0.1 parts of potassium oleate. 0.2 parts of polyvinyl alcohol with a molecular weight of 10,000, and 5 parts of other cigarette paper additives.

[0041] The preparation method of the black cigarette paper of the present embodiment is carried out as follows:

[0042] Stir 0.1 part of potassium oleate, 0.2 part of polyvinyl alcohol with a molecular weight of 10000 and 20 parts of water, and then add 10 parts of food grade carbon black pigment with a particle size of 400-500nm, homogenize with ultrasonic for 30 minutes, mix well, and age for 2 hours until After there is no precipitation, it is ready for use to obtain a carbon black pigment solution.

[0043] Mix the carbon black pigm...

Embodiment 3

[0049] The black cigarette paper of the present embodiment comprises the following raw materials in parts by weight: 5 parts of food-grade carbon black pigment with a particle diameter of 30 to 70 nm, 25 parts of calcium carbonate filler, 25 parts of softwood pulp, 70 parts of hardwood pulp, and 0.1 parts of potassium oleate. 0.2 parts of polyvinyl alcohol with a molecular weight of 2000, and 5 parts of other cigarette paper additives.

[0050] The preparation method of the black cigarette paper of the present embodiment is carried out as follows:

[0051] Stir 0.08 parts of potassium oleate, 0.15 parts of polyvinyl alcohol with a molecular weight of 10000, and 20 parts of water, and then add 2 parts of food-grade carbon black with a particle size of 30-70nm, homogenize with ultrasound for 25 minutes, mix well, and age for 1.5 hours After causing no precipitation, the carbon black pigment solution is obtained.

[0052] Mix the carbon black pigment solution, calcium carbonate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com