Steam drying equipment for preparing soluble humic acid

A drying equipment, humic acid technology, applied in drying, dryer, lighting and heating equipment and other directions, to achieve the effect of improving maintenance efficiency, avoiding replacement, and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

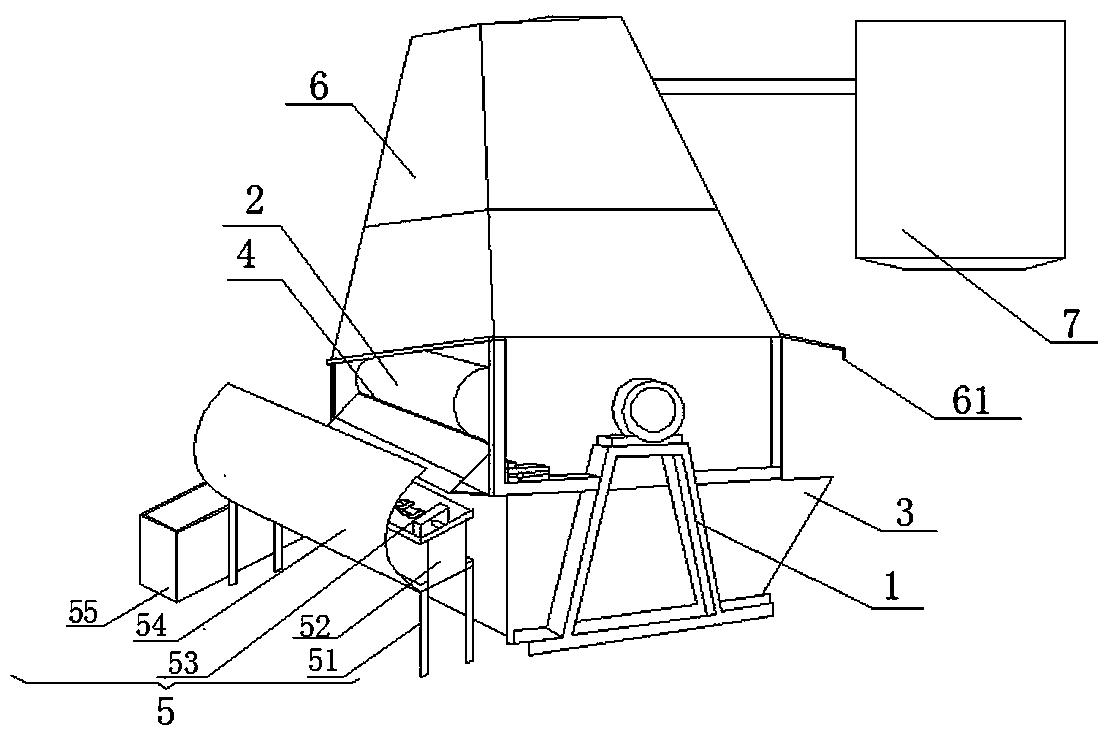

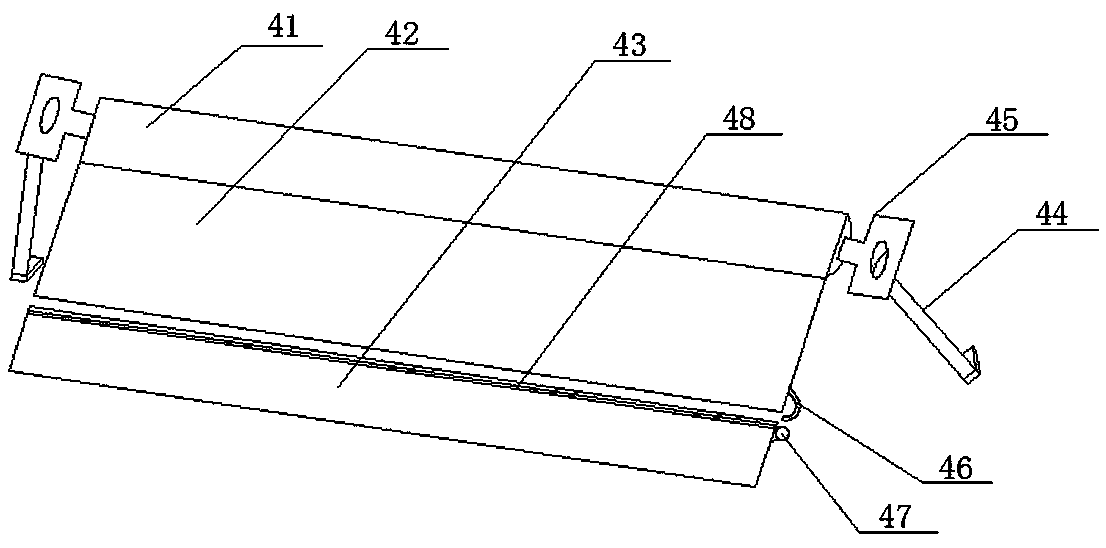

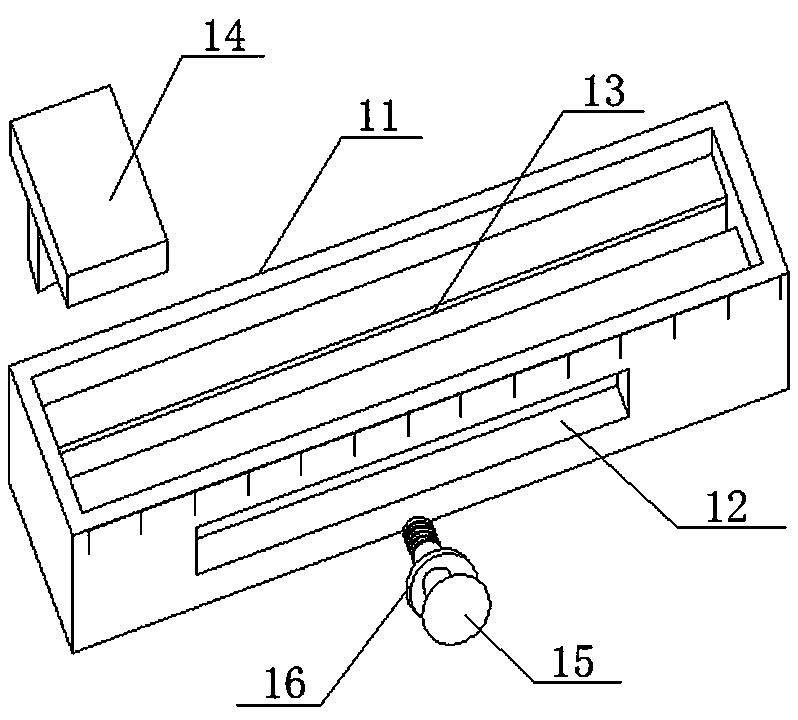

[0024] Example: such as figure 1 and figure 2 The shown steam drying equipment for preparing soluble humic acid includes: a fixed frame 1, a steam drum 2, a liquid material trough 3 and a scraping device 4, and the steam drum 2 is arranged on the fixed frame 1 and located on the liquid material Above the groove 3, the scraping device 4 includes a scraper 41, a feeding plate 42, an extension plate 43 and a connecting piece 44. Ear piece 45, the bottom end is fixedly connected with the feeding plate 42, and the convex arc surface at the top is tangent to the steam drum 2; the feeding plate 42 is rotatably connected with the extension plate 43, and the extension plate 43 is fixedly connected with the fixed frame 1; One end of piece 44 is fixedly connected with lug piece 45, and the other end is connected with fixed frame 1 and can adjust position; Adjust the position of two connectors on fixed frame, change the tangential position of scraper knife and steam drum.

[0025] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com