Deamination tower system and deamination method for recovering TVR condensed water

A technology of deamination tower and condensate water, which is applied in separation methods, distillation energy recovery, chemical instruments and methods, etc., can solve the problems of low energy utilization rate and operation limitations, and achieve the effect of improving steam utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

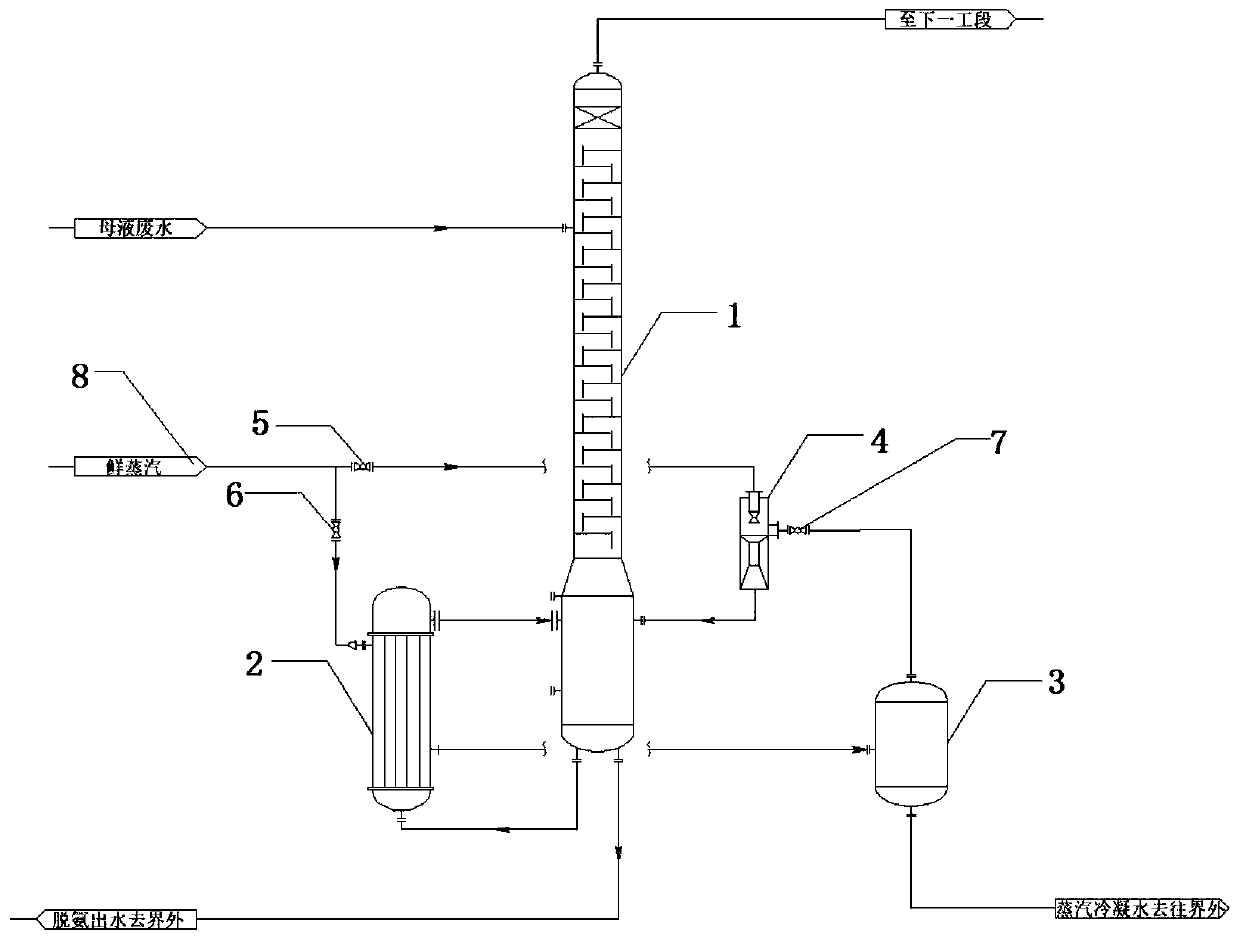

[0023] Such as figure 1 As shown, this embodiment provides a deammonization tower system for TVR condensate recovery, including a rectification tower 1, a reboiler 2, a flash tank 3, a jet heat pump 4 and a fresh steam pipeline 8; the rectification tower 1 The pipeline of the tower kettle is connected with a reboiler 2, the condensed water outlet of the shell side of the reboiler 2 is connected with the pipeline of the flash tank 3, and the fresh steam inlet of the shell side is connected with the first branch of the fresh steam pipeline 8; The steam outlet at the top of the steamer 3 is connected to the low-pressure steam inlet pipeline of the jet heat pump 4, the high-pressure steam inlet of the jet heat pump 4 is connected to the second branch of the fresh steam pipeline 8, and the medium-pressure steam outlet of the jet heat pump 4 It is connected with the still pipe of rectification tower 1; a first valve 6 is set on the first branch, and a second valve 5 is set on the se...

Embodiment 2

[0027] This embodiment provides the deammonization tower system adopting the TVR condensed water recovery of the above embodiment 1, and the deammonization method for ternary waste water:

[0028] Including tower kettle reboiler type and stripping type:

[0029] The tower kettle reboiler type includes the following steps: close the second valve 5 and the third valve 7, open the first valve 6; the preheated ternary mother liquor enters the rectification section of the rectification tower 1, and the 0.5-0.6Mpa The fresh steam enters the shell side of the reboiler 2 for energy supply, and the fresh steam turns into condensed water after heat exchange in the reboiler 2, and the condensed water enters the flash tank 3 for standby; Enter the follow-up section for the next step of zero-emission treatment; the material at the top of the rectification tower 1 is processed in the next section, and the product extracted from the top of the tower is recovered.

[0030] The air lift type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com