Device and method for in-situ rapid testing of coal seam permeability by portable through-bed drilling

A piercing drilling, portable technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of affecting the evaluation of coal seam gas drainage effect, ignoring the dynamic evolution process of cracks, destroying coal Consider the objective environment and other problems, and achieve the effects of high measurement effect, ingenious structural design, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

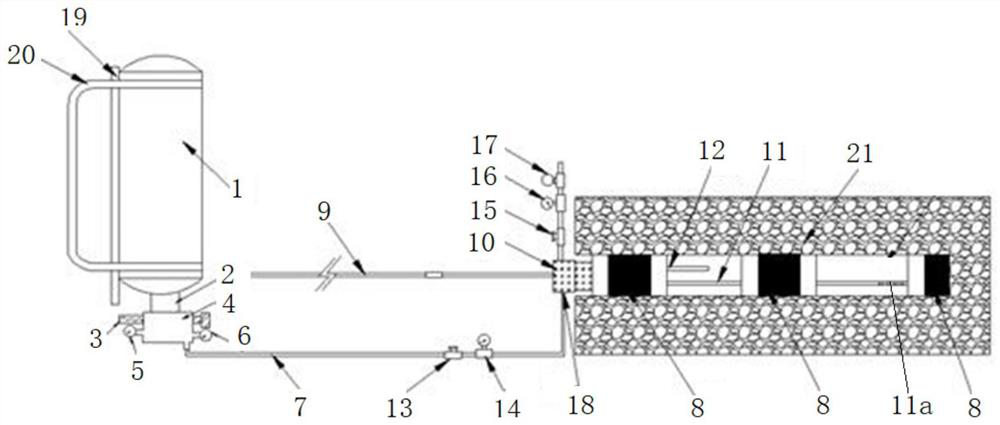

[0052] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0053] A portable device for quickly testing the permeability of coal seams in situ through bed drilling, such as figure 1 As shown, it mainly consists of mobile strap type gas cylinder 1, explosion-proof gas cylinder valve 2, safety valve 3, pressure reducer 4, high pressure gauge 5, low pressure gauge 6, high pressure hose 7, packer 8, push rod 9 , push block 10, gas injection pipe 11, measuring tube 12, first shut-off valve 13, first gas pressure gauge 14, second shut-off valve 15, second gas pressure gauge 16, second gas flow meter 17, high-pressure joint 18, Shoulder strap 19 and braces 20 form.

[0054] The mobile strap-type gas cylinder 1 is equipped with an explosion-proof gas cylinder valve 2, a safety valve 3, a pressure reducer 4, a high-pressure pressure gauge 5, and a low-pressure pressure gauge 6, so as to ensure easy portability, safety an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com