Anti-sticking agent and preparation method thereof

A technology of anti-sticking agent and solvent, applied in textile and papermaking, fiber raw material processing, paper coating and other directions, can solve the problems of slow dissolution, easy volatility, high price, etc., to avoid resin powder, long-lasting anti-sticking effect, Good anti-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

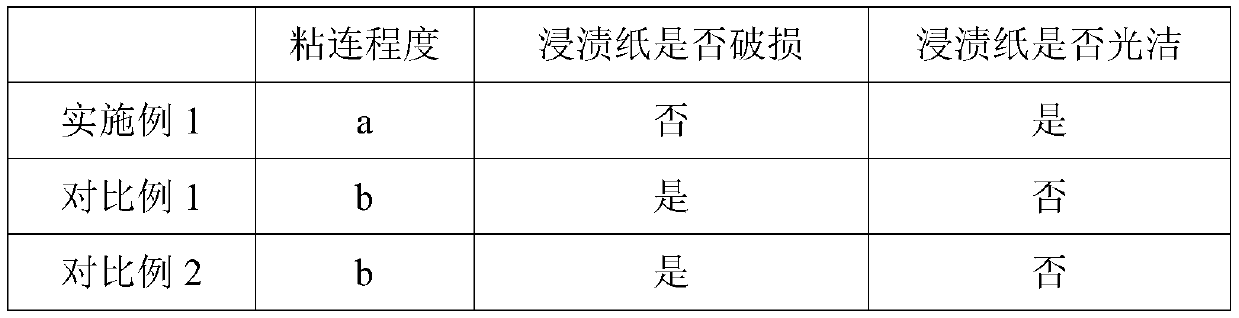

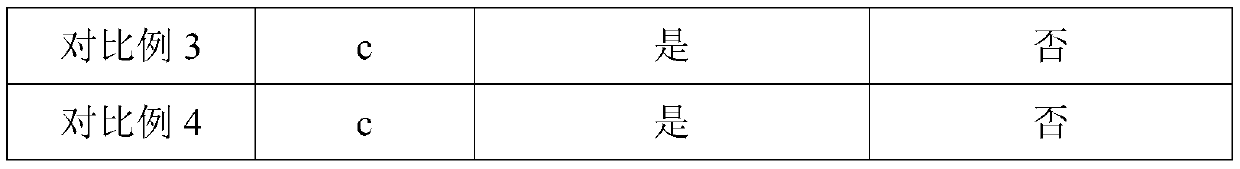

Examples

preparation example Construction

[0045] The second aspect of the present invention provides a preparation method according to the anti-adhesive agent, which is characterized in that it includes at least the following steps: adding each component into a reaction kettle and stirring evenly.

[0046]In a preferred embodiment, the preparation method of the anti-adhesive agent at least includes the following steps: first add the organic acid into the reaction kettle, then add the organic amine, heat to 90-120°C, and stir for 0.5h Finally, add the solvent, stir evenly, then add the dispersant and penetrant in turn, stir evenly, and the product is ready to use.

[0047] The third aspect of the present invention provides an application of the anti-adhesive agent in the anti-adhesion of the wood-based panel mesh belt and the anti-adhesion and dust removal of the impregnated paper.

Embodiment 1

[0051] Embodiment 1 of the present invention provides a kind of antisticking agent, by weight, preparation raw material is: 36 parts of organic acids, 6 parts of organic amines, 13 parts of dispersants, 25 parts of penetrating agents, 20 parts of solvents; The agent is a long carbon chain polyoxyl hydroxyl compound.

[0052] The organic acid is oleic acid.

[0053] The organic amine is N,N-dimethylethanolamine.

[0054] The dispersant is nonylphenol polyoxyethylene ether; the nonylphenol polyoxyethylene ether includes low hydroxyl value nonylphenol polyoxyethylene ether and high hydroxyl value nonylphenol polyoxyethylene ether; the low hydroxyl value The hydroxyl value of nonylphenol polyoxyethylene ether is 80 to 88 mgKOH / g; the hydroxyl value of the high hydroxyl value nonylphenol polyoxyethylene ether is 150 to 170 mgKOH / g; the low hydroxyl value nonylphenol polyoxyethylene The weight ratio of ether and high hydroxyl value nonylphenol polyoxyethylene ether is 1:1.3.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com