Screen lightening system

A screen and module technology, applied in image data processing, instruments, electrical components, etc., can solve the problem of low yield of OLED products, achieve the effects of stable structure, high lighting success rate, and convenient product replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

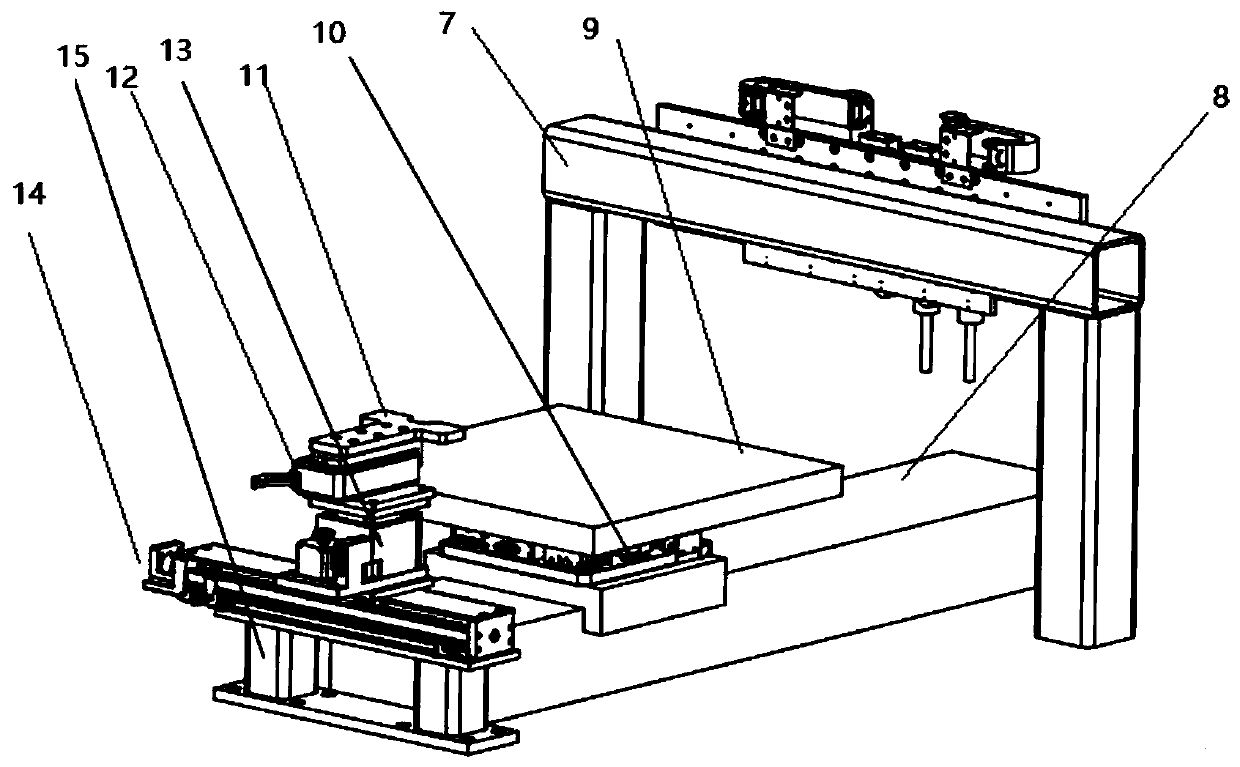

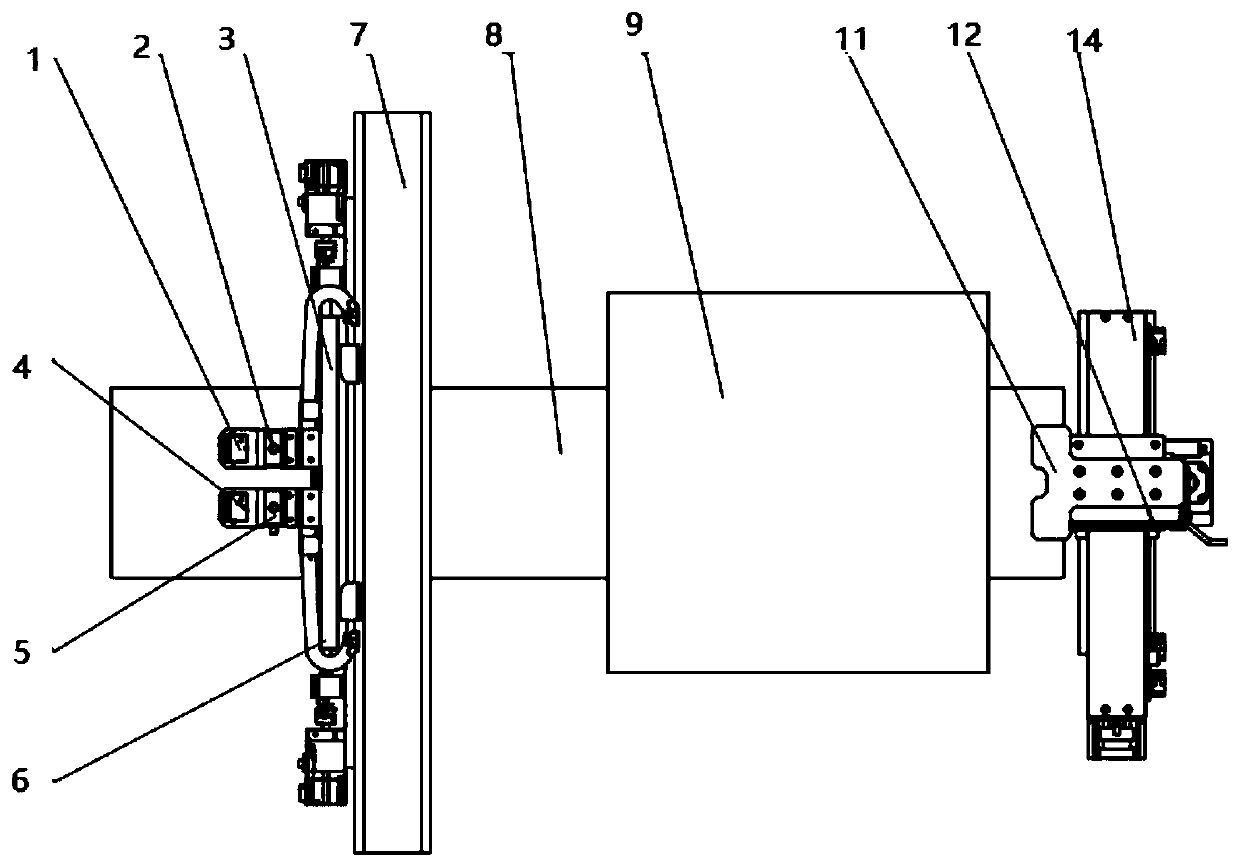

[0032] Such as Figure 1-2 As shown, in this embodiment, a screen lighting system includes a first camera assembly 1, a second camera assembly 4, a support frame 7, a linear motor transfer module 8, a suction cup 9, and the support frame 7 is vertically Arranged vertically, the first camera assembly 1 and the second camera assembly 4 are slid on the support frame body 7, and a linear motor transfer module 8 is arranged vertically below the support frame body 7, and the linear motor transfer module 8 slides A suction cup 9 for fixing the screen is provided, and a detection device for lighting the screen is provided at one end of the linear motor transfer module 8 .

[0033] The linear motor transfer module 8 includes a linear motor stator and a mover linear guide rail. The output end of the module is connected with the linear motor mover and the linear guide rail slider. The linear motor mover acts as a force output unit to push the output end of the module to slide. The Y-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com