Method for testing surface pollution pressure resistance of insulator coated with anti-pollution flashover coating

A technology of anti-pollution flashover coating and testing method, which is applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve the problems of prolonging the test progress, low pollution efficiency, and a certain amount of time for drying, so as to extend the test cycle , the effect of uniform pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

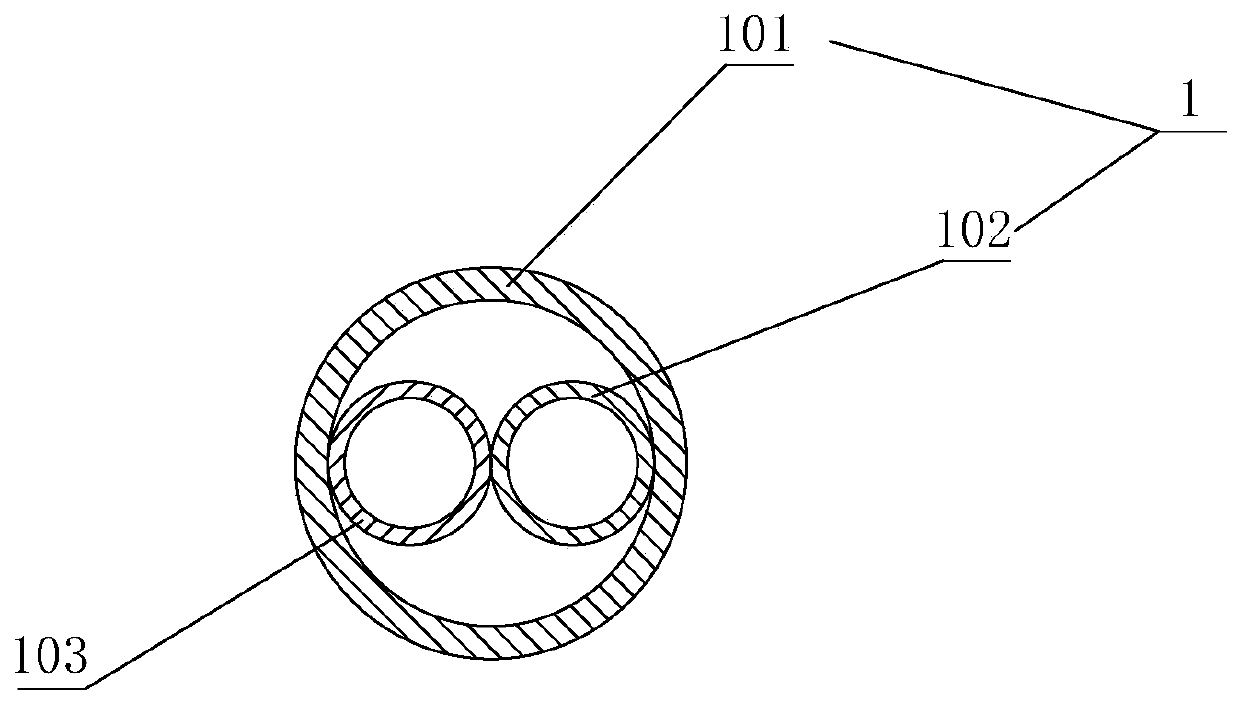

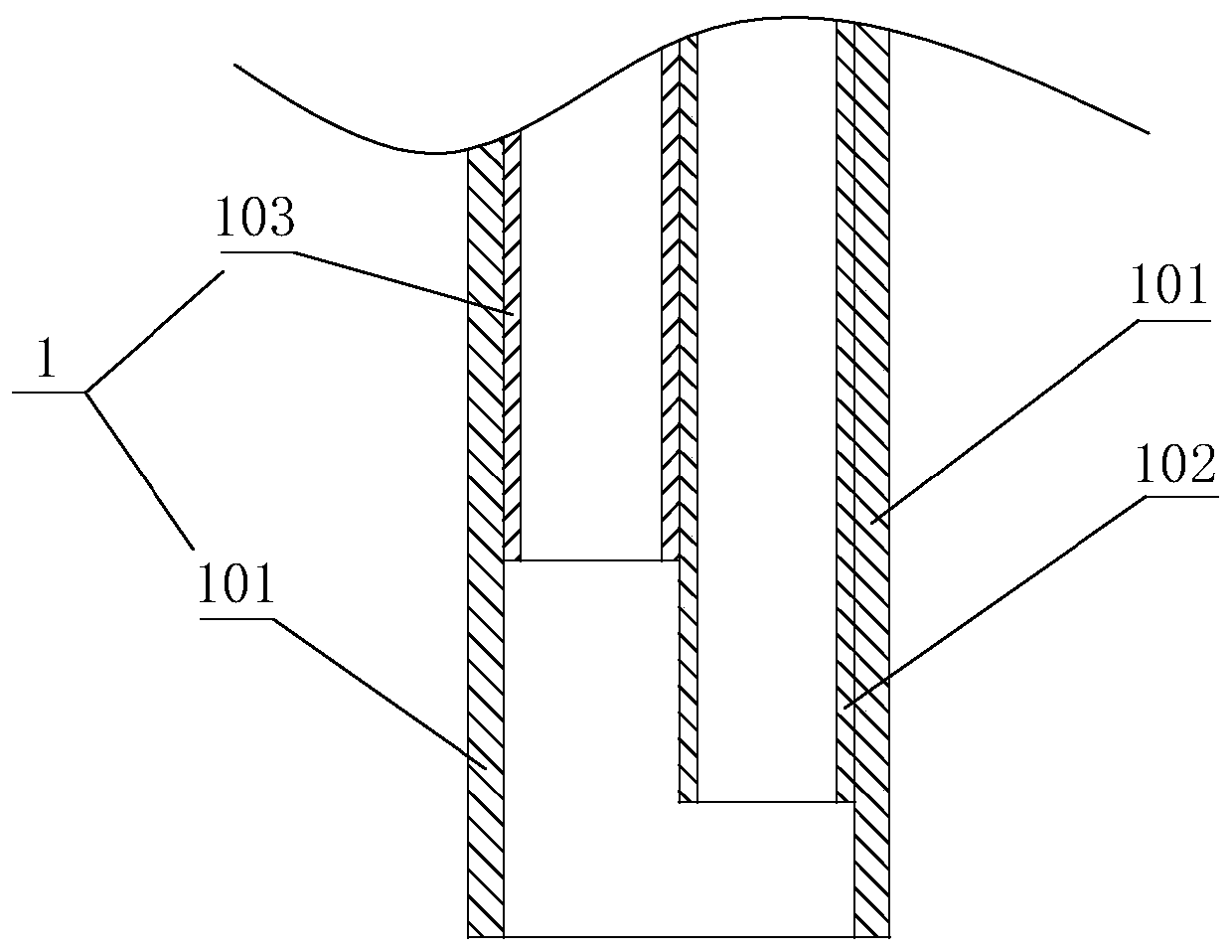

[0087] A method for testing the surface pollution withstand voltage performance of insulators coated with anti-pollution flashover coatings, using U160B type insulators, and the surface area of the insulators is 1572cm 2 , including the following steps in order:

[0088] 1) Dirt preparation: Mix diatomaceous earth, silicon dioxide with a particle size of 2 μm to 20 μm, sodium chloride, and demineralized water with a conductivity lower than 0.05 S / m to prepare the dirty liquid;

[0089] Among them, the mass of diatomite is 50g, the mass of silicon dioxide with a particle size of 2 μm to 20 μm is 5 g, the mass of sodium chloride is 11 g, and the mass of demineralized water with an electrical conductivity lower than 0.05 S / m is 250 g;

[0090] Then place the prepared dirty liquid in a drying oven to dry for 48 hours, and form solid powdery dirty after being fully dried;

[0091] In step 1), the salt density SDD is 0.1mg / cm 2 , gray density NSDD is 0.5mg / cm 2 ;

[0092] 2) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com