Catalyst and its preparation method and application and preparation method of 1,3-butadiene

A catalyst and solvent technology, which is applied in the field of catalyst and its preparation method and application, and the preparation of 1,3-butadiene, can solve the problems such as high requirement of raw material ethanol concentration, low catalyst selectivity, catalyst carbon deposition and deactivation, etc. , to achieve the effects of excellent catalytic performance, good hydrothermal stability, and strong carbon capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to the present invention, preferably, in order to further improve the catalytic activity and selectivity of the catalyst, the preparation method of the catalyst comprises: converting the molecular sieve with EWT structure into H-EWT molecular sieve, and preparing the H-EWT molecular sieve with skeleton vacancies , and the H-EWT molecular sieves with framework vacancies were dispersed in a solution containing metal oxide precursors, then the solvent was removed and calcined. By preparing the H-EWT molecular sieve with skeleton vacancies, highly dispersed metal oxides are connected to the molecular sieve skeleton, thereby further improving the catalytic activity and selectivity of the catalyst.

[0034] Wherein, the method for converting the molecular sieve with EWT structure into H-EWT molecular sieve can be carried out with reference to conventional methods in the art. For example: ammonium salt exchange and deamination roasting of molecular sieves (including ...

preparation example 1

[0062] Add 0.268g of sodium metaaluminate into a 45mL polytetrafluoroethylene container, and add 15.5g of an aqueous solution of template agent R (1,5-bis(N-propylpyrrolidinium)pentane dihydroxide) (of R content is 30% by mass), stirred for 30 minutes until uniform, then added 6g of solid silica gel (SiO 2 content is 98.05% by mass) and 17.5g deionized water, stirred for 5 minutes and fully mixed, wherein the molar ratio of each component is: SiO 2 / Al 2 o 3 =60,H 2 O / SiO 2 =10, Template R / SiO 2 =0.16, OH - / SiO 2 = 0.32.

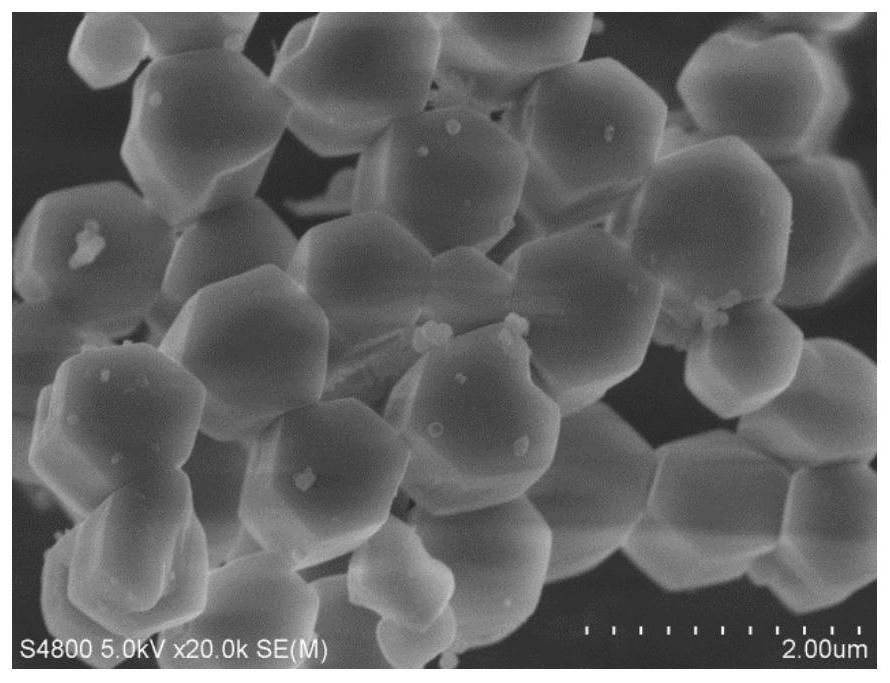

[0063] The above mixture was put into a 45mL polytetrafluoroethylene-lined steel autoclave, covered and sealed, and the autoclave was placed in a rotating convection oven with the rotation speed set at 20rpm, and reacted at 150°C for 5 days. Take out the autoclave and let it cool down to room temperature quickly, separate the mixture on a 5000rpm high-speed centrifuge, collect the solid, wash it thoroughly with deionized water, and dry it at 100°C f...

preparation example 2

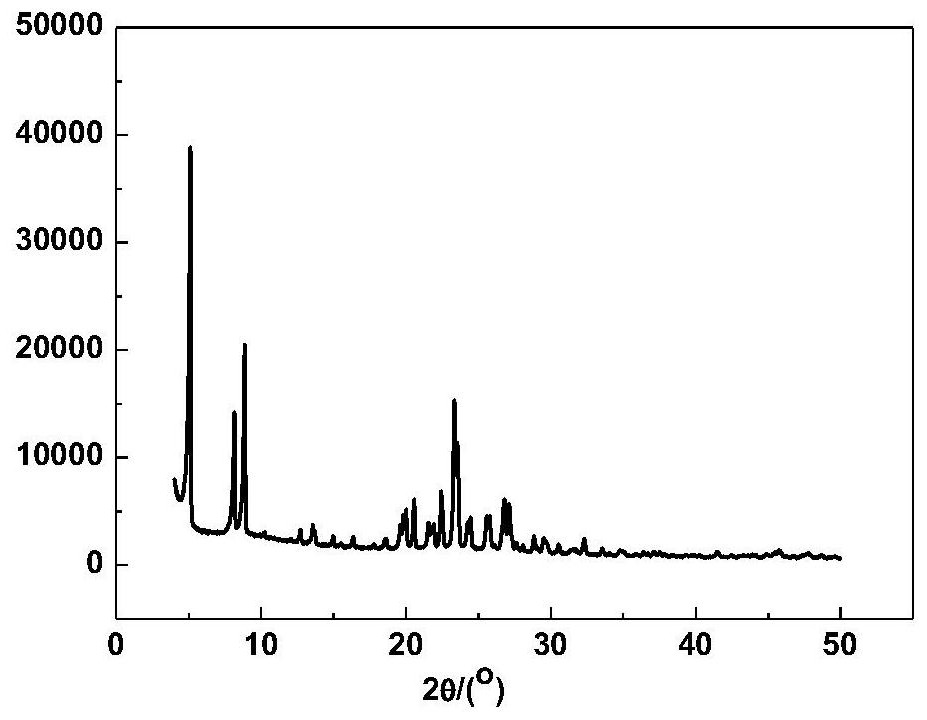

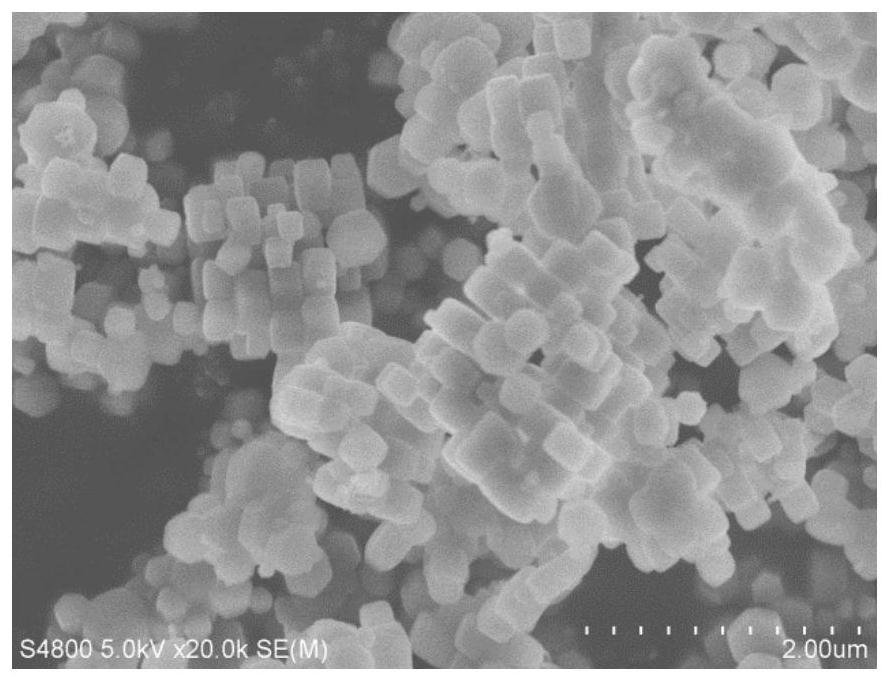

[0065] Prepare the original powder of EWT structural molecular sieve according to the method of Preparation Example 1. The difference is that the amount of sodium metaaluminate is 0.107g, and the types and amounts of other materials are the same as in Preparation Example 1, wherein the molar ratio of each component is: SiO 2 / Al 2 o 3 =120,H 2 O / SiO 2 =10, Template R / SiO 2 =0.16, OH - / SiO 2 = 0.32. Finally, the raw powder of molecular sieve with EWT structure is obtained. The scanning electron microscope image of the product is shown in image 3 As shown, the XRD pattern is as Figure 4 As shown, the silicon-aluminum ratio of the original powder sample obtained by X-ray fluorescence spectroscopic analysis is 98. The total specific surface of the molecular sieve with the EWT structure is S 总 =601m 2 / g, the total pore volume is V 总 =0.386cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com