Method for preparing carbon sequestration biochar by using mixed sludge

A technology of mixing sludge and biochar, applied in sludge treatment, pyrolysis sludge treatment, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

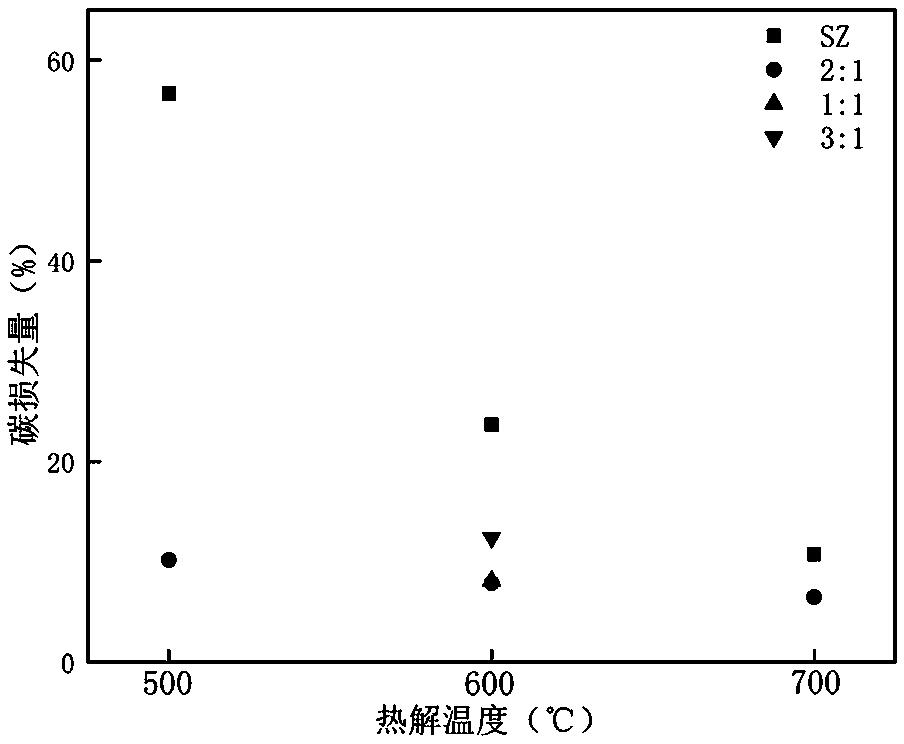

Embodiment 1

[0012] (1) Dry and dehydrate municipal sludge biochar. Weigh a certain amount of dry sludge and put it in a pulverizer until it is crushed into powder.

[0013] (2) Put the sludge powder in the step (1) into the defense crucible, then place it in the muffle furnace, feed nitrogen at a rate of 220ml / min, run the muffle furnace after the air in the muffle furnace is exhausted, and set the temperature to rise The rate is 10°C / min, take the room temperature as 20°C, raise the temperature for 8.5 minutes to reach t1=105°C, maintain for 3 hours, reach t2=105°C, then raise the temperature for 49.5 minutes, reach the set temperature t3=600°C, and maintain for 4 hours.

[0014] (3) After the pyrolysis is completed, put it in a desiccator to cool naturally, and pass through a 50-mesh sieve to obtain mixed sludge biochar.

Embodiment 2

[0016] (1) Dry and dehydrate the municipal sludge and pharmaceutical factory sludge separately. According to the mass ratio of 1:1, take the municipal sludge and the pharmaceutical factory sludge and put them in the pulverizer, and grind them into powder.

[0017] (2) Put the powdery mixed sludge in the crucible, then place it in the muffle furnace, feed nitrogen gas at a rate of 220ml / min, run the muffle furnace after the air in the muffle furnace is exhausted, and set the heating rate to 10°C / min, take the room temperature as 20°C, raise the temperature for 8.5min to t1=105°C, maintain for 3h, reach t2=105°C, then raise the temperature for 49.5min, reach the set temperature t3=600°C, and maintain for 4h.

[0018] (3) After the pyrolysis is completed, put it in a desiccator to cool naturally, and pass through a 50-mesh sieve to obtain mixed sludge biochar.

Embodiment 3

[0020] (1) Dry and dehydrate the municipal sludge and pharmaceutical factory sludge separately. According to the mass ratio of 2:1, the municipal sludge and pharmaceutical factory sludge are put into a pulverizer and ground into powder.

[0021] (2) Put the powdery mixed sludge in the crucible, then place it in the muffle furnace, feed nitrogen gas at a rate of 220ml / min, run the muffle furnace after the air in the muffle furnace is exhausted, and set the heating rate to 10°C / min, take the room temperature as 20°C, raise the temperature for 8.5min to t1=105°C, maintain for 3h, reach t2=105°C, then raise the temperature for 49.5min, reach the set temperature t3=600°C, and maintain for 4h.

[0022] (3) After the pyrolysis is completed, put it in a desiccator to cool naturally, and pass through a 50-mesh sieve to obtain mixed sludge biochar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com