Stabilizing treatment system for cellulose acetate and derivatives thereof

A cellulose acetate, stabilization treatment technology, applied in chemical/physical/physical-chemical fixed reactors, chemical industry, chemical instruments and methods, etc., can solve the problem of insufficient stability of cellulose acetate and its derivatives, Fully meet the problems of cellulose acetate and its derivatives, affecting the quality of cellulose acetate products, and achieve the effect of ensuring the effect of stabilization treatment, improving the heating uniformity and heating effect, and improving the stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

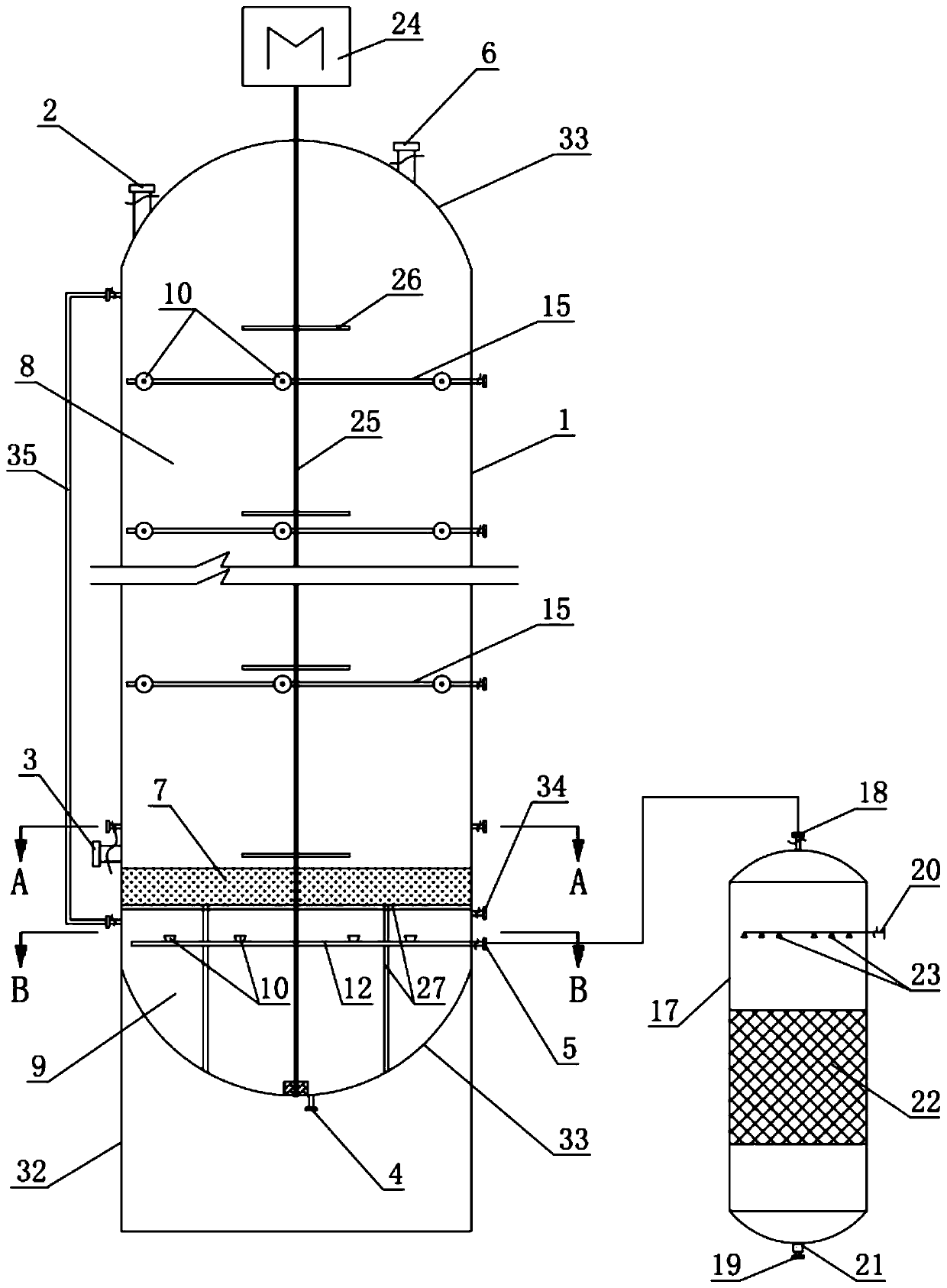

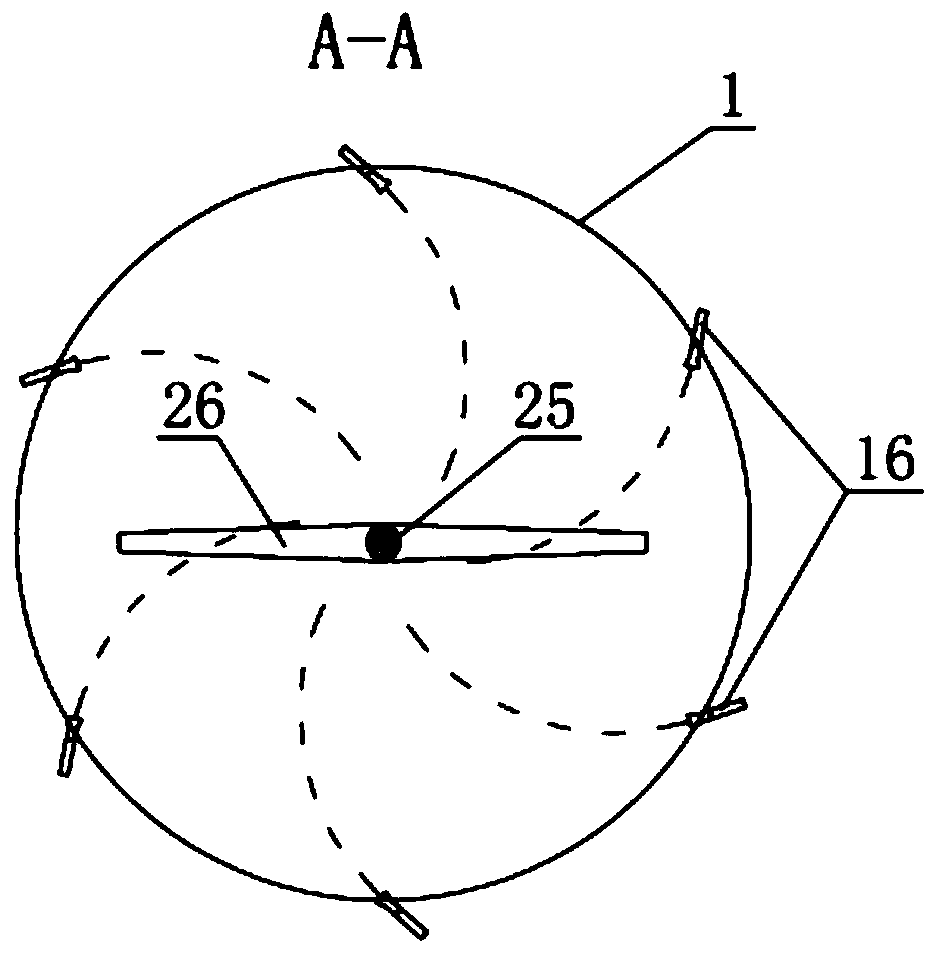

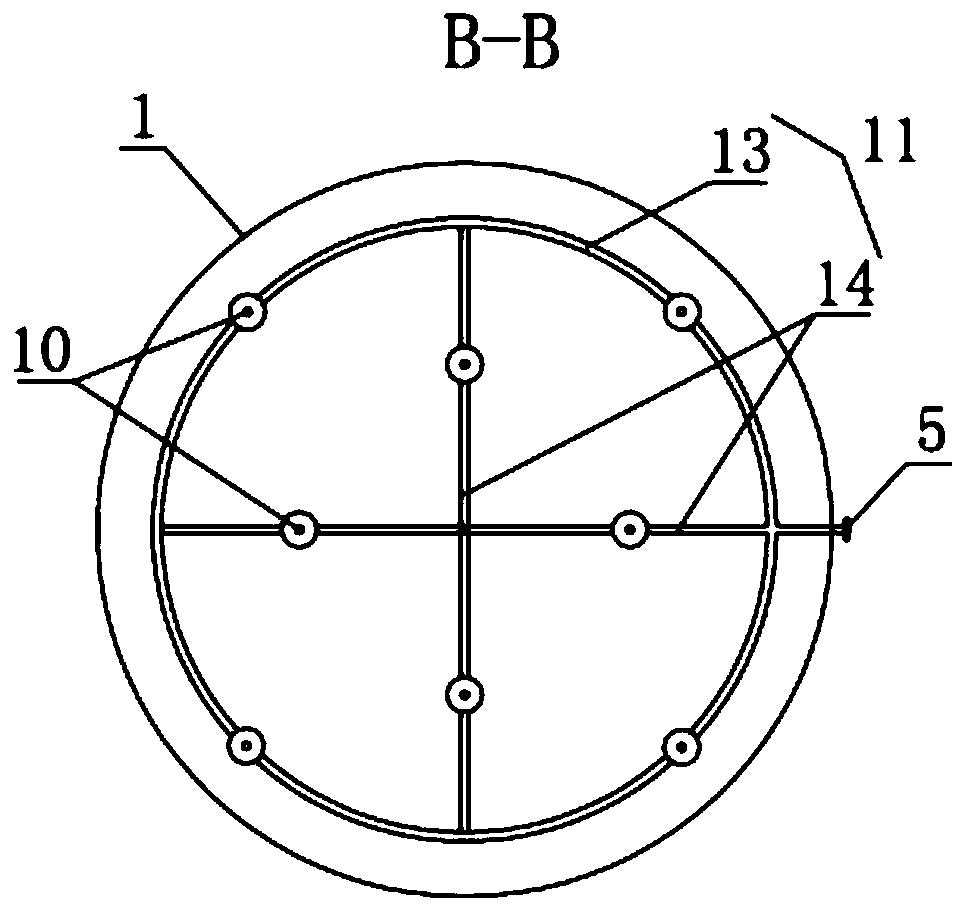

[0024] Such as Figure 1 to Figure 5 As shown in , the stabilized treatment system for cellulose acetate and its derivatives thereof according to the present invention comprises a cylinder body 1 provided with a sealing head 33 at the upper and lower ends, and the cylinder body 1 is respectively provided with a feed port 2, a discharge port Port 3, liquid discharge port 4, air inlet 5, and air outlet 6; a filter bottom net 7 is arranged at the bottom of the cylinder body 1, and the inner space of the cylinder body 1 is divided into the treatment at the top through the filter bottom net 7 Zone 8 and the liquid accumulation zone 9 below; the feed inlet 2 is arranged on the cylinder corresponding to the top of the treatment zone 8; the discharge outlet 3 is arranged on the cylinder corresponding to the bottom of the treatment zone 8 , and the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com