Method for analyzing and determining content of hexafluoroacetone

A technology of hexafluoroacetone and its determination method, which is applied in the field of chemical analysis, can solve the problems of being unsuitable for large-scale production and expensive instruments, and achieve the effects of low test price, reliable results and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

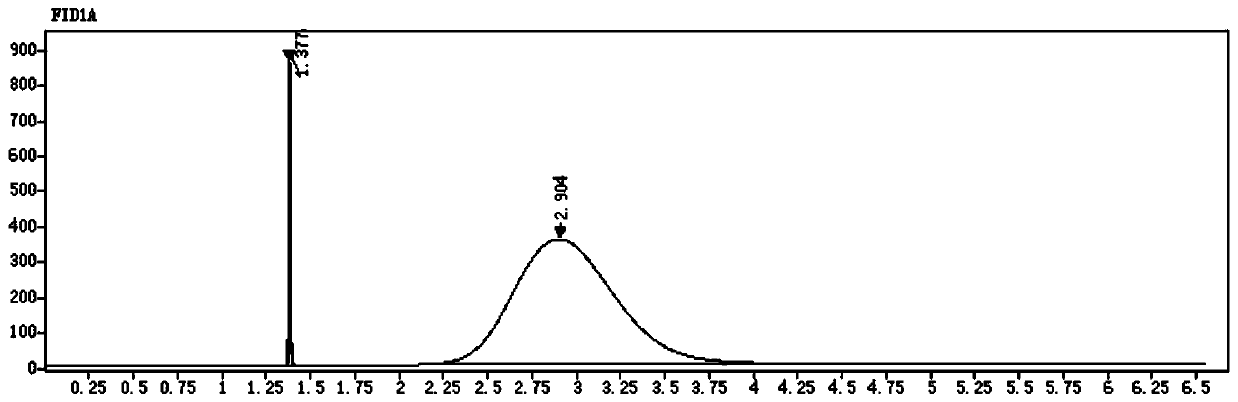

Image

Examples

Embodiment 1

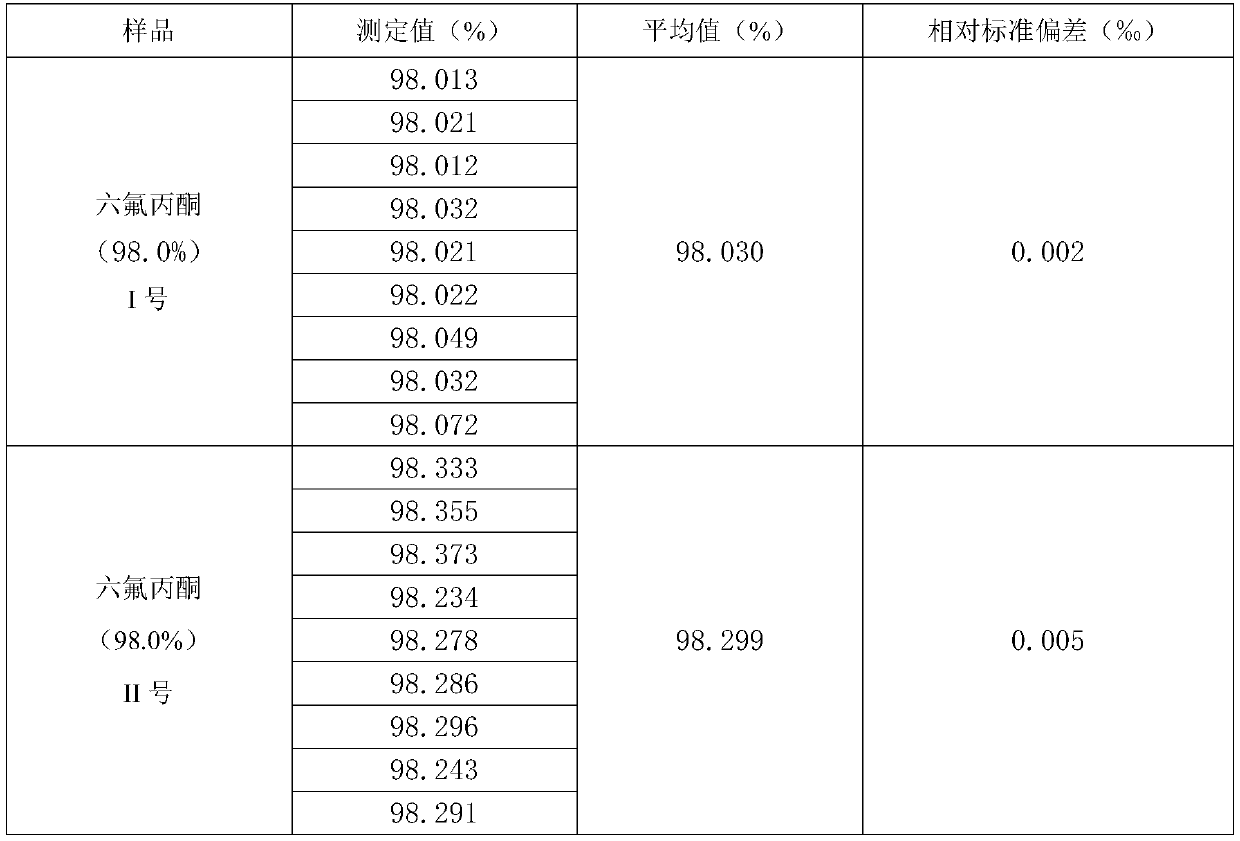

[0021] The method of the present invention is used to determine the content of hexafluoroacetone in two samples: wherein, "No. 1" is hexafluoroacetone with a purity greater than 98.0% produced by Shandong Huaxia Shenzhou New Material Co., Ltd. "No. II" is hexafluoroacetone produced by Shandong Dongyue Future Hydrogen Energy Materials Co., Ltd.

[0022] 1.1 Instrument

[0023] Agilent 7890B chromatograph produced in the United States.

[0024] 1.2 Chromatographic conditions

[0025] Detector: hydrogen flame detector;

[0026] Chromatographic column: HP-INNOwax; column length: 0.32mm*0.25μm*30m, liquid film thickness is 0.25um;

[0027] Column temperature: program temperature rise, the initial temperature is 80°C, keep for 1-2min, then increase by 20°C per minute, after rising to 180°C, keep for 5min.

[0028] Injection port temperature: 100°C;

[0029] Detector temperature: 300°C;

[0030] Carrier gas: high-purity nitrogen;

[0031] Carrier gas flow rate: 1.2mL / min;

[...

Embodiment 2

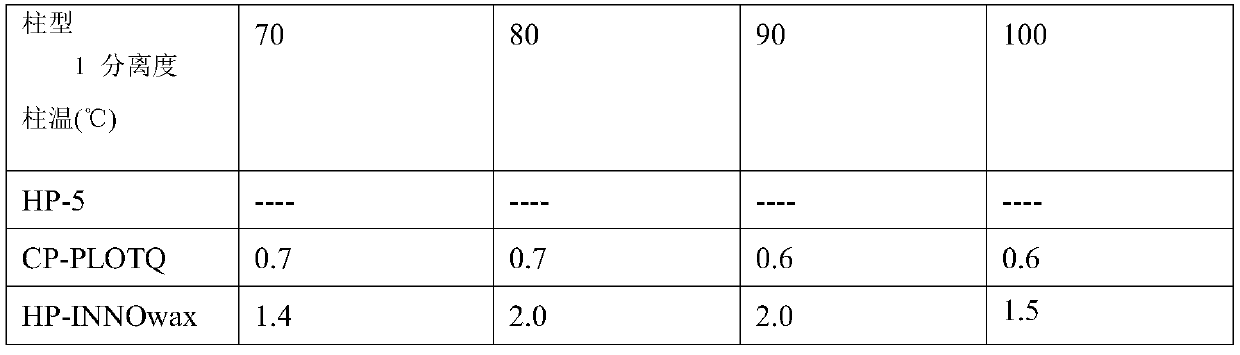

[0046] Embodiment 2: the selection experiment of chromatographic conditions

[0047] The HP-5, CP-PLOTQ, and HP-INNOwax aging capillary columns with a liquid film thickness of 0.25um were installed on the Agilent 7890B chromatograph, and the separation test was carried out at different column temperatures. See Table 2. The HP-5, CP-PLOTQ, and HP-INNOwax are chromatographic column types.

[0048] Table 2 The resolution of the chromatographic column with a liquid film thickness of 0.25um at different temperatures

[0049]

[0050] Note: The resolution can indicate the separation of each component in the chromatographic column. When the resolution is greater than 1.5, the adjacent two chromatographic peaks can be completely separated. If the resolution is good, the measurement results can have sufficient parallelism and accuracy.

[0051] "----" means that the peak cannot be separated.

[0052] In summary, it can be seen that the HP-INNOwax with a liquid film of 0.25um is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com