Preparation method of neodymium-iron-boron alloy sheet

An alloy flake, NdFeB technology, applied in inductor/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems of easy deviation from design components, poor product stability, poor repeatability, etc., to achieve product stability Good, less fine crystal content, good remanence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

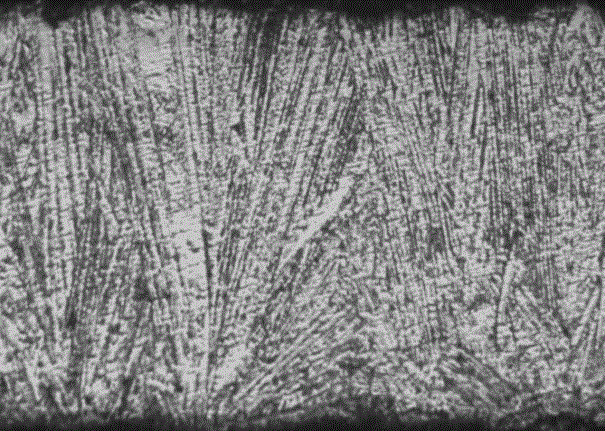

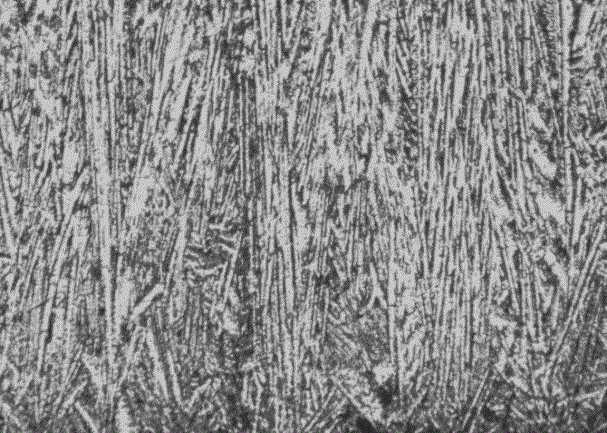

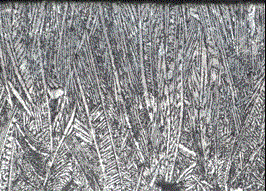

Image

Examples

Embodiment 1

[0036] (1) Charge: 380.65g (67.47wt%) pure iron, 0.91g (0.15wt%) zirconium, 3.61g (1wt%) cobalt, 30.08g (0.98wt%) boron iron, 0.60g (0.1wt%) ) Copper, 1.20g (0.20wt%) aluminum, 182.37g (30wt%) praseodymium neodymium alloy, 0.60g (0.1wt%) gallium raw materials are loaded into corundum crucibles from bottom to top, and fixed in a vacuum quick-setting furnace , close the furnace door;

[0037] (2) Vacuuming: Vacuumize the furnace to make the vacuum degree in the furnace reach 5Pa, and continue to heat and evacuate to 1Pa under the premise that the raw materials will not be heated to red;

[0038] (3) Argon filling: Fill the furnace with high-purity argon gas with a purity ≥ 99.99%, so that the pressure in the furnace reaches 50kPa and then stop argon filling;

[0039] (4) Melting: All the solid raw materials are melted into liquid state by induction heating, and the last piece of NdPr falls below the liquid level of the alloy through the observation window;

[0040] (5) Refinin...

Embodiment 2

[0048] (1) Charge: 380.65g (67.47wt%) pure iron, 0.91g (0.15wt%) zirconium, 3.61g (1wt%) cobalt, 30.08g (0.98wt%) boron iron, 0.60g (0.1wt%) ) copper, 1.20g (0.20wt%) aluminum, 182.37g (30wt%) praseodymium neodymium alloy, 0.60g (0.1wt%) gallium raw materials are loaded into corundum crucibles from bottom to top, and the crucibles are fixed in the vacuum quick-setting furnace. close the furnace door;

[0049] (2) Vacuuming: Vacuumize the furnace to make the vacuum degree in the furnace reach 5.5Pa, then heat and continue to evacuate to 1.5Pa under the premise that the raw materials will not be heated to red;

[0050] (3) Argon filling: Fill the furnace with high-purity argon gas with a purity ≥ 99.99%, so that the pressure in the furnace reaches 50kPa and then stop argon filling;

[0051] (4) Melting: All the solid raw materials are melted into a liquid state through induction heating, and the last piece of NdPr falls below the liquid level of the alloy through the observatio...

Embodiment 3

[0060] (1) Charge: 380.65g (67.47wt%) pure iron, 0.91g (0.15wt%) zirconium, 3.61g (1wt%) cobalt, 30.08g (0.98wt%) boron iron, 0.60g (0.1wt%) ) copper, 1.20g (0.20wt%) aluminum, 182.37g (30wt%) praseodymium neodymium alloy, 0.60g (0.1wt%) gallium raw materials are loaded into corundum crucibles from bottom to top, and the crucibles are fixed in the vacuum quick-setting furnace. close the furnace door;

[0061] (2) Vacuuming: Vacuumize the furnace to make the vacuum degree in the furnace reach 6Pa, and continue to heat and evacuate to 2Pa under the premise that the raw materials will not be heated to red;

[0062] (3) Argon filling: Fill the furnace with high-purity argon gas with a purity ≥ 99.99%, so that the pressure in the furnace reaches 50kPa and then stop argon filling;

[0063] (4) Melting: All the solid raw materials are melted into a liquid state through induction heating, and the last piece of NdPr falls below the liquid level of the alloy through the observation win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com