Long-chain saturated fatty glyceride nano-emulsion pore suppository and preparation method thereof

A fatty acid glyceride and nano-emulsion technology, applied in the field of concrete admixtures, can solve the problems of large lipophilic interaction, hidden health risks, easy agglomeration and delamination or gelation, etc., and achieves improved early strength, improved stability, and improved flow. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

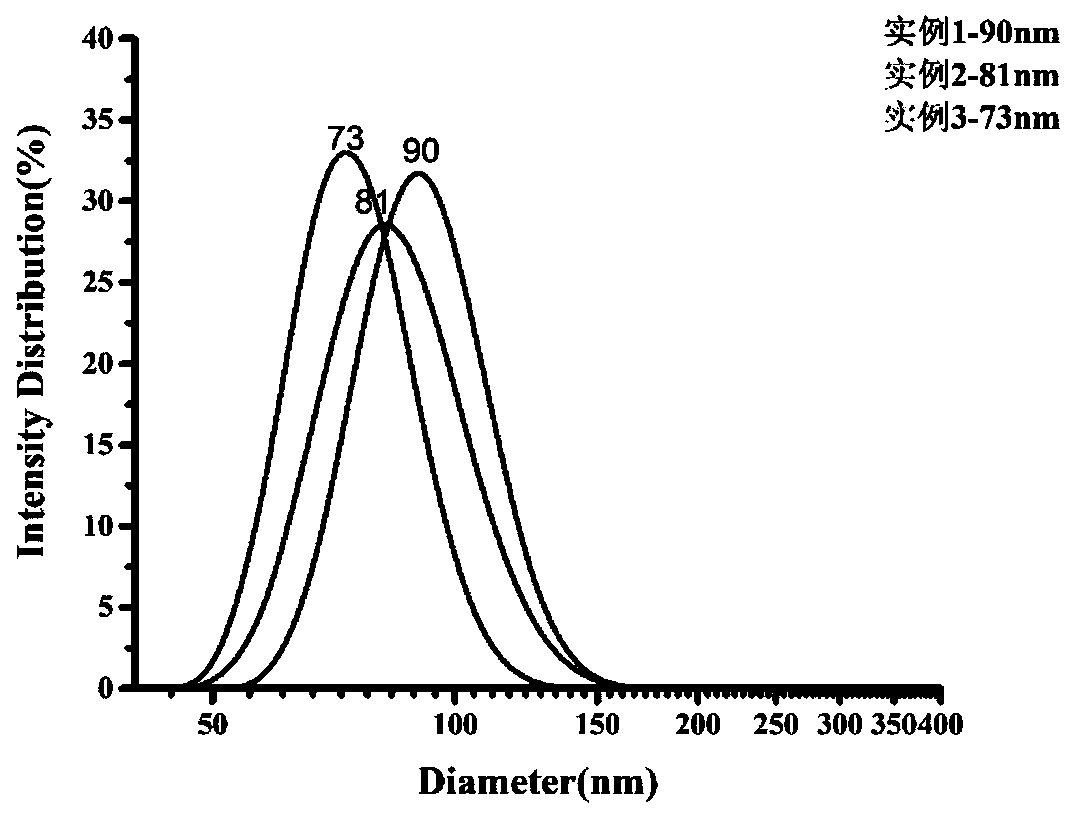

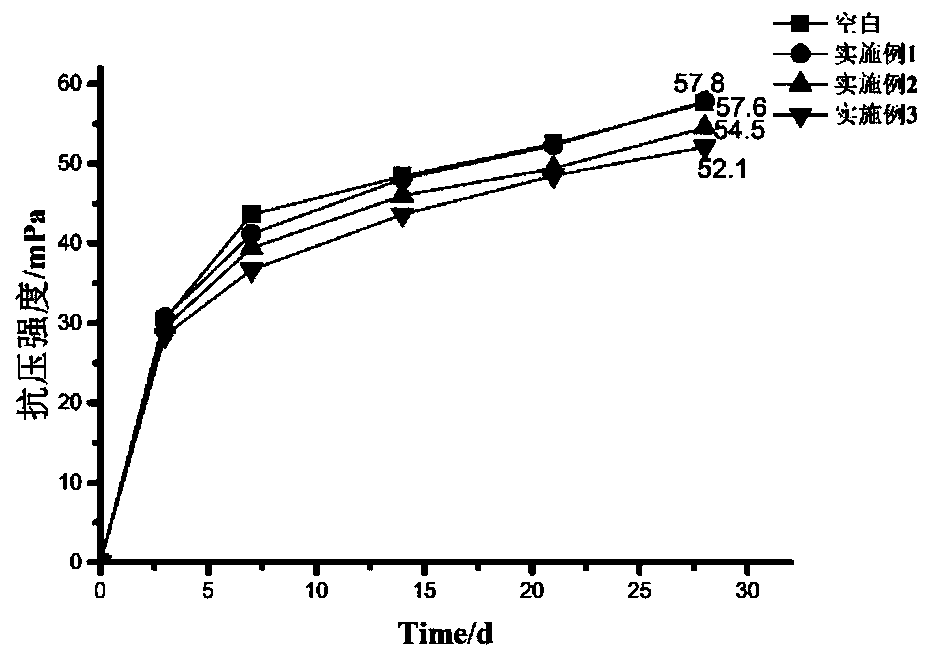

[0028] A long-chain saturated fatty acid glyceride nanoemulsion pore suppository, the raw materials of which are: 8.86wt% of hardened oil, 0.11wt% of defoamer, 2.03wt% of ammonia, 0.18wt% of triethanolamine, and the balance is deionized Water; the ammonia concentration is 10%.

[0029] The preparation method of the long-chain saturated fatty acid glyceride nanoemulsion pore suppository provided in this example, the specific steps are as follows: put 50 g of hardened oil in a three-necked flask and heat it to dissolve at 85° C. The heating time is 20 minutes. After dissolving, add 13 g Ammonia and 500g of water, then rapidly hydrolyzed and emulsified at 85°C at 1100r / min for 1h; then, add 1g of triethanolamine at 75°C, stirring at a rapid rate of 1100r / min for 1.5h; then, vacuum at 70°C Pump ammonia gas to a pH range of 7 to 7.5; then, add 0.6g of defoamer at 70°C, and stir at a slow speed for 0.5 to 1 hour to eliminate foam; finally, stir at a slow speed of 450r / min for 4 hour...

Embodiment 2

[0031] A long-chain saturated fatty acid glyceride nanoemulsion pore suppository, the raw materials of which are: 7.8wt% of hardened oil, 0.16wt% of antifoaming agent, 4.5wt% of ammonia water, 0.26wt% of triethanolamine, and the balance is water; The ammonia concentration is 10%.

[0032]The preparation method of the long-chain saturated fatty acid glyceride nanoemulsion pore suppository provided in this example, the specific steps are as follows: put 45g of hardened oil in a three-necked flask and heat it to 85°C to dissolve it for 20 minutes. After dissolving, add 26g Ammonia water and 500g water, then rapidly hydrolyzed and emulsified at 85°C at 1200r / min for 1 hour; then, add 1.5g of triethanolamine at 85°C, rapidly 1100r / min stirred, replaced and emulsified for 1.5h; then, vacuum at 70°C Pump ammonia gas to a pH range of 7 to 7.5; then, add 0.9g of defoamer at 70°C, stir at a slow speed for 0.5 to 1 hour to eliminate foam; finally, stir at a slow speed of 450r / min for 4 h...

Embodiment 3

[0034] A long-chain saturated fatty acid glyceride nanoemulsion pore suppository, the raw materials of which are: 7.03wt% of hardened oil, 0.21wt% of defoamer, 4.57wt% of ammonia, 0.35wt% of triethanolamine, and the balance is water; The ammonia concentration is 10%.

[0035] The preparation method of the long-chain saturated fatty acid glyceride nanoemulsion pore suppository provided in this example, the specific steps are as follows: put 40 g of hardened oil in a three-necked flask and heat to dissolve at a temperature of 85 ° C. The heating time is 20 minutes. After dissolving, add 26 g Ammonia and 500g of water, then rapidly hydrolyzed and emulsified at 85°C at 1300r / min for 1h; then, add 2g of triethanolamine at 85°C and stir at a medium speed of 1300r / min for 1.5h; then, vacuum pump at 70°C Ammonia gas to a pH range of 7 to 7.5; then, add 1.2g of defoamer at 70°C, and stir slowly for 0.5 to 1 hour to eliminate foam; finally, stir at a slow speed of 450r / min for 4 hours a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com