Cable clamp production technology

A cable fixture and production process technology, which is applied in the field of cable fixture production technology, can solve the problems that the cable fixture cannot be guaranteed to resist thermal shock damage, the high vacuum degree of the cavity cannot be achieved, and the gas cannot be completely eliminated, so as to avoid thermal shock. Effects of damage and internal thermal stress concentration, good resistance to thermal shock damage, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A production process of a cable clamp, comprising:

[0053] S1. Preparation of molten metal: 20 parts by mass of steel block, 80 parts of aluminum block and 5 parts of titanium block are placed in the melting furnace to smelt the molten metal. Placed in the order of the top, the melting temperature is 1600°C, and the preliminary molten metal is obtained, and the slagging agent powder is evenly sprinkled on the preliminary molten metal, and then stirred at a speed of 300r / min for 25min, and the slag removal treatment is performed after the stirring is completed to obtain the molten metal ;

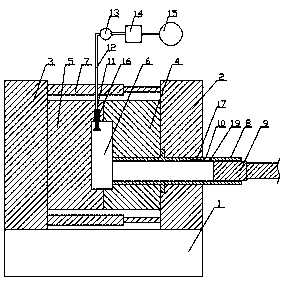

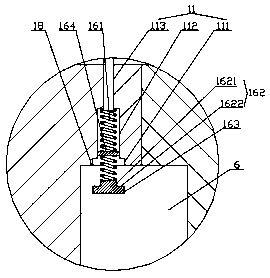

[0054] S2. Die-casting: hydraulically inject the metal prepared in step S1 into a special vacuum die-casting mold, the temperature of the die-casting mold is 350°C, the die-casting pressure is 80MPa, and the vacuum degree in the vacuum die-casting mold is 50KPa, to obtain a fixture casting;

[0055] S3. Remove the riser: take out the fixture casting, clean and remove the riser and b...

Embodiment 2

[0058] A production process of a cable clamp, comprising:

[0059] S1. Preparation of molten metal: 25 parts by mass of steel block, 85 parts of aluminum block and 8 parts of titanium block are placed in the smelting furnace to smelt the molten metal. Placed in the order of the top, the smelting temperature is 1650°C, and the preliminary molten metal is obtained, and the slagging agent powder is evenly sprinkled on the preliminary molten metal, and then stirred at a rotation speed of 350r / min for 28min, and the slag removal treatment is performed after the stirring is completed, to obtain the molten metal ;

[0060] S2. Die-casting: hydraulically inject the metal prepared in step S1 into a special vacuum die-casting mold, the temperature of the die-casting mold is 380°C, the die-casting pressure is 85MPa, and the vacuum degree in the vacuum die-casting mold is 55KPa, to obtain a fixture casting;

[0061] S3. Remove the riser: take out the fixture casting, clean and remove the...

Embodiment 3

[0064] A production process of a cable clamp, comprising:

[0065] S1. Preparation of molten metal: 30 parts by mass of steel block, 90 parts of aluminum block and 10 parts of titanium block are placed in the melting furnace to smelt the molten metal. Place in the order of the top, the melting temperature is 1700°C, to obtain the preliminary molten metal, evenly sprinkle the slagging agent powder on the preliminary molten metal, and then stir for 30min at a speed of 400r / min, after the stirring is completed, perform slag removal treatment to obtain molten metal ;

[0066] S2. Die-casting: hydraulically inject the metal prepared in step S1 into a special vacuum die-casting mold, the temperature of the die-casting mold is 400°C, the die-casting pressure is 90MPa, the vacuum degree in the vacuum die-casting mold is 60KPa, and the fixture casting is obtained;

[0067] S3. Remove the riser: take out the fixture casting, clean and remove the riser and burrs;

[0068] S4. Shot blas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com