Humic acid-containing soil conditioner and preparation method thereof

A soil conditioner, humic acid technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of rough preparation process, single component, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

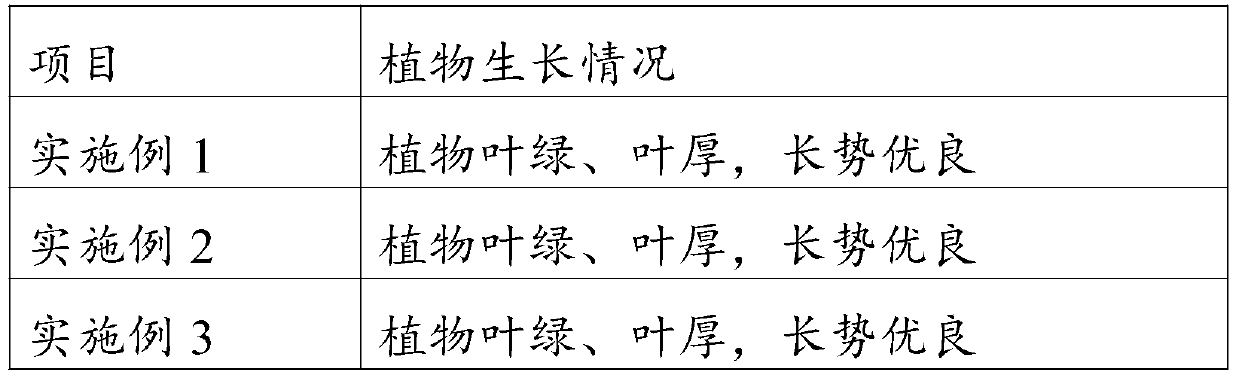

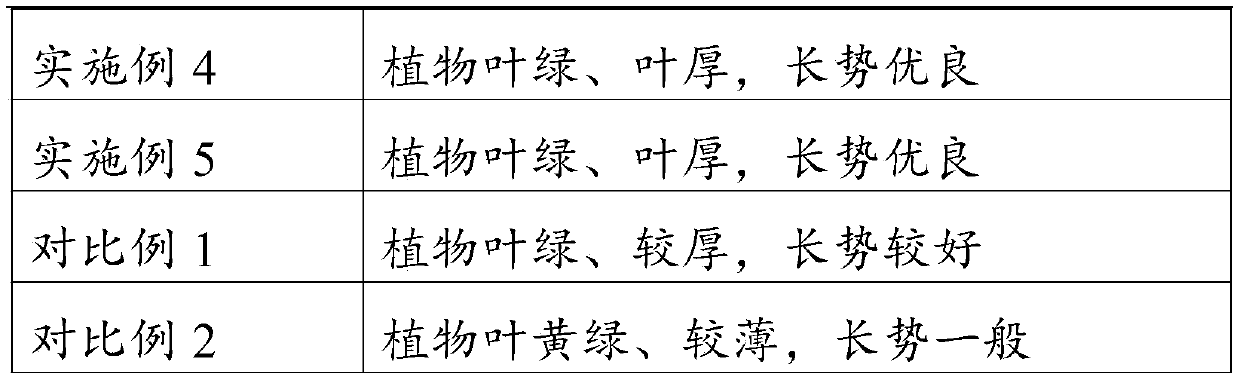

Examples

Embodiment 1

[0021] A humic acid-containing soil conditioner comprising:

[0022] In parts by weight, 30 parts of organic fertilizer, 20 parts of humic acid, 40 parts of natural peat, 30 parts of thiophanate-methyl, 2 parts of KOH solution, 20 parts of weathered coal, 20 parts of calcium oxide, 15 parts of magnesium oxide, compound bacteria 15 doses.

[0023] The preparation method of above-mentioned humic acid-containing soil conditioner, comprises the steps:

[0024] (1) Raw material pretreatment: mix and pulverize natural peat, weathered coal, calcium oxide and magnesium oxide, add KOH solution after pulverization and stir thoroughly, heat the mixture to 80°C and keep it for 30min, then cool to room temperature, and then Return to temperature at 50°C for 30 minutes.

[0025] (2) Primary fermentation: add the compound microbial agent and stir for 15 minutes, then carry out primary fermentation at 55°C and pH 8 for 3 days.

[0026] (3) Secondary fermentation: add organic fertilizer and...

Embodiment 2

[0032] A humic acid-containing soil conditioner comprising:

[0033] In parts by weight, 25 parts of organic fertilizer, 25 parts of humic acid, 35 parts of natural peat, 25 parts of thiophanate-methyl, 3 parts of KOH solution, 25 parts of weathered coal, 25 parts of calcium oxide, 15 parts of magnesium oxide, compound bacteria 15 doses.

[0034] The preparation method of above-mentioned humic acid-containing soil conditioner, comprises the steps:

[0035] (1) Raw material pretreatment: mix and pulverize natural peat, weathered coal, calcium oxide, and magnesium oxide, add KOH solution after pulverization and stir thoroughly, heat the mixture to 90°C and keep it for 30min, then cool to room temperature, and then Return to temperature at 60°C for 40 minutes.

[0036] (2) Primary fermentation: add the compound microbial agent and stir for 15 minutes, then carry out primary fermentation at 50°C and pH 9 for 2 days.

[0037] (3) Secondary fermentation: add organic fertilizer an...

Embodiment 3

[0043] A humic acid-containing soil conditioner comprising:

[0044] In parts by weight, 35 parts of organic fertilizer, 23 parts of humic acid, 45 parts of natural peat, 20 parts of thiophanate-methyl, 3 parts of KOH solution, 22 parts of weathered coal, 20 parts of calcium oxide, 20 parts of magnesium oxide, compound bacteria 20 doses.

[0045] The preparation method of above-mentioned humic acid-containing soil conditioner, comprises the steps:

[0046] (1) Raw material pretreatment: mix and pulverize natural peat, weathered coal, calcium oxide, and magnesium oxide, add KOH solution after pulverization and stir thoroughly, heat the mixture to 95°C and keep it for 35min, then cool to room temperature, and then Return to temperature at 58°C for 45 minutes.

[0047] (2) Primary fermentation: add the compound microbial agent and stir for 15 minutes, then carry out primary fermentation at 60°C and pH 7.5 for 2 days.

[0048] (3) Secondary fermentation: add organic fertilizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com