A kind of electroless plating comprehensive wastewater treatment method

A treatment method and technology for comprehensive wastewater treatment, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor biodegradability, large environmental pollution, and high pollutant indicators of chemical plating wastewater, Achieve stable effect, huge social and economic benefits, and reduce the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

[0020] When the present invention is implemented, it is provided by the following examples.

[0021] A kind of electroless plating comprehensive wastewater treatment method, comprises the following steps:

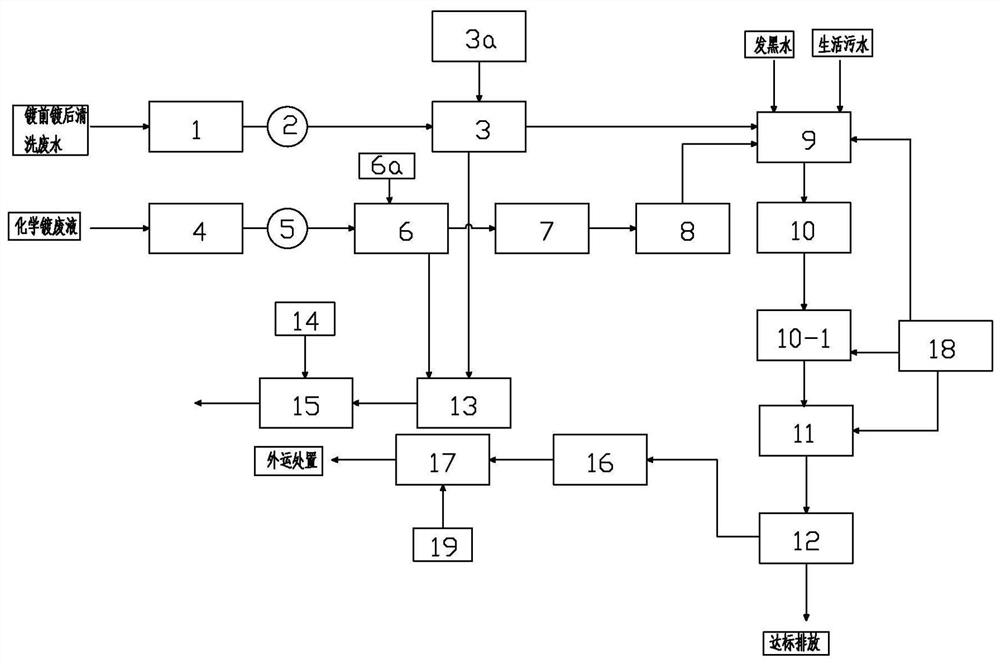

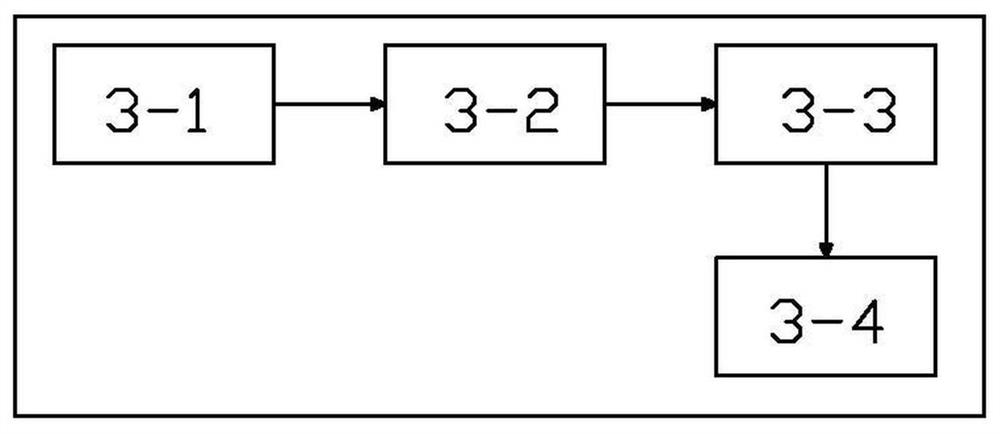

[0022] (1) Waste water removal of slick oil and suspended solids: the pre-plating and post-plating cleaning wastewater generated by the hydraulic prop during chemical plating enters the cleaning waste liquid pool 1, and is pumped into the cleaning wastewater treatment integrated machine 3 through the first sewage lifting pump 2 The cleaning wastewater treatment integrated machine 3 is an integrated structure composed of the first pH adjustment tank 3-1, the neutralization sedimentation tank 3-2, the demulsification tank 3-3 and the flocculation air flotation tank 3-4. The first pH adjustment tank 3 The outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com