Method for separating and purifying total flavonoids and total saponins from fibrous roots of ophiopogon japonicus and simultaneously removing paclobutrazol

A technology for separation and purification of total flavonoids, applied in the field of separation and purification of total saponins and total flavonoids, can solve the problems of complex operation process, low recovery rate, large loss, etc., and achieve the effect of simple process flow, less loss and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

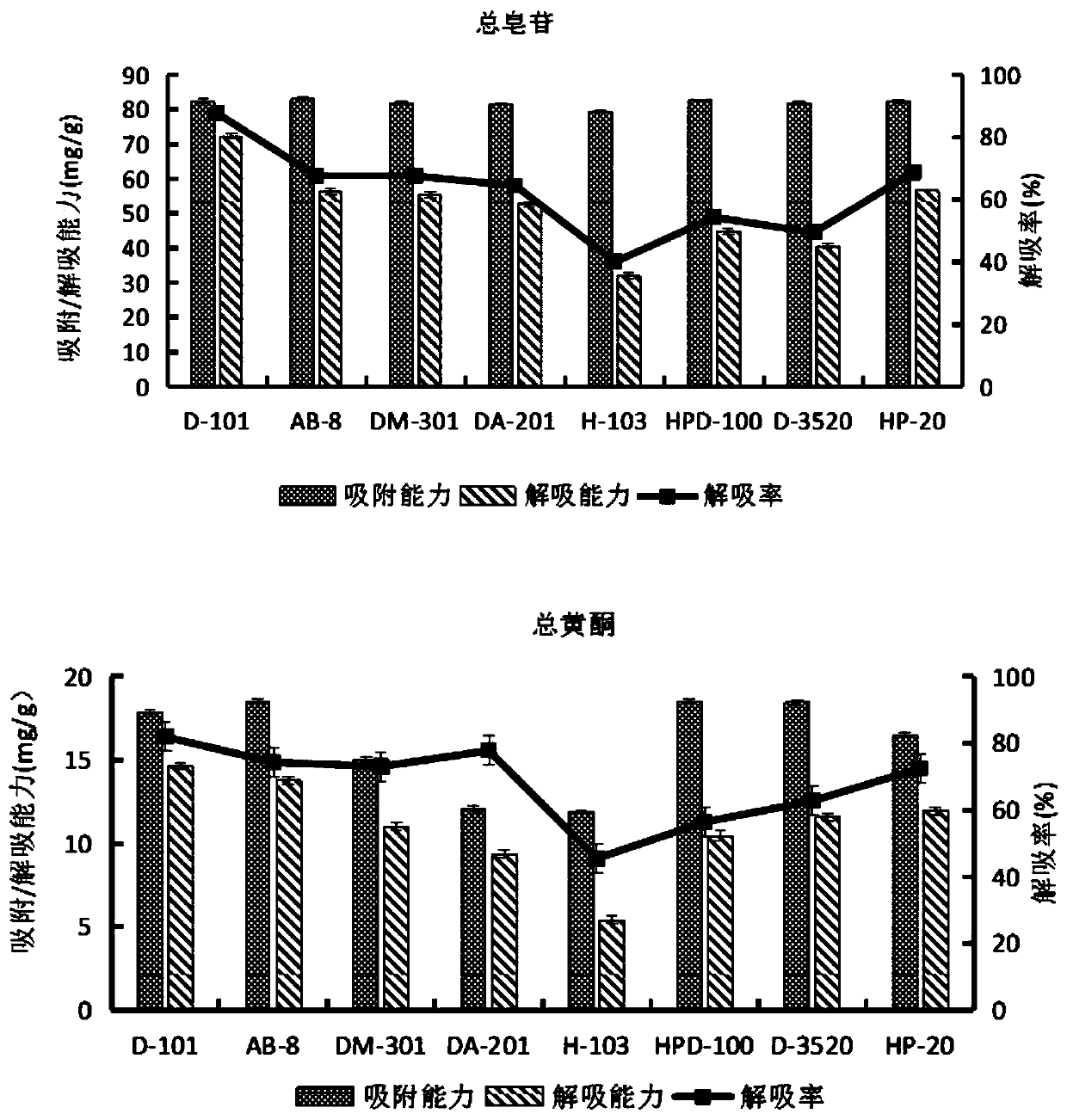

[0050] Resin screening: Take an appropriate amount of the extract, dissolve it with water, weigh each resin (equivalent to 0.1g dry weight) into an Erlenmeyer flask, add 30mL sample solution, and shake it in a constant temperature shaker at 25°C and 150r / min for 24h. Suction filtration, determine the content of saponins and flavonoids in the remaining adsorption solution, and calculate the adsorption rate; then add 30mL of 95% ethanol to each conical flask, shake in a constant temperature shaker at 25°C, 150r / min for 12h, and filter with suction to determine the saponin in the desorption solution , Flavonoid content, calculate the desorption rate; the calculation result is as figure 1 Shown, according to figure 1 The displayed results show that: D101 macroporous resin is the most preferred resin.

Embodiment 2

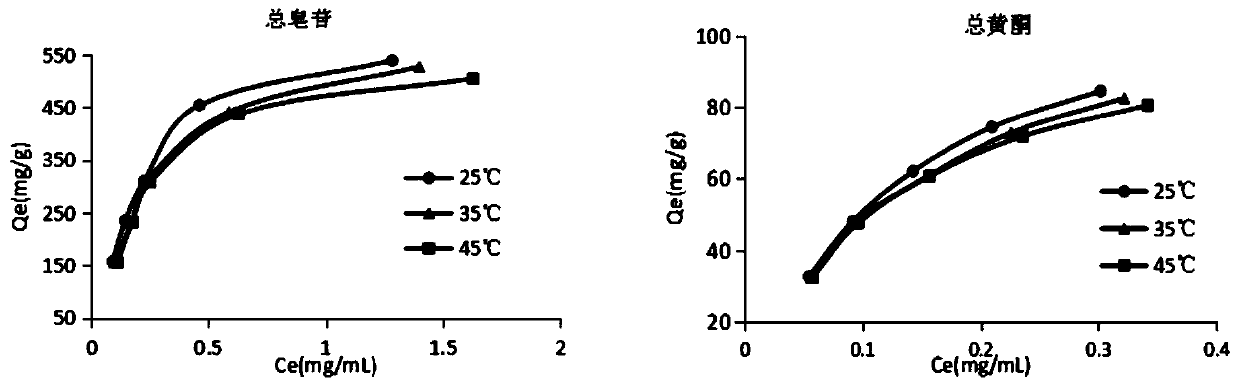

[0052] Determine the most preferred adsorption temperature: Take 5 portions of the best resin that has been processed, equivalent to 2g of dry weight) Place them in a 500mL Erlenmeyer flask, add 200mL of sample solution, and perform static adsorption at 25℃, 35℃, and 45℃ , Calculate its adsorption rate and judge the influence of temperature on static adsorption, such as Figure 2-4 And shown in Table 1.

[0053] among them figure 2 It is the adsorption isotherm of D101 macroporous resin to the total saponins and total flavonoids in Ophiopogon japonicus fibrous roots under different temperature conditions. According to the results shown in the curve, the adsorption capacity is highest when the adsorption temperature is 25℃, and the lowest at 45℃, indicating that low temperature is beneficial to adsorption .

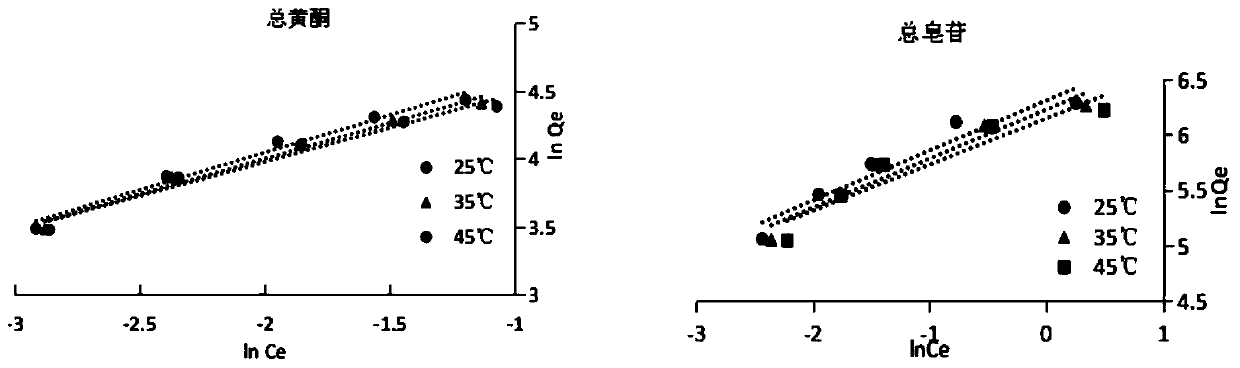

[0054] among them image 3 Fitting curve diagram for Langmuir isotherm adsorption equation, Figure 4 Fitting curve diagram for Freundlich isotherm adsorption equation, Langmu...

Embodiment 3

[0060] Study the effect of solution concentration, sample flow rate, sample pH on dynamic adsorption, such as Figure 5-7 As shown, take 5 parts each of the best type of resin that has been screened (equivalent to 8g dry weight), and pack them into the column; prepare sample solutions of Ophiopogon japonicus fibrous roots with different concentrations, and the column flow rate requirement is 2mL / min. Add total flavonoids and The sample solution of Ophiopogon japonicus fibrous root with a total saponin concentration of (0.198, 1.48 mg / mL; 0.396, 2.96 mg / mL; 0.594, 4.44 mg / mL; 0.792, 5.92 mg / mL; 0.99, 7.44 mg / mL) was used for dynamic adsorption experiments , Collect, measure the absorbance, calculate the adsorption rate, such as Figure 5 As shown; take 5 pretreated best type of resin (equivalent to 8g dry weight), packed into a column, each add the total flavonoids and total saponin concentration (0.198, 1.48mg / mL) Ophiopogon japonicus root sample solution; Adsorb at the speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com