Rapid and simple preparation method of mechanical expansion discoloration mechanism device

A simple and fast technology, applied in the fields of instruments, optical components, optics, etc., can solve the problems such as the report of the elastic film fast response full chromatographic color changing device, and achieve the effect of fast color changing response speed, simple preparation and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

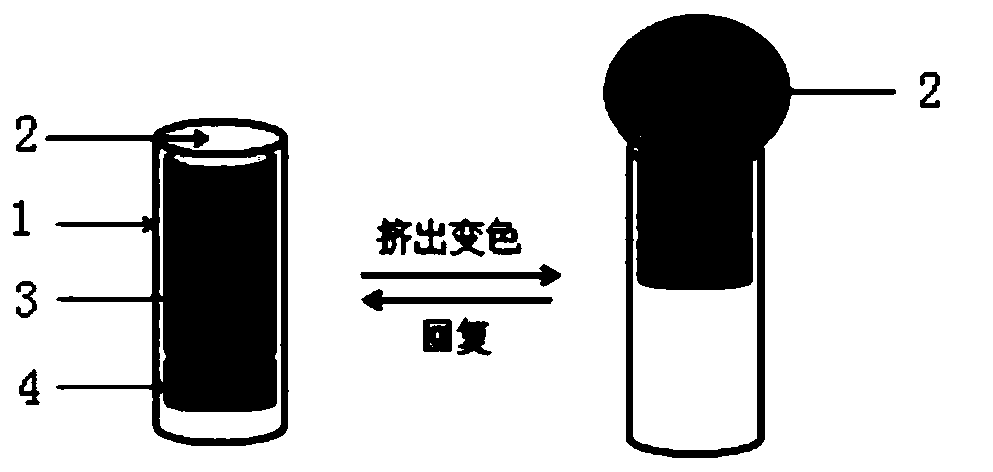

[0033] The preparation method of the double-layer elastic film of the present invention comprises the following steps:

[0034] (1) The polymer elastomer precursor is dissolved in an organic or inorganic solvent by a mechanical stirring / vibration method, wherein the mass percent concentration of the polymer in the mixed solution is 1% to 90%, forming an elastomer solution A, which is divided into two share;

[0035] (2) Disperse the inorganic pigment particles in a part of the solution A obtained in step (1) by mechanical stirring / vibration method, and form a homogeneous mixed solution B after mixing; wherein, the mass percent concentration of the inorganic dye particles is 1% to 70%. ;

[0036] (3) Pour a certain amount of solution A into the petri dish to cover the whole petri dish, put it in an oven and dry until half dry;

[0037] (4) Pour the mixed liquid B into the elastomer petri dish obtained in (3), and put it into an oven to dry until it is completely dry to obtain...

Embodiment 1

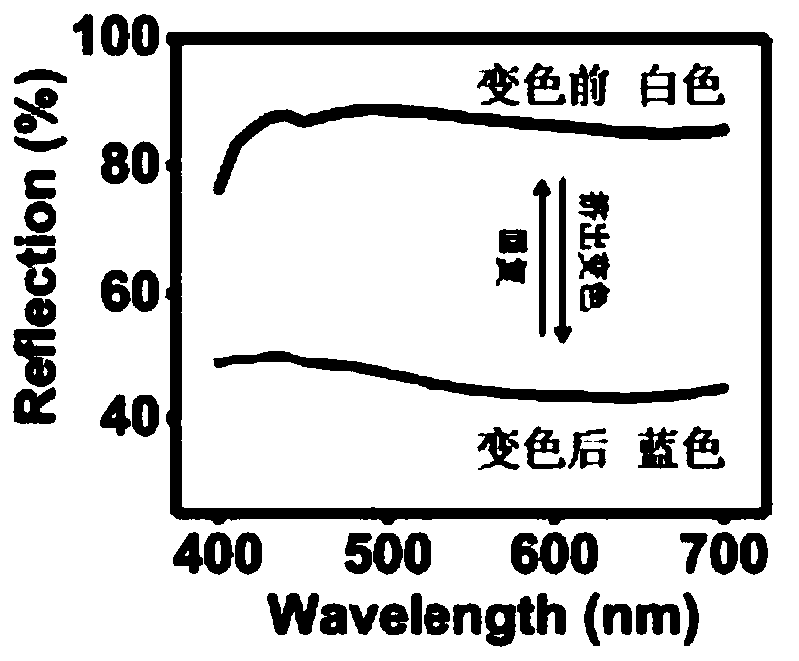

[0040] (1) Add 0.25g of titanium dioxide white powder and 5g of natural rubber stock solution in a beaker, form a uniform mixture A by mechanical stirring and ultrasonic vibration, wherein the stirring temperature is 30°C, the speed is 50 rpm, and the time is 1 Hour;

[0041] (2) Pour 5g of rubber stock solution into a petri dish with a diameter of 10cm to cover the entire petri dish, put it in an oven at 80°C and bake for 30 minutes until it is half dry;

[0042] (3) Pour 5 g of mixture A into the elastomer petri dish obtained in (2), put it in an oven at 80° C. and bake for 3 hours until it is completely dry to obtain a double-layer elastic film.

[0043] (4) Add 0.001 g of methylene blue dye to 10 g of aqueous solution in a beaker to obtain a blue filled aqueous solution.

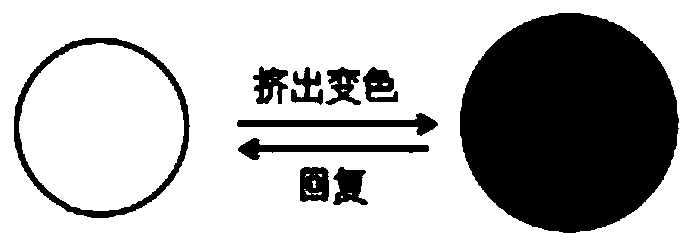

[0044] (5) Seal one end of a steel pipe with a diameter of 1 cm and a length of 15 cm with the prepared double-layer elastic film, with the layer containing titanium dioxide facing outward, and after fi...

Embodiment 2

[0046] (1) Add 2.5g Ecoflex A and 2.5g Ecoflex B into a beaker, and form a uniform polymer A by mechanical stirring method, which is divided into two parts, wherein the stirring temperature is 30°C, the speed is 50 rpm, and the time is 1 Hour;

[0047] (2) Add 0.25g of ferric oxide powder and 2.5g of polymer A in a beaker to form a homogeneous mixture B by means of mechanical stirring and ultrasonic vibration, wherein the stirring temperature is 30°C and the speed is 50 rpm, The time is 1 hour;

[0048] (3) Pour 2.5g of polymer A into a petri dish with a diameter of 10cm to cover the entire petri dish, put it in an oven at 80°C and bake for 30 minutes until it is half dry;

[0049] (4) Pour 2.5 g of mixture B into the elastomer petri dish obtained in (3), put it in an oven at 80° C. and bake for 3 hours until it is completely dry to obtain a double-layer elastic film.

[0050] (5) Add 0.001 g of methylene blue dye to 10 g of aqueous solution in a beaker to obtain a blue filled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com