Efficient cleaning and etching composite assembly line for stainless steel machining

An assembly line and stainless steel technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of multiple cleaning and chemical etching processes, low production efficiency, and multiple assembly lines, so as to save manpower and material resources and improve automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

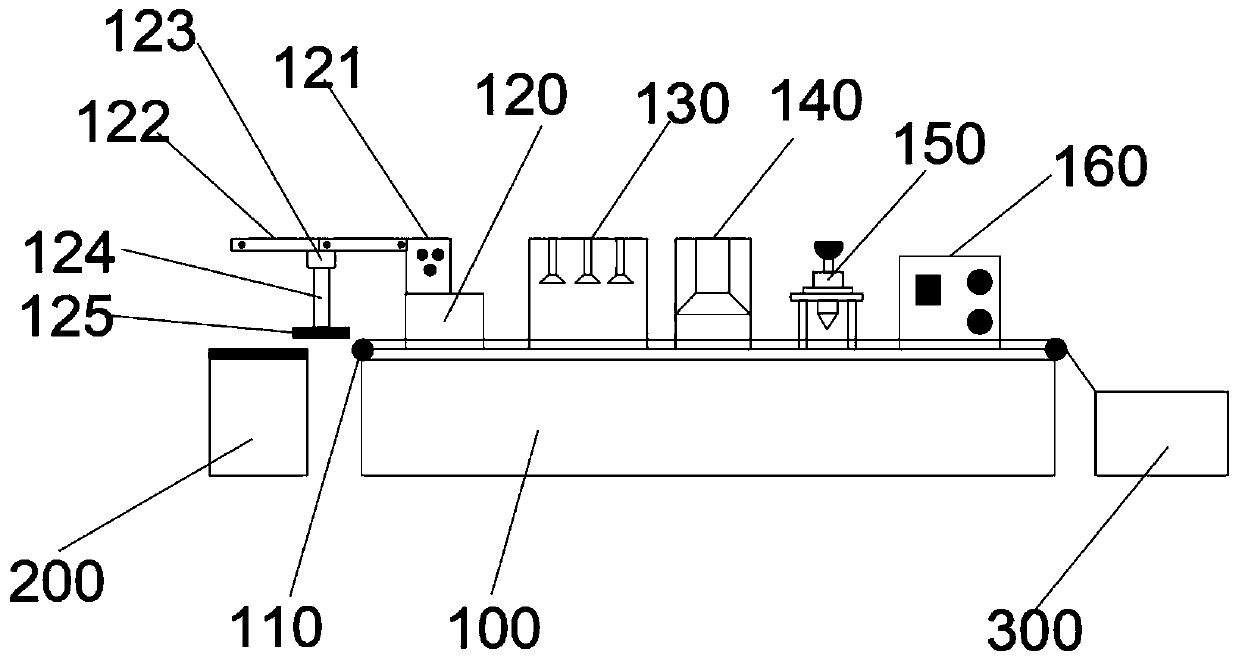

[0022] Such as figure 1 Shown is an efficient cleaning and etching composite assembly line for stainless steel processing, including an assembly line base 100, a conveyor belt 110, a delivery robot 120, a cleaning module 130, a drying module 140, a laser etching module 150, a polishing module 160, a feeding table 200, an output material platform 300; the transfer robot 120 includes a control base 121, a beam 122, a slider 123, a telescopic arm 124, and an electromagnetic chuck 125; the conveyor belt 110 is arranged on the assembly line base 100, and the transfer robot 120 is located on the On the side of the beginning of the conveyor belt 110, the cleaning module 130 is arranged on the assembly line base 100 and across both sides of the conveyor belt 110; the drying module 140 is arranged behind the cleaning module 130 and across Across both sides of the conveyor belt 110; the laser etching module 150 is arranged after the drying module 140 and across both sides of the conveyo...

Embodiment 2

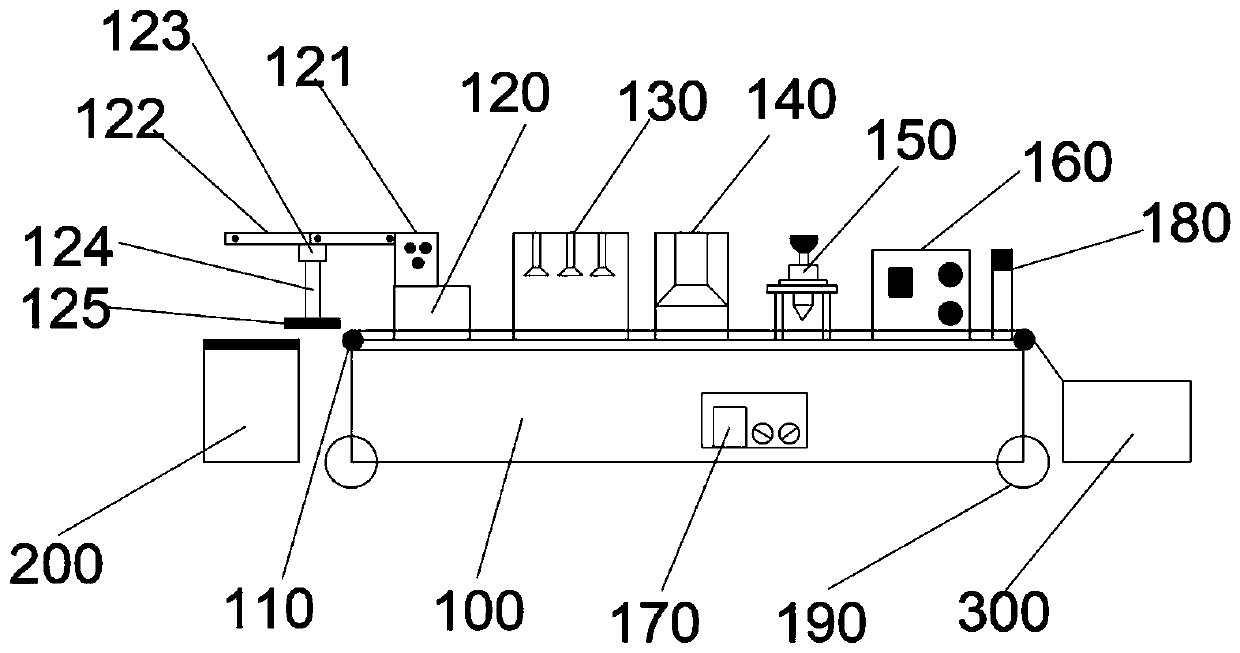

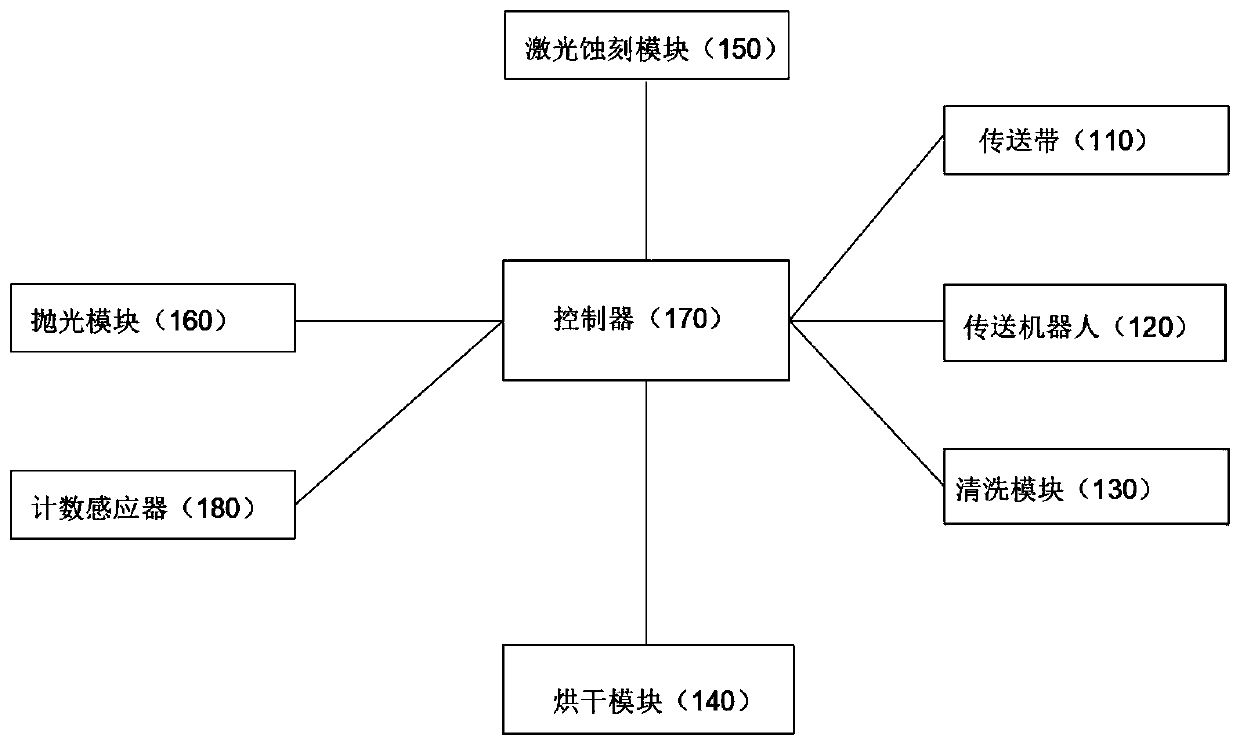

[0025] Such as figure 2 and 3 Shown is an efficient cleaning and etching composite assembly line for stainless steel processing, including an assembly line base 100, a conveyor belt 110, a delivery robot 120, a cleaning module 130, a drying module 140, a laser etching module 150, a polishing module 160, a feeding table 200, an output material platform 300; the transfer robot 120 includes a control base 121, a beam 122, a slider 123, a telescopic arm 124, and an electromagnetic chuck 125; the conveyor belt 110 is arranged on the assembly line base 100, and the transfer robot 120 is located on the On the side of the beginning of the conveyor belt 110, the cleaning module 130 is arranged on the assembly line base 100 and across both sides of the conveyor belt 110; the drying module 140 is arranged behind the cleaning module 130 and across Across both sides of the conveyor belt 110; the laser etching module 150 is arranged after the drying module 140 and across both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com