In-situ synthesis method of CsxWO3-SiO2 composite aerogel

A composite airgel and composite gel technology, which is applied in the field of in-situ synthesis of CsxWO3-SiO2 composite airgel, can solve problems such as the uniformity of composite airgel and affect performance, achieve good infrared absorption capacity, improve Pore volume, excellent heat absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

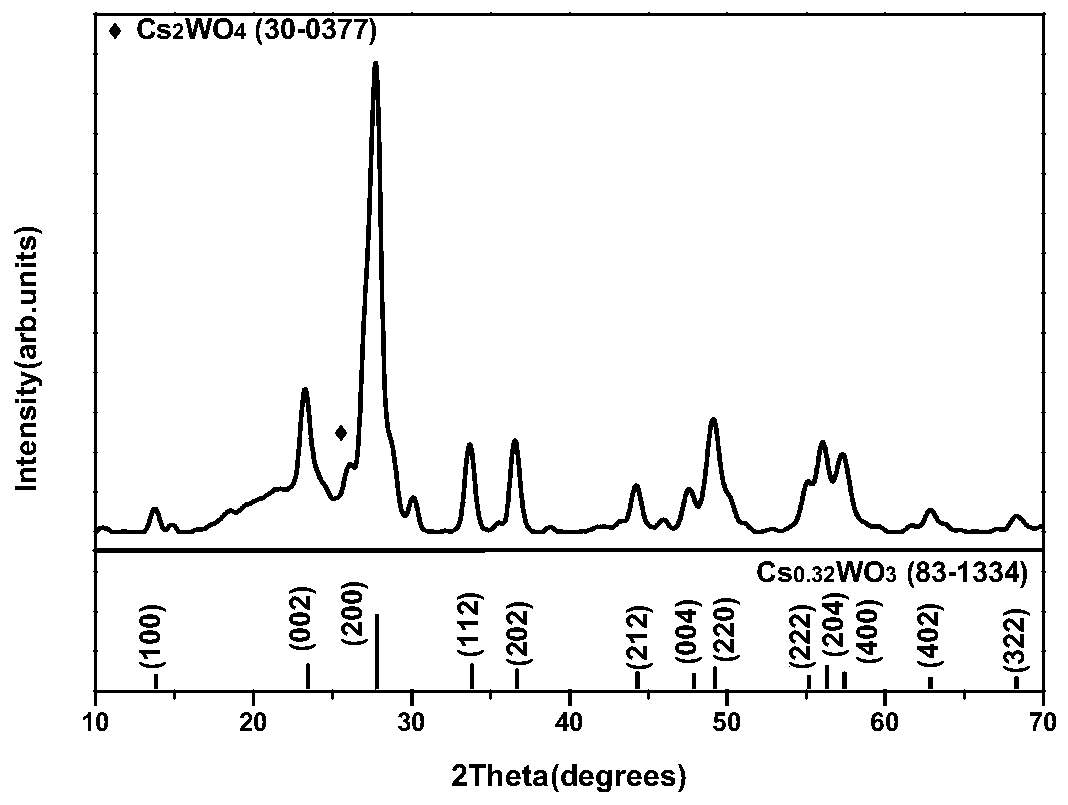

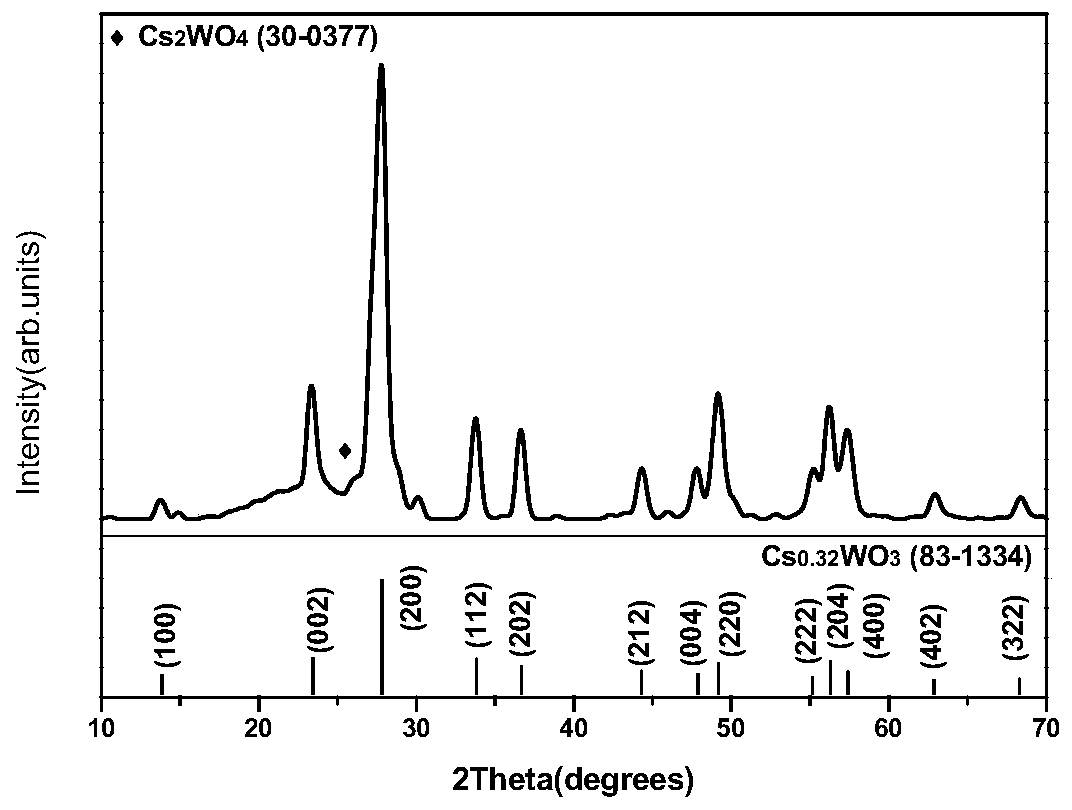

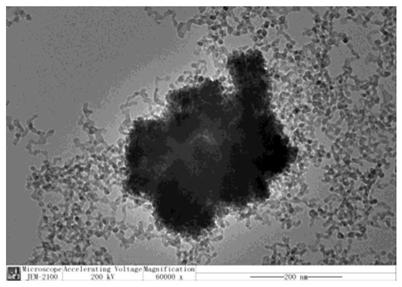

Image

Examples

preparation example Construction

[0038] a Cs x WO 3 -SiO 2 The in-situ synthesis method of composite airgel, said method comprises the following process steps:

[0039] ①Preparation of SiO by sol-gel method 2 -Cs 2 O-WO 3 Composite gel;

[0040] Using water glass and sodium tungstate as raw materials, a certain concentration of H can be obtained through styrene cation exchange resin respectively. 2 SiO 3 and H 2 WO 4 solution; measure a certain amount of H 2 SiO 3 and H 2 WO 4 solution, mix it, add an appropriate amount of cesium salt and a certain amount of organic acid, stir and mix evenly, then heat and age in a water bath at 20-90°C until gelling, and obtain SiO 2 -Cs 2 O-WO 3 Composite gel. Among them, the H 2 SiO 3 The concentration of the solution is 0.15~4.5M, preferably 0.45~2.5M; H 2 WO 4 The concentration of the solution is 0.1-4.0M, preferably 0.2-2.5M; the heating and aging temperature in a water bath is 20-90°C, preferably 30-80°C; the cesium salt can be cesium chloride, cesi...

Embodiment 1

[0053] Embodiment 1 prepares the Cs of Si / W (molar ratio)=5:1 x WO 3 -SiO 2 Composite airgel:

[0054] ① SiO 2 -Cs 2 O-WO 3 Preparation of composite gel;

[0055] Measure 9mL of industrial water glass, mix it evenly with 36mL of deionized water, and use strong acidic styrene cation exchange resin for ion exchange to obtain H 2 SiO 3 solution; weigh 1.55g Na 2 WO 4 2H 2 O, added to 9.4mL deionized water, after dissolving evenly, carry out ion exchange with strongly acidic styrene cation exchange resin to obtain H 2 WO 4 solution; measure 20 mL of H 2 SiO 3 solution, under stirring conditions, sequentially add 9.36mL of H 2 WO 4 solution, 0.846g of Cs 2 SO 4 and 5.51g of citric acid, stirred for 2 hours, and mixed thoroughly to obtain a mixed sol, and then aged the mixed sol in a water bath at 65°C until it gelled, and obtained SiO 2 -Cs 2 O-WO 3 Composite gel.

[0056] ② Preparation of Cs x WO 3 -SiO 2 Composite gel;

[0057] Measure 70mL deionized wate...

Embodiment 2

[0061] Embodiment 2 prepares the Cs of Si / W (molar ratio)=7:1 x WO 3 -SiO 2 Airgel composite particles;

[0062] ① SiO 2 -Cs 2 O-WO 3 Preparation of composite gel;

[0063] Measure 9mL of industrial water glass, mix it evenly with 36mL of deionized water, and perform ion exchange with strongly acidic styrene cation exchange resin to obtain H 2 SiO 3 solution; weigh 1.20gNa 2 WO 4 2H 2 O, added to 7.3mL deionized water, dissolved evenly, ion-exchanged with strong acidic styrene cation exchange resin to obtain H 2 WO 4 solution; measure 20mLH 2 SiO 3 Solution, under stirring condition, add 6.69mLH 2 WO 4 Solution, 0.545gCs 2 CO 3 and 3.671g of tartaric acid, stirred for 2 hours to make it fully mixed, aged in a water bath at 65°C until it gelled, and obtained SiO 2 -Cs 2 O-WO 3 Composite gel.

[0064] ② Preparation of Cs x WO 3 -SiO 2 gel,

[0065] Measure 70ml deionized water, add 4.50g tartaric acid and 0.273g Cs under stirring condition 2 CO 3 , aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com