Coil pipe type heat absorber with internal thread pipe

A technology of internally threaded pipes and heat absorbers, which can be used in heat exchanger shells, solar collectors, tubular elements, etc., and can solve the problems of high cost and complicated control of thermocouples and cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

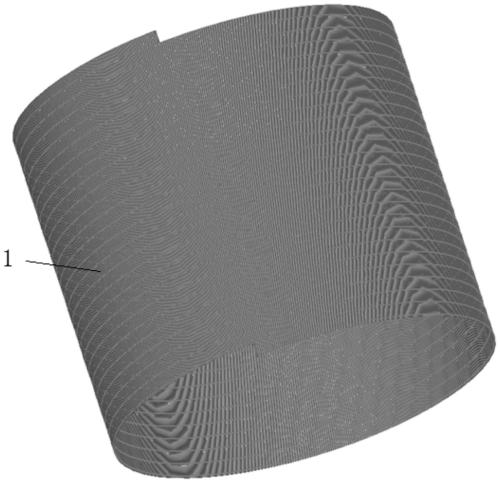

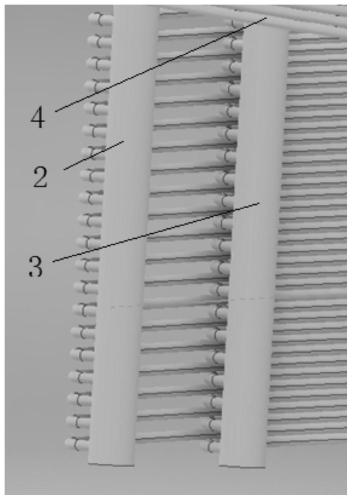

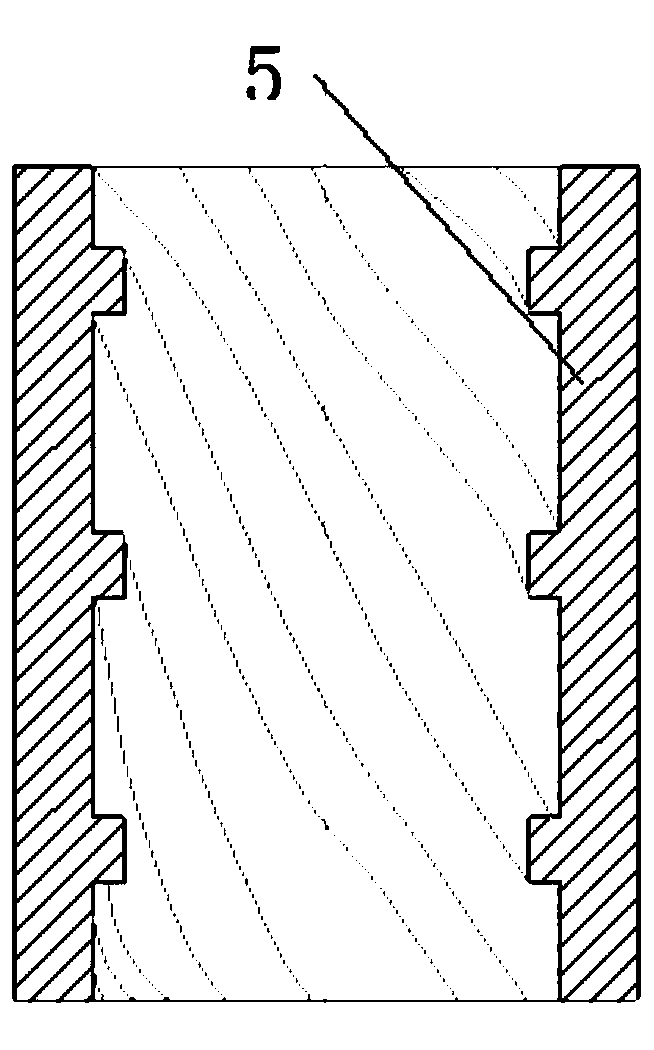

[0017] combined with Figure 1-3 Description of the implementation mode: a coil type heat absorber with internal threaded pipe,

specific Embodiment approach 1

[0018] Specific embodiment one: it includes a heat absorber coil tube panel 1, an inlet header 2 and an outlet header 3, and the heat absorber coil tube panel 1 is a plurality of spiral heat-absorbing tubes 5 coiled and arranged, The side inlet end of the heat absorber coil tube panel 1 is connected to the inlet header 2 , and the side outlet end of the heat absorber coil tube panel 1 is connected to the outlet header 3 .

[0019] Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 2

[0020] Embodiment 2: The heat absorber coil tube panel 1 is provided with 2 or 4 spiral coil heat absorber circuits.

[0021] Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com