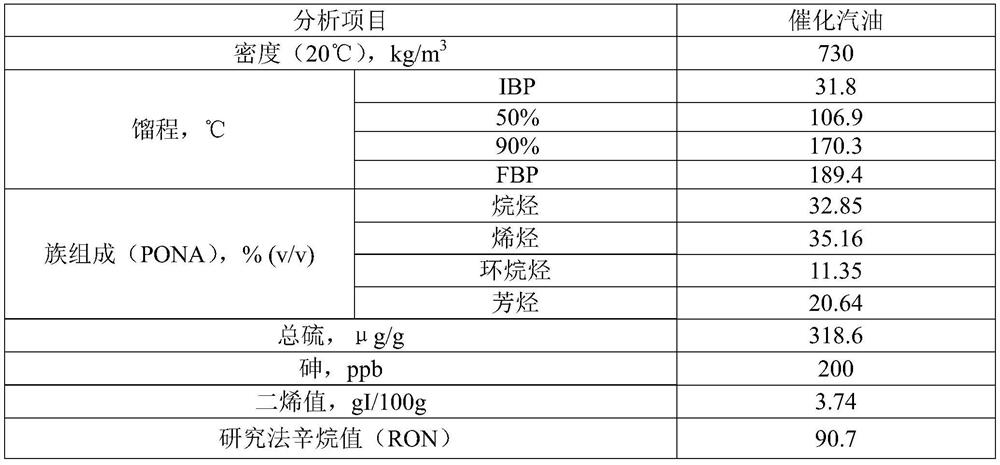

A catalytic gasoline hydrogenation dearsenic agent and its preparation method and application

A technology for catalyzing gasoline and arsenic removal agent, which is applied in chemical instruments and methods, refining hydrocarbon oil, treating hydrocarbon oil, etc., and can solve the problems of blocked pores, oxide content, arsenic removal activity and selectivity, and octane number loss, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of catalytic gasoline hydrogenation dearsenic agent, comprising the following steps:

[0040] Step 1: Mix alumina or a mixture of alumina and titanium oxide with scallop powder evenly, add organic polymer pore-forming agent, binder and deionized water, knead, extrude, and dry at 100-150°C for 3-6 hours , heat treatment at 650-1000°C for 3-6 hours at high temperature to prepare arsenic-removing agent carrier;

[0041] Step 2: The arsenic removal agent carrier is subjected to hydrothermal treatment to expand the pores, the treatment temperature is 400-700°C, and the mass space velocity is 0.5-1.5h -1 , treated for 1-10 hours to obtain arsenic-removing agent-modified carrier;

[0042] Step 3, dissolving the active component nickel salt in one or more of citric acid, ammonia water and deionized water to form a stable active metal complex solution, and then impregnating the arsenic removal agent with an equal volume of the active metal complex solution ...

Embodiment 1

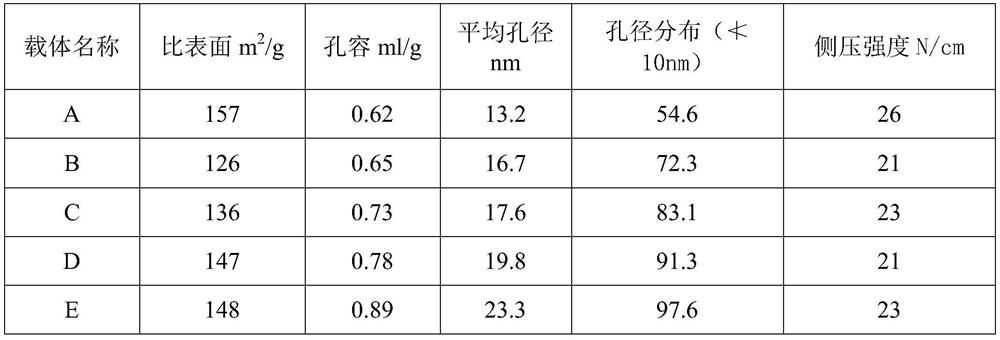

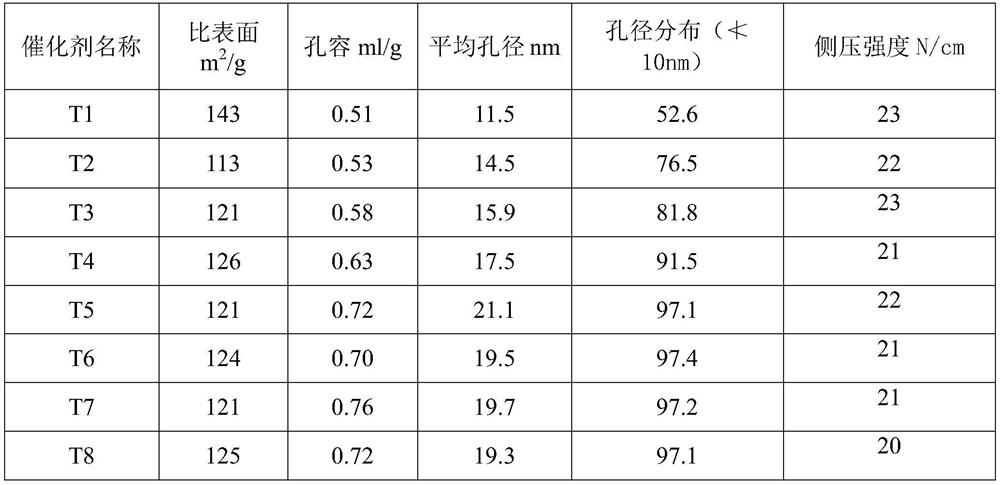

[0049] Weigh 100g of pseudo-boehmite, add 3.0g of fenugreek powder, and then add 3% nitric acid aqueous solution, knead and extrude, dry at 120°C for 4h, and then roast at 750°C for 4h to obtain arsenic removal agent carrier A (see Table 1 for properties). Weigh 20.0g of the carrier and put it into a beaker, add excess deionized water and let it stand for 3 hours, then remove the excess water on the surface of the carrier, compare the weight w1 of the carrier before immersion and the weight w2 of the carrier after immersion to calculate its water absorption, and then follow the equal volume immersion method , according to the water absorption of the carrier, the preparation of the active component impregnation solution is carried out. First weigh 60ml of deionized water, then add 42g of nickel nitrate and stir until dissolved, and finally use deionized water to make up the volume. The carrier was impregnated by an equal volume impregnation method, so that the catalyst carrier...

Embodiment 2

[0051] Weigh out 5% TiO 2 Add 100g of pseudo-boehmite to 100g of pseudo-boehmite, add 3.0g of fenugreek powder, 5g of organic polymer pore-forming agent polyvinyl alcohol with a particle size of 200μm, and then add 3% aqueous nitric acid solution, knead, extrude, and dry at 120°C for 4h , and then roasted at 750°C for 4h, then hydrothermally treated, the treatment conditions are: reaction temperature 600°C, mass space velocity 0.5h -1 , 4h, prepared modified carrier B (properties are shown in Table 1). The impregnation method of the metal active component, the impregnation amount of the nickel salt, and the drying and roasting conditions were the same as in Example 1, and the arsenic removal agent sample T2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com