Winding device of textile equipment

A technology of winding device and textile equipment, which is applied in the direction of textiles and papermaking, winding strips, transportation and packaging, etc. It can solve the problems of textile pulling and other problems, and achieve the effects of avoiding pulling damage, convenient use, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

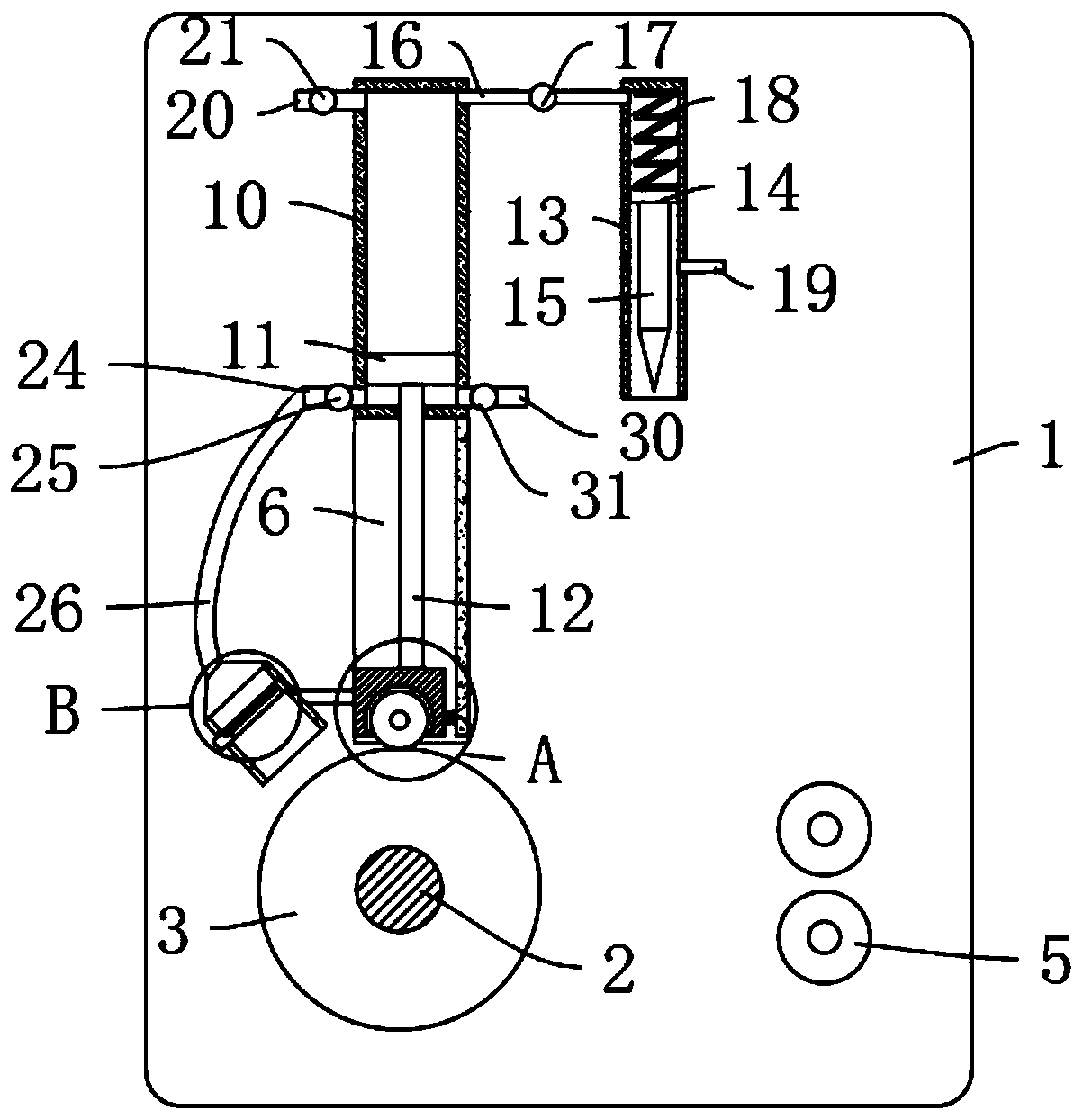

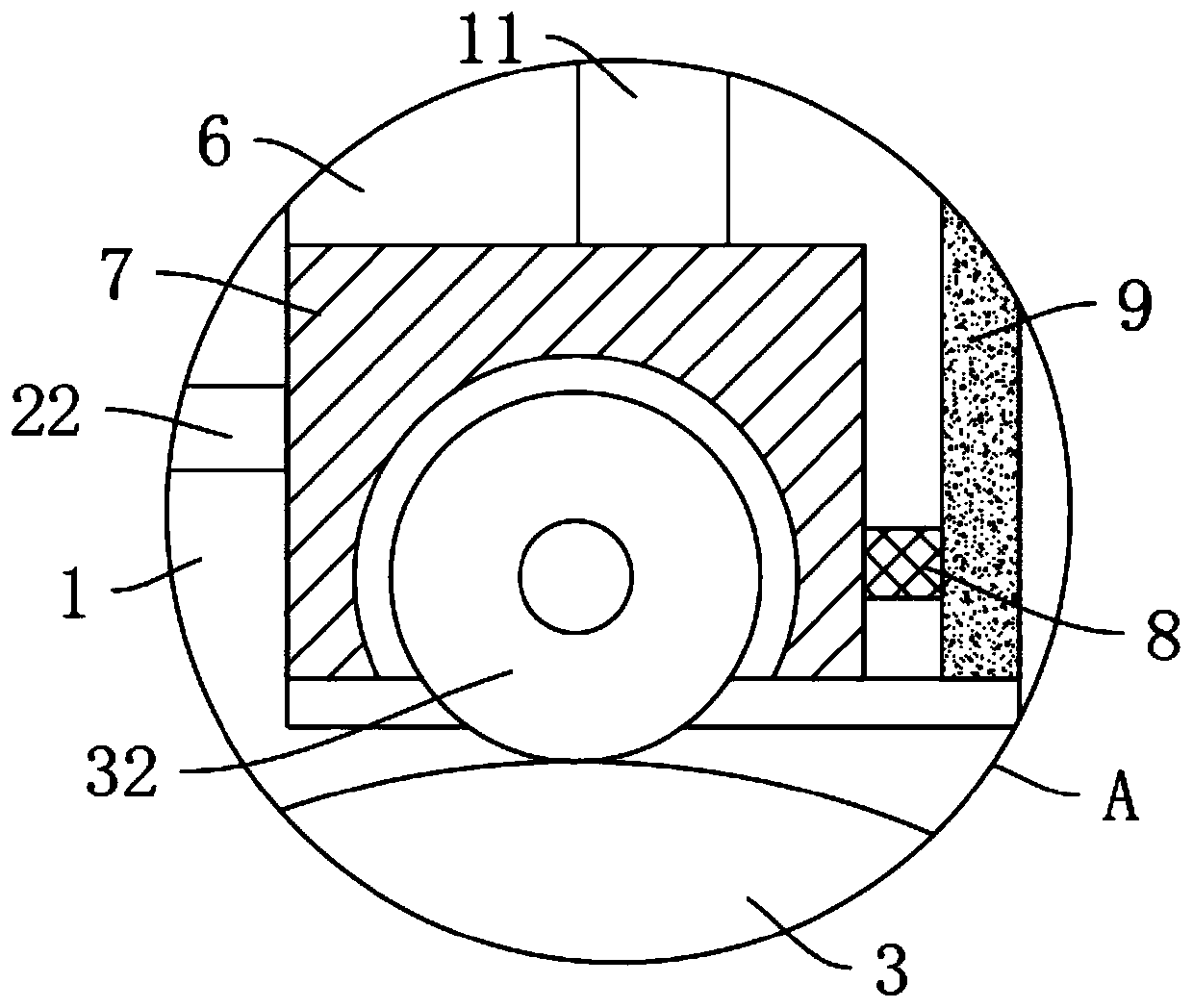

[0028] refer to figure 1 , figure 2 , Figure 4 , a winding device for textile equipment, comprising two symmetrically arranged support vertical boards 1, a rotating shaft 2 is rotatably connected between the two supporting vertical boards 1, and a reel 3 is fixedly connected to the outer wall of the rotating shaft 2, and the support vertical board 1 The outer wall is fixedly installed with a driving motor 4 fixedly connected to one end of the rotating shaft 2, and two guide rollers 5 are fixedly connected between the opposite side walls of the two support vertical plates 1, and the opposite side walls of the two support vertical plates 1 are provided with Slideway 6, between two slideways 6, slide block 7 that fits with the outer wall of the upper end of reel 3 is slidably connected, and the side wall of slideway 6 is provided with sliding rheostat 9, and the side wall of slide block 7 is fixedly connected with sliding block 7. The rheostat slide 8 matched with the rheosta...

Embodiment 2

[0033] refer to Figure 1-2 , is basically the same as Embodiment 1, furthermore: the automatic cut-off mechanism includes a first piston 11 slidably connected in the energy storage box 10, the first piston 11 is fixedly connected with the slider 7 through a slide rod 12, and the energy storage The upper end of the box 10 and the cutting box 13 is communicated through a connecting pipe 16. The cutting box 13 is slidably connected with a second piston 14 with a blade 15 connected to the lower end. The middle part of the connecting pipe 16 is provided with an overflow valve 17. The upper end of the energy storage box 10 is provided with a first suction pipe 20, the first suction pipe 20 is provided with a first check valve 21, the lower end of the energy storage box 10 is provided with a second suction pipe 30, and the second suction pipe 30 is provided with a There is a second one-way valve 31 in the opposite direction to the first one-way valve 21. When the winding of the text...

Embodiment 3

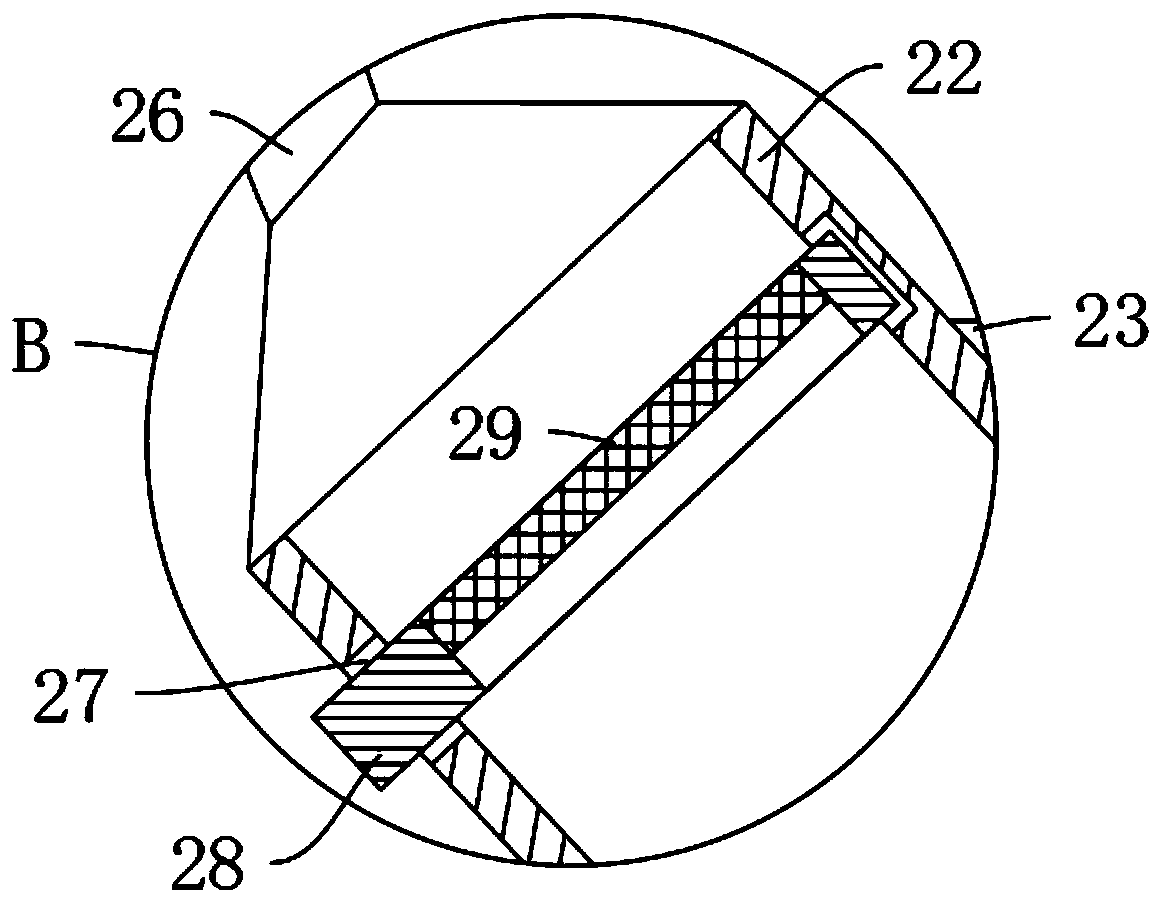

[0037] refer to figure 1 and image 3 , is basically the same as Embodiment 1, furthermore: the side wall of the slider 7 is fixedly connected with the dust collection cover 22 through the connecting plate 23, the opening of the dust collection cover 22 is inclined to the outer wall direction of the reel 3, and the energy storage box 10 The lower end side wall of the lower end side wall is fixedly connected with the third suction pipe 24, and the third check valve 25 opposite to the direction of the second check valve 31 is installed in the third suction pipe 24, and the dust suction cover 22 is connected with the third suction pipe. 24 are communicated with each other through telescopic hose 26, the material of telescopic hose 26 is rubber, and the inside of dust collection cover 22 is connected with filter screen 29, during the reel winding period, that is, during the sliding block 7 upwards, the third suction The trachea 24 sucks air through the telescopic hose 26 to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com