Neodymium-iron-boron permanent magnet material, and raw material composition, preparation method and application thereof

A technology of raw material composition and permanent magnet materials, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of not being able to guarantee magnetic properties, anti-demagnetization properties and heat treatment temperature zones at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

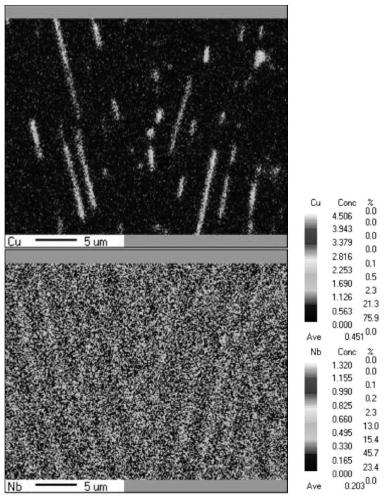

Image

Examples

preparation example Construction

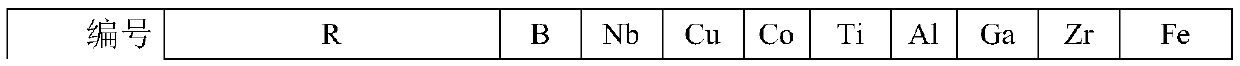

[0163] The preparation method of NdFeB permanent magnet material is as follows:

[0164] In the examples and comparative examples of the present invention, the introduced carbon impurity and oxygen impurity contents are conventional in the art.

[0165] (1) Melting and casting process: according to the formula in Table 1, put the prepared raw materials in Table 1 into an alumina crucible, and carry out vacuum melting in a high-frequency vacuum melting furnace with a vacuum of 0.05Pa and 1500°C . The argon gas is introduced into the high-frequency vacuum induction quick-setting belt furnace for casting, and then the alloy is quenched to obtain an alloy sheet with a thickness of 0.3 mm.

[0166] (2) Hydrogen crushing process: Vacuumize the hydrogen crushing furnace where the quenched alloy is placed at room temperature, and then pass hydrogen gas with a purity of 99.9% into the hydrogen crushing furnace to maintain the hydrogen pressure at 90kPa. After fully absorbing hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com