Multi-stage grinding machine for mechanical equipment production

A technology of mechanical equipment and grinding machines, which is applied in the direction of grinding machine tools, metal processing equipment, and parts of grinding machine tools. It can solve the problems of inconvenient grinding of workpieces and easy mutual influence, and achieves easy maintenance and replacement, large transmission ratio, and stable transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

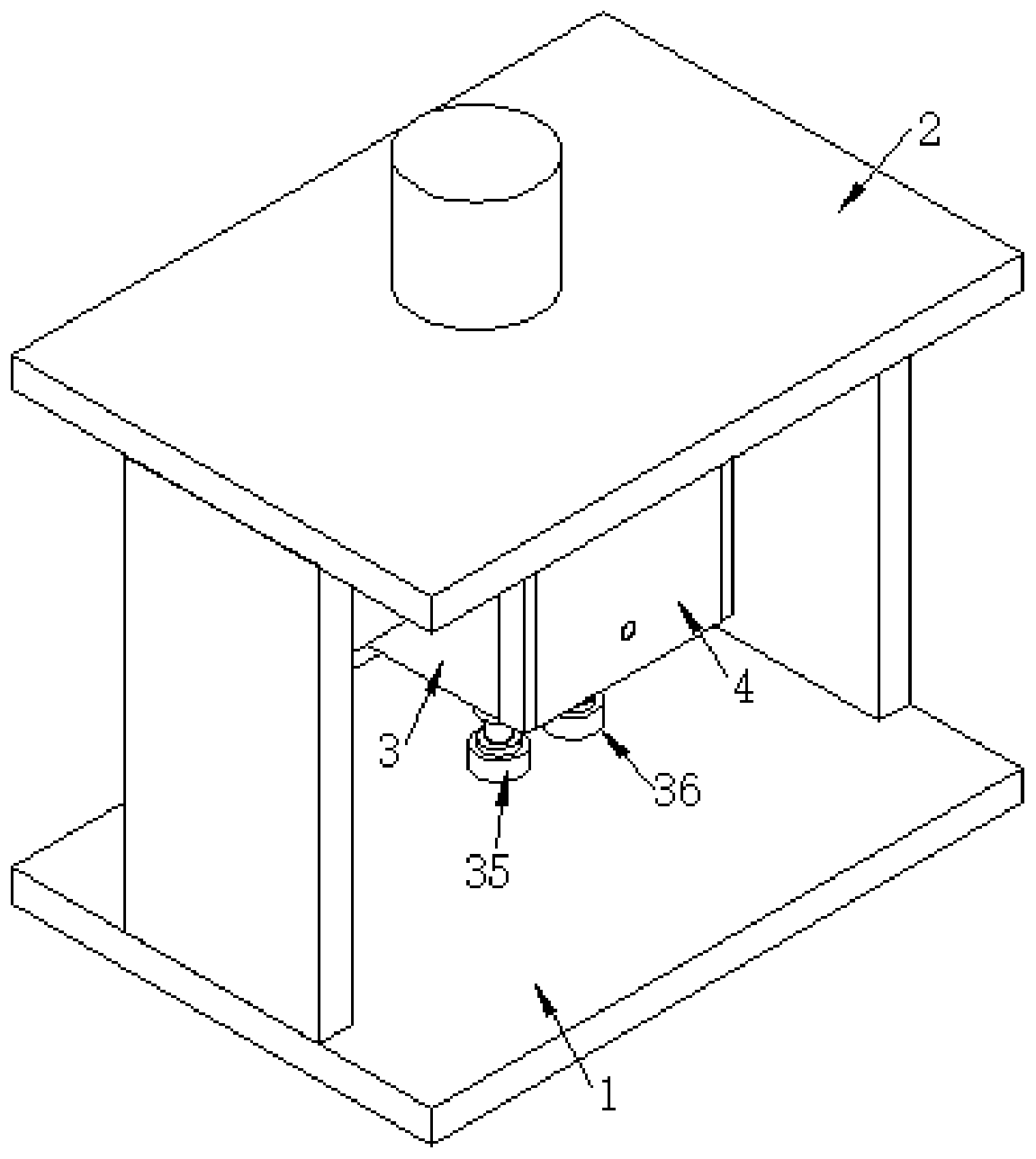

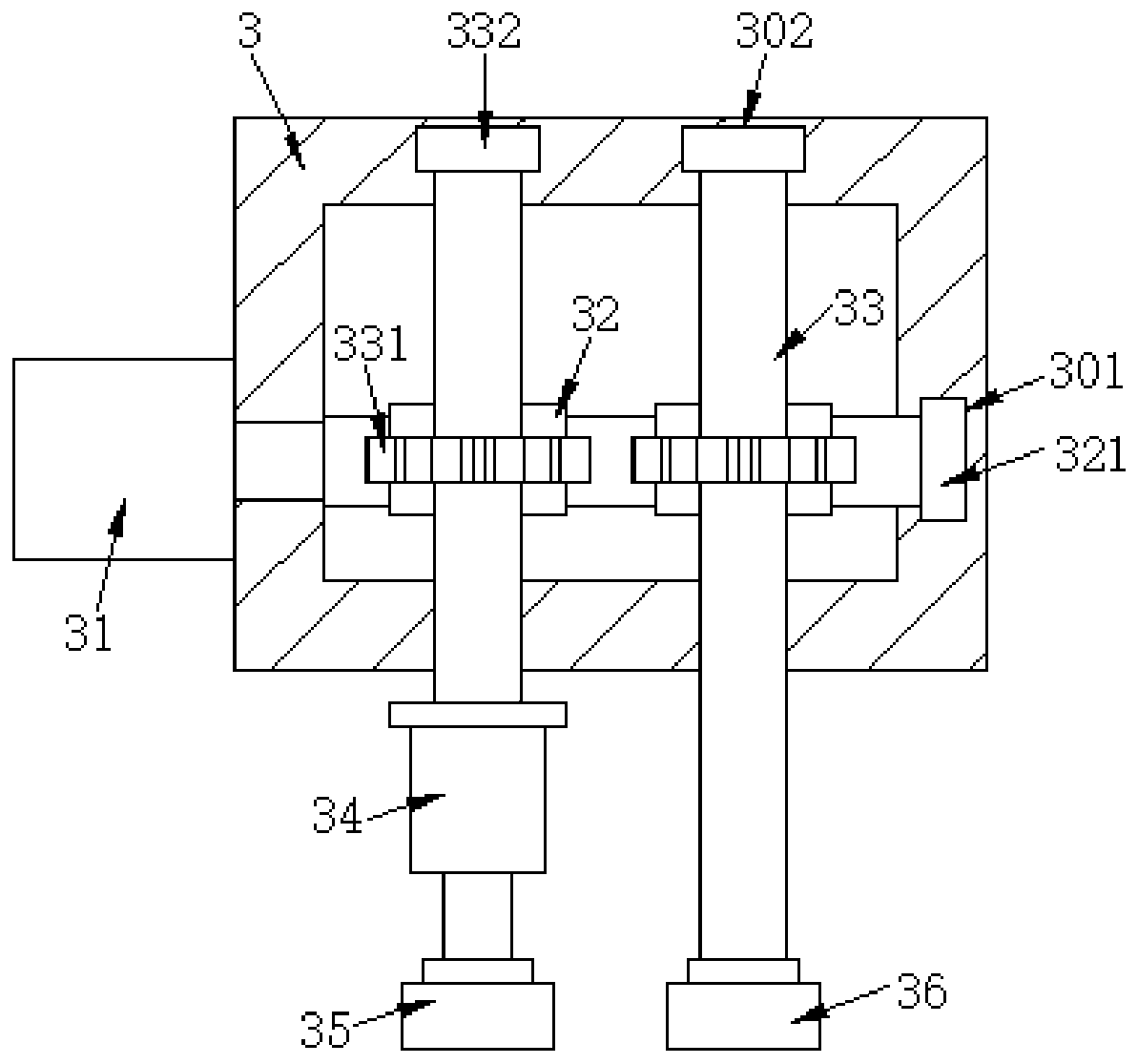

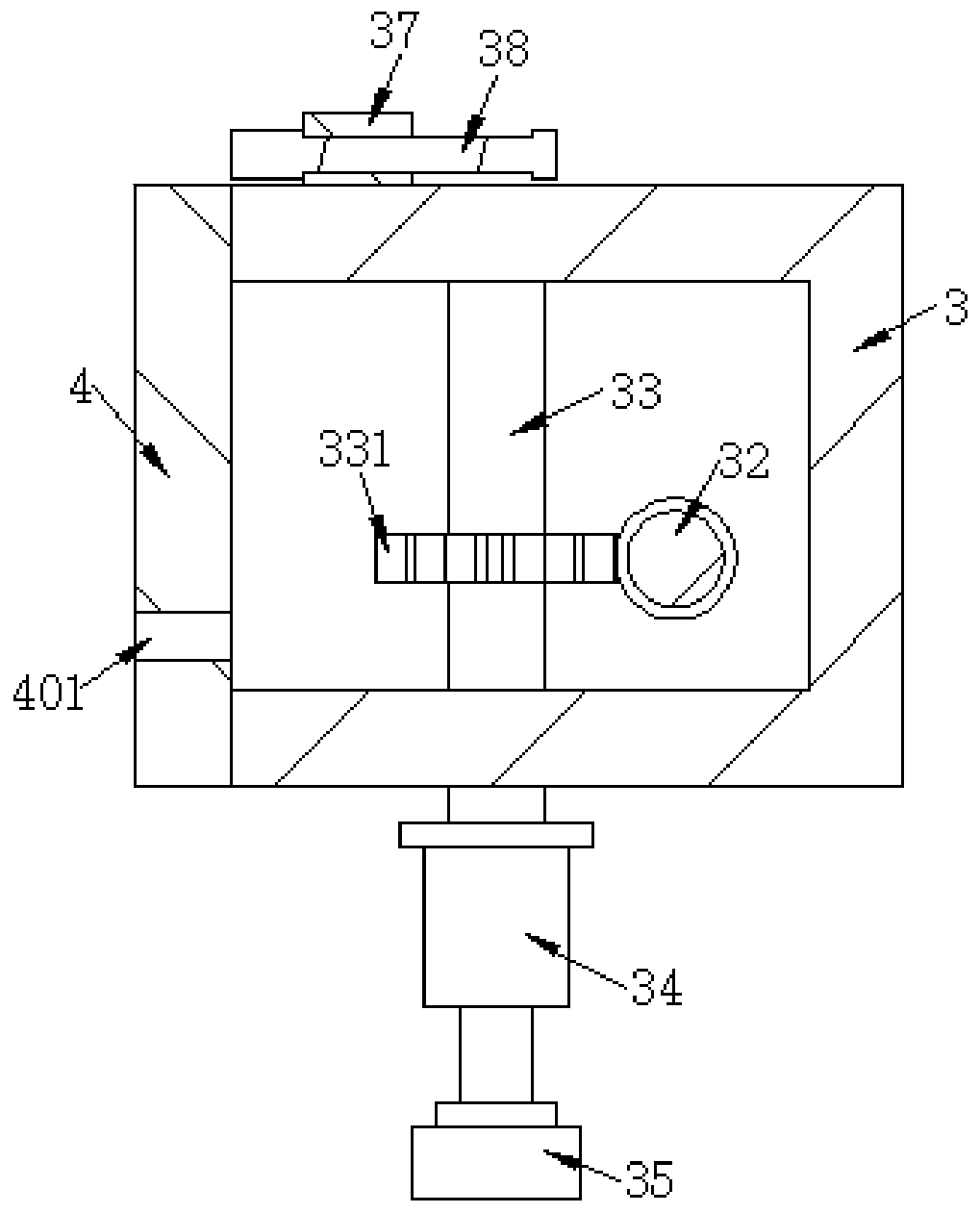

[0021] see Figure 1~5 , in the embodiment of the present invention, a kind of multistage grinder for mechanical equipment production, comprises workbench 1 and top plate 2, and the bottom of top plate 2 is provided with driving box 3, and the side wall of driving box 3 is fixedly connected with motor 31, and motor 31 is connected with external power supply Electrically connected, the output end of the motor 31 runs through the drive box 3, the output end of the motor 31 is fixedly connected with a worm 32, the inner side of the drive box 3 is connected with two rotating shafts 33, the outer walls of the two rotating shafts 33 are fixedly connected with a worm gear 331, and the two worm gears 331 are all meshed with the worm 32, the bottom ends of the two rotating shafts 33 run through the drive box 3, and the bottom ends of the two rotating shafts 33 extend to the outside of the driving box 3, and the bottom ends of one of the rotating shafts 33 are fixedly connected with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com