High-strength asphalt concrete and preparation method thereof

An asphalt concrete, high-strength technology, applied in the field of asphalt concrete, can solve the problems of low structural strength, road potholes and other problems, and achieve the effect of improving structural strength, good quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

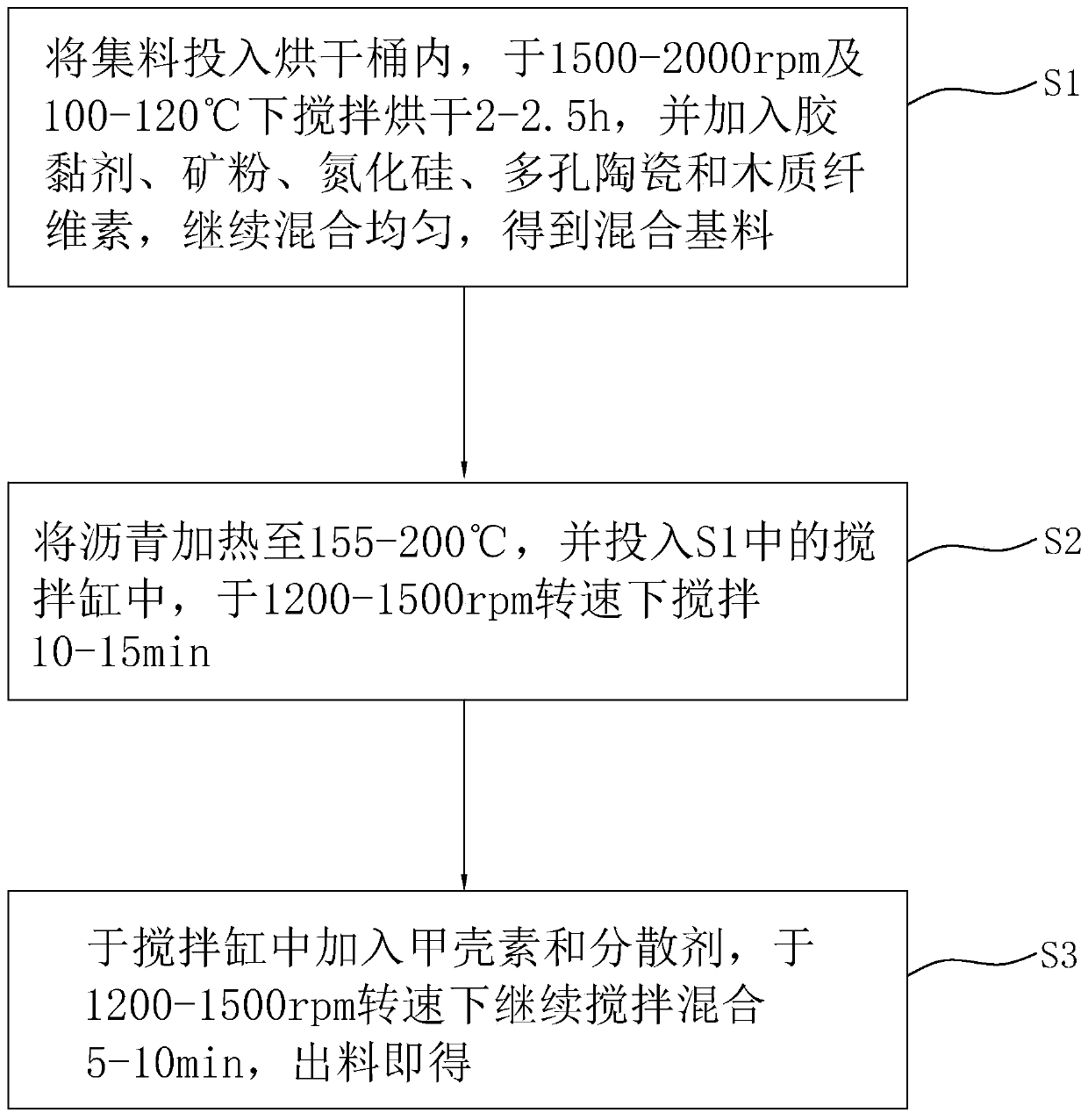

[0052] Embodiment 1: as figure 1 , a high-strength asphalt concrete, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0053] S1, put the aggregate into the drying barrel, stir and dry at 1500rpm and 100°C for 2.5h, add adhesive, mineral powder, silicon nitride, porous ceramics and lignocellulose, and continue to mix evenly to obtain a mixed base material;

[0054] S2, heat the asphalt to 155°C, put it into the mixing tank in S1, and stir at 1200rpm for 15min;

[0055] S3, add chitin and dispersant into the mixing tank of S2, continue to stir and mix at 1200rpm for 10min, and then discharge.

[0056] In this example, limestone aggregate was used as the aggregate; SBS modified asphalt was used as the asphalt; epoxy nitrile rubber was used as the adhesive; sodium lignosulfonate was used as the dispersant.

Embodiment 2-6

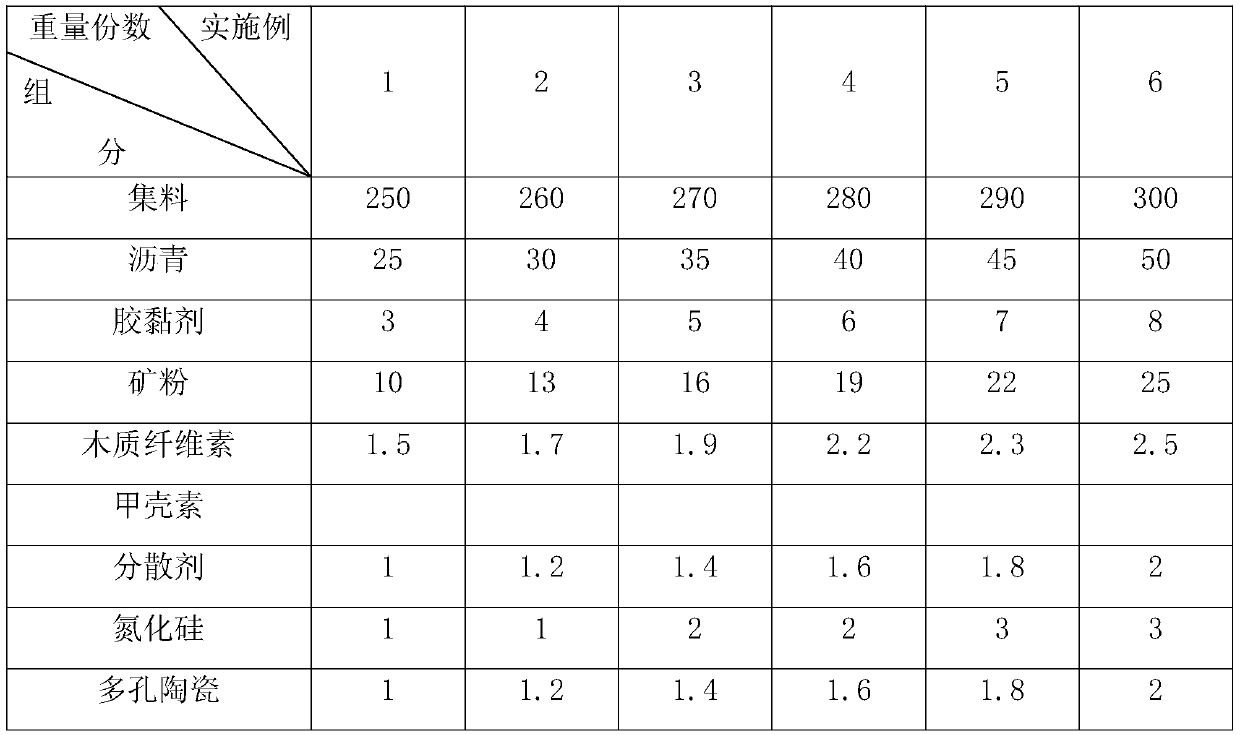

[0057] Example 2-6: a high-strength asphalt concrete, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0058] Each component and parts by weight thereof in table 1 embodiment 1-6

[0059]

Embodiment 7

[0060] Embodiment 7: a kind of high-strength asphalt concrete, the difference from embodiment 1 is that it is prepared through the following steps:

[0061] S1, put the aggregate into the drying barrel, stir and dry at 1700rpm and 110°C for 2.2h, add adhesive, mineral powder, silicon nitride, porous ceramics and lignocellulose, and continue to mix evenly to obtain a mixed base material;

[0062] S2, heat the asphalt to 175°C, put it into the mixing tank in S1, and stir at 1350rpm for 12min;

[0063] S3, add chitin and dispersant into the mixing tank of S2, continue to stir and mix at 1350rpm for 7 minutes, and the material is ready.

[0064] In this embodiment, basalt aggregate is used as the aggregate; neoprene rubber-modified asphalt is used as the asphalt; isoprene rubber is used as the adhesive; and polyethylene glycol is used as the dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com