High-flatness soft package lithium ion battery and preparation method thereof

A lithium-ion battery and flatness technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of reducing production costs, poor battery flatness, bending and wrinkles, etc. Improved flatness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

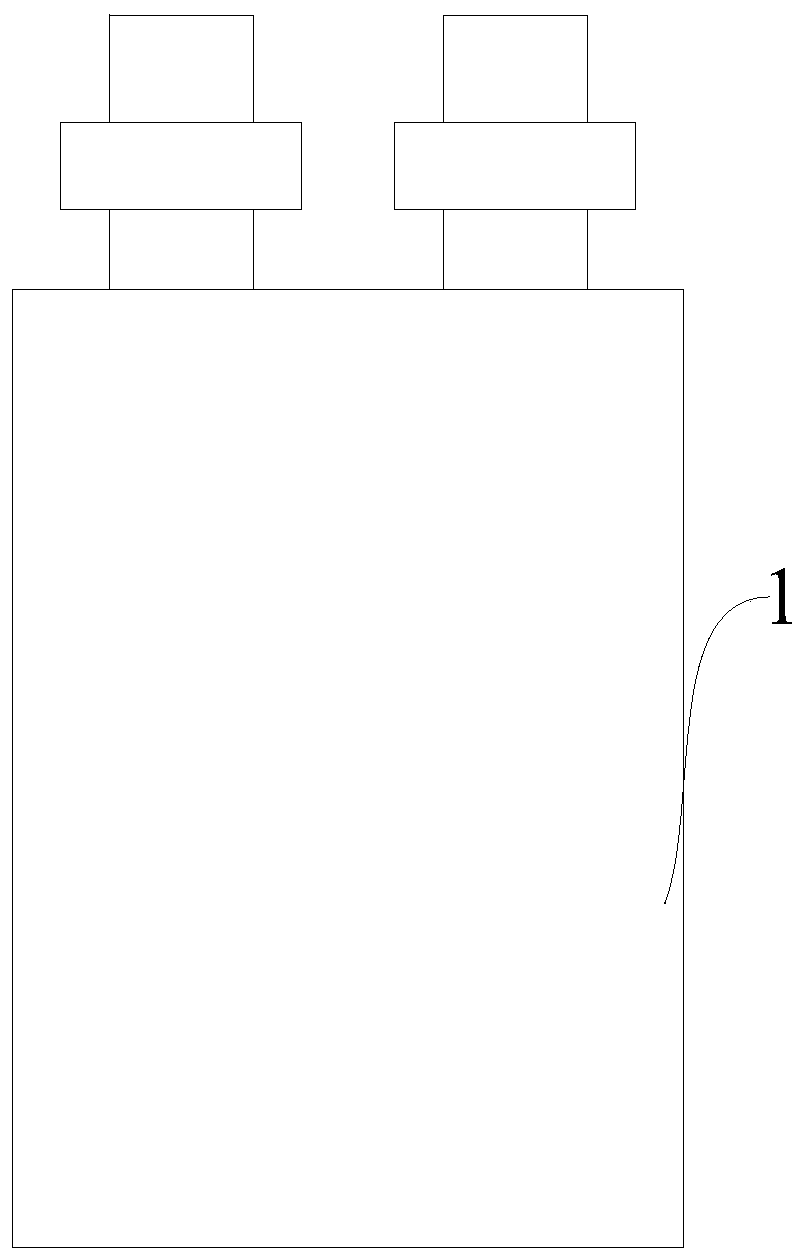

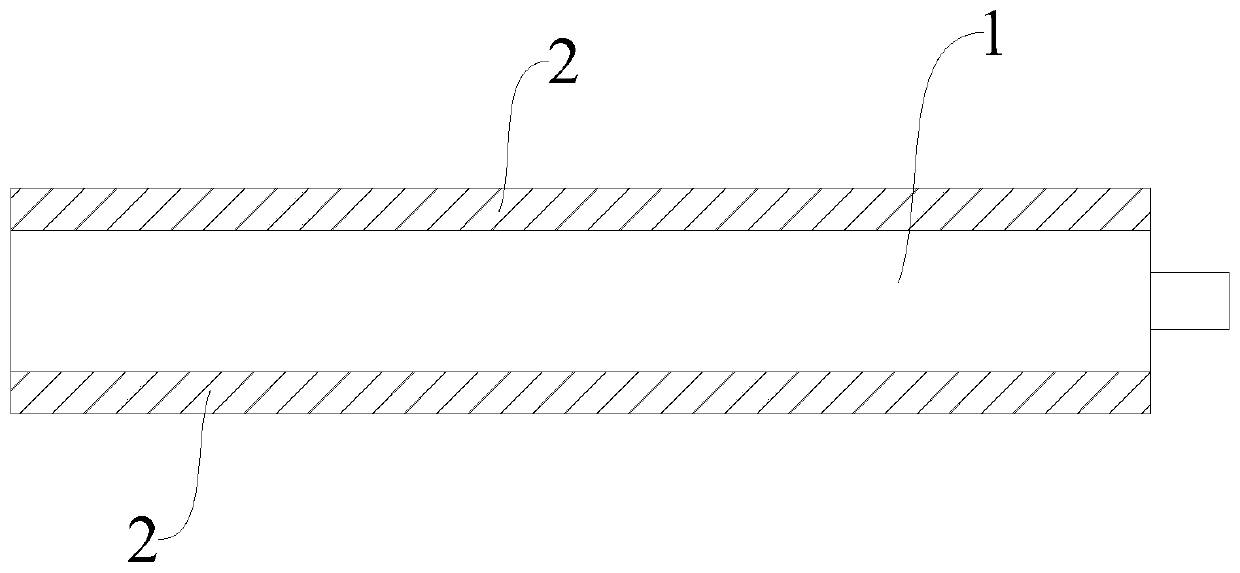

[0028] A kind of high flatness soft package lithium ion battery, such as Figure 1-3 As shown, a bare cell 1 is included, and a separator 2 is firmly pasted on the upper surface and the lower surface of the bare cell 1 respectively, and placed in an aluminum-plastic film.

[0029] Wherein, firmly sticking means that the upper surface and the lower surface of the bare cell 1 are combined with the separator 2 without gaps, for example, adhesive tape can be used.

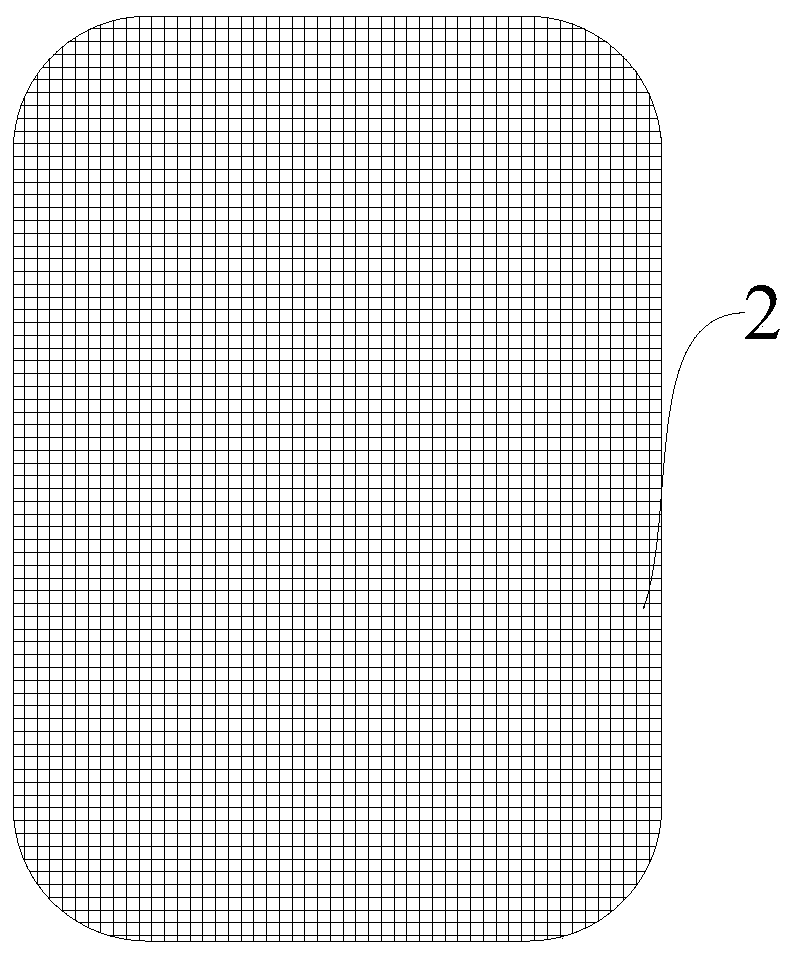

[0030] The separator 2 has uniformly distributed mesh gaps, and the surroundings of the separator 2 are chamfered.

[0031] The length of the separator 2 is 1.5 mm shorter than the length of the bare cell 1 , and the width of the separator 2 is 1.5 mm smaller than the width of the bare cell 1 .

[0032] The thickness of the partition 2 is 0.6 mm, and the radius of the chamfer around the partition 2 is 1.8 mm.

[0033] The separator 2 is made of plastic material ABS, which has certain strength, chemical stability and ...

Embodiment 2

[0035] The preparation method of the high-flatness soft-pack lithium-ion battery of the above-mentioned embodiment 1 comprises the following steps:

[0036] S1. Laminate the positive electrode sheet, separator, and negative electrode sheet in a zigzag shape and weld the tabs to obtain the bare cell 1;

[0037] S2. A separator 2 is firmly attached to the upper surface and the lower surface of the bare cell 1 described in S1;

[0038] S3. Place the bare cell with the separator 2 pasted in S2 in the aluminum-plastic film, seal the top and side, inject liquid, form, and separate the volume to obtain the high-flatness soft-pack lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com