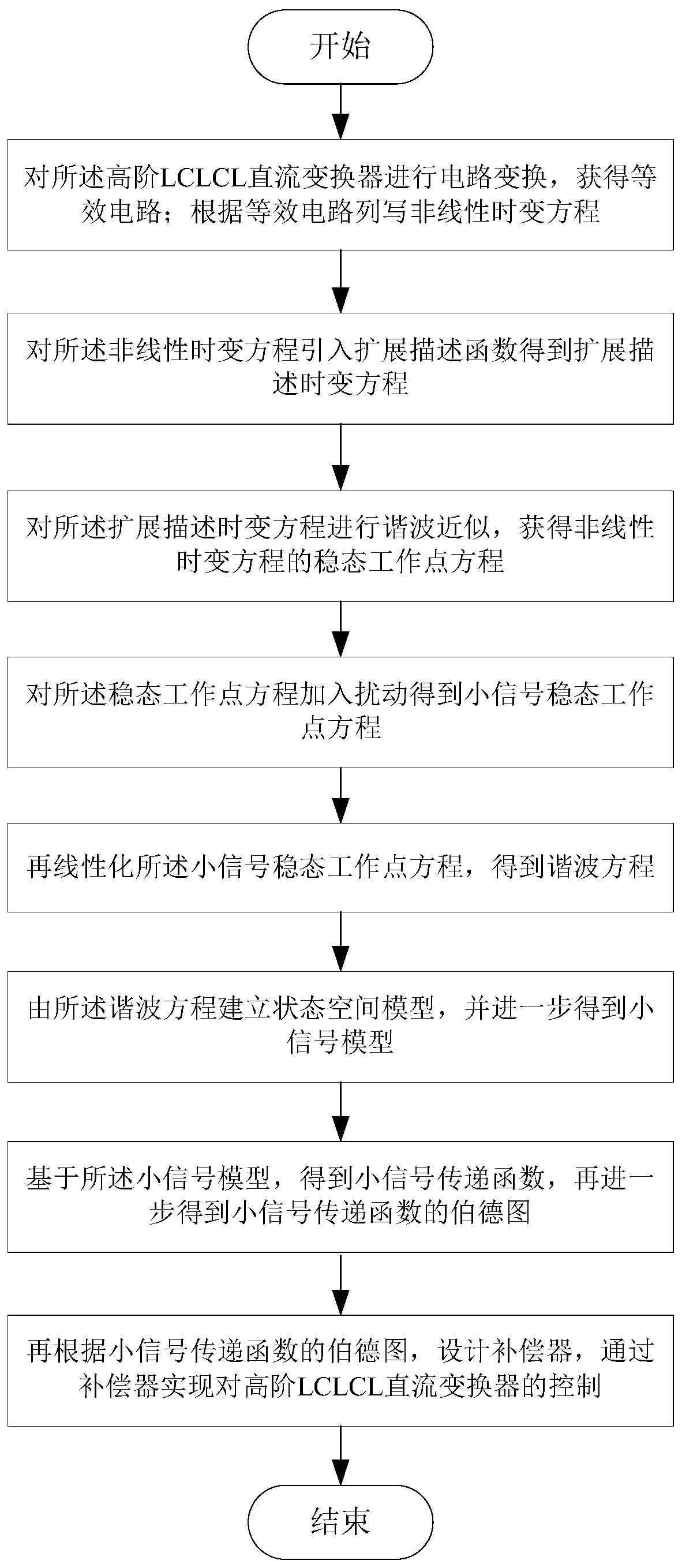

Control method of high-order LCLCL direct-current converter

A technology of a DC converter and a control method, which is applied in the conversion of DC power input to DC power output, control/regulation systems, high-efficiency power electronic conversion, etc., can solve the problem that power converters are not suitable for LCLCL high-order systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

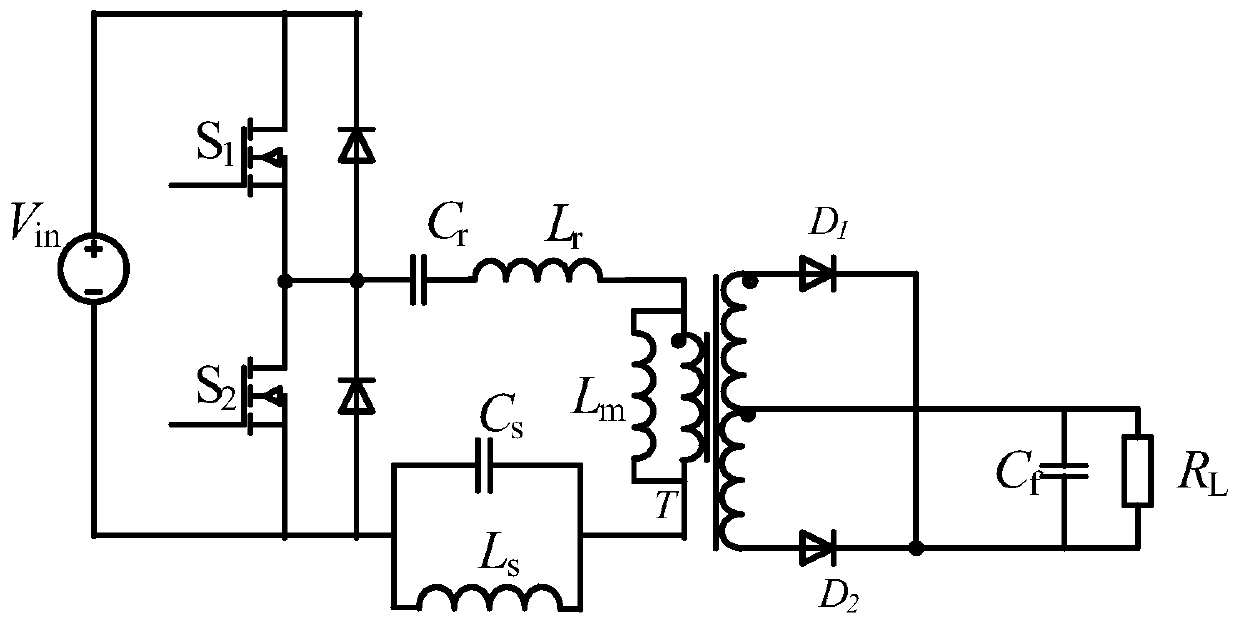

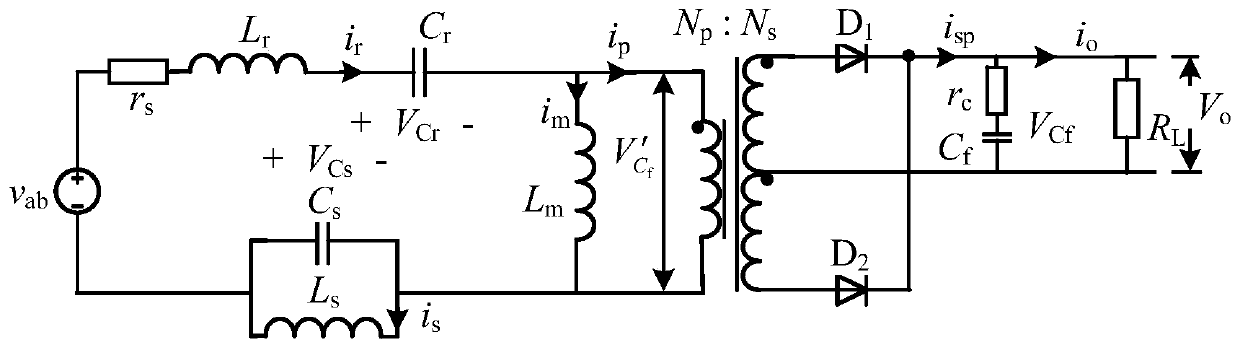

[0037] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a control method of a high-order LCLCL DC converter, and the high-order LCLCL DC converter includes a switching tube S 1 , switch tube S 2 , Resonant capacitance C r , Resonant inductance L r , transformer T, band stop filter inductor L s , Band stop filter capacitor C s , Diode D 1 , Diode D 2 and output capacitor C f ,

[0038] Band stop filter inductor L s and bandstop filter capacitor C s are connected in parallel to form a band-stop filter;

[0039] Switch tube S 1 The drain is connected to the power supply V in positive pole of the switch tube S 1 The source is connected to the switch S 2 The drain of the switch tube S 2 The source is connected to the power supply V in The negative pole of the resonant capacitor C r , Resonant inductance L r , the primary side of the transformer T and the band-stop filter are connected in series in the switch tube S 2 b...

specific Embodiment

[0168] In order to verify the feasibility of selecting the topology and parameter design of the present invention, a prototype with the following indicators was built

[0169] Rated input voltage: 400V;

[0170] Rated power: 400W;

[0171] Series resonant frequency: 1MHz (fundamental wave), 3MHz (third harmonic);

[0172] Parallel resonance frequency: 2MHz;

[0173] Efficiency: higher than 95%;

[0174] Output voltage: 24V;

[0175] Output voltage ripple: less than 200mV;

[0176] The chip type and parameters of the DC converter selected by the prototype are shown in Table 1.

[0177] Table 1

[0178]

[0179] According to the parameters in the above table, the resonance parameters, load parameters, and parasitic parameters are substituted into the model, and the following can be obtained: Figure 5 The transfer function of the pole-zero distribution shown.

[0180] Going one step further, the bode image before compensation is obtained as shown in Figure 6 shown; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com