Production process of flaky abalone feed

A production process and feed technology, applied in the direction of feed, animal feed, dry solid materials, etc., can solve the problems of easy breakage, feed quality decline, etc., to achieve the effect of increasing temperature and avoiding quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0049] The production process of a kind of flaky abalone feed disclosed by the present invention comprises the following specific steps:

[0050] S1, feeding, sending each raw material into each silo;

[0051] S2, batching, sending the raw materials out from the silo and proportioning;

[0052] S3, mixing, mixing the raw materials that have been proportioned by a mixer;

[0053] S4, puffing, puffing the mixed raw materials through the puffing machine 1 and cutting them into pieces;

[0054] S5, drying, the cut feed is passed through the dryer 2;

[0055] S6, screening, the cut feed is screened by a screening machine;

[0056] S6, cooling, the dried feed is cooled by air cooling;

[0057] S7, packaging, packaging the cooled feed.

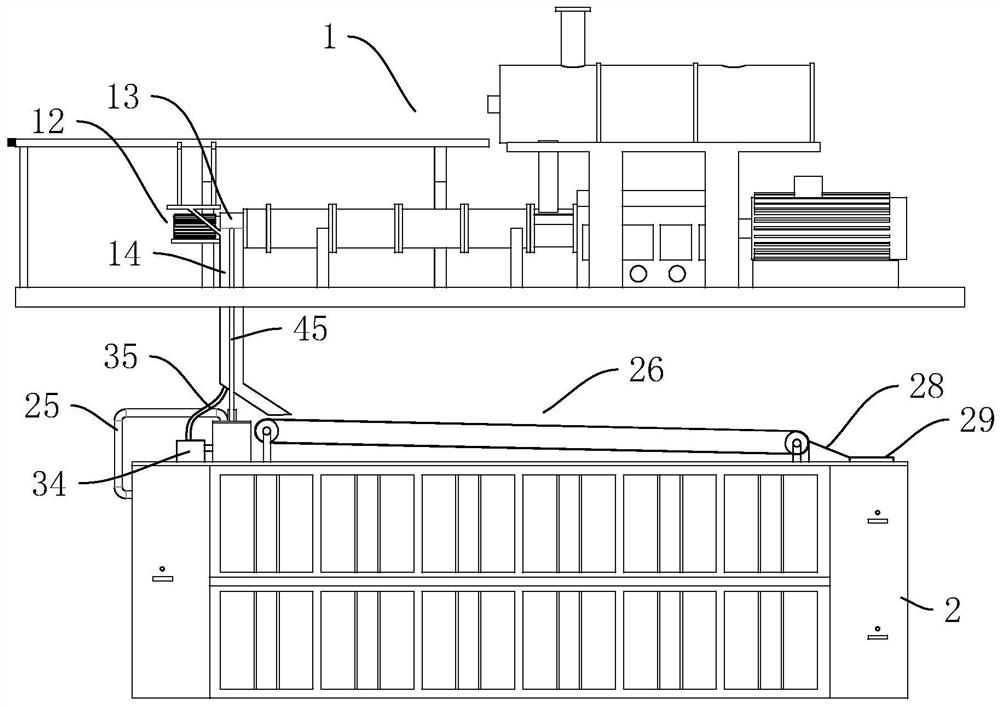

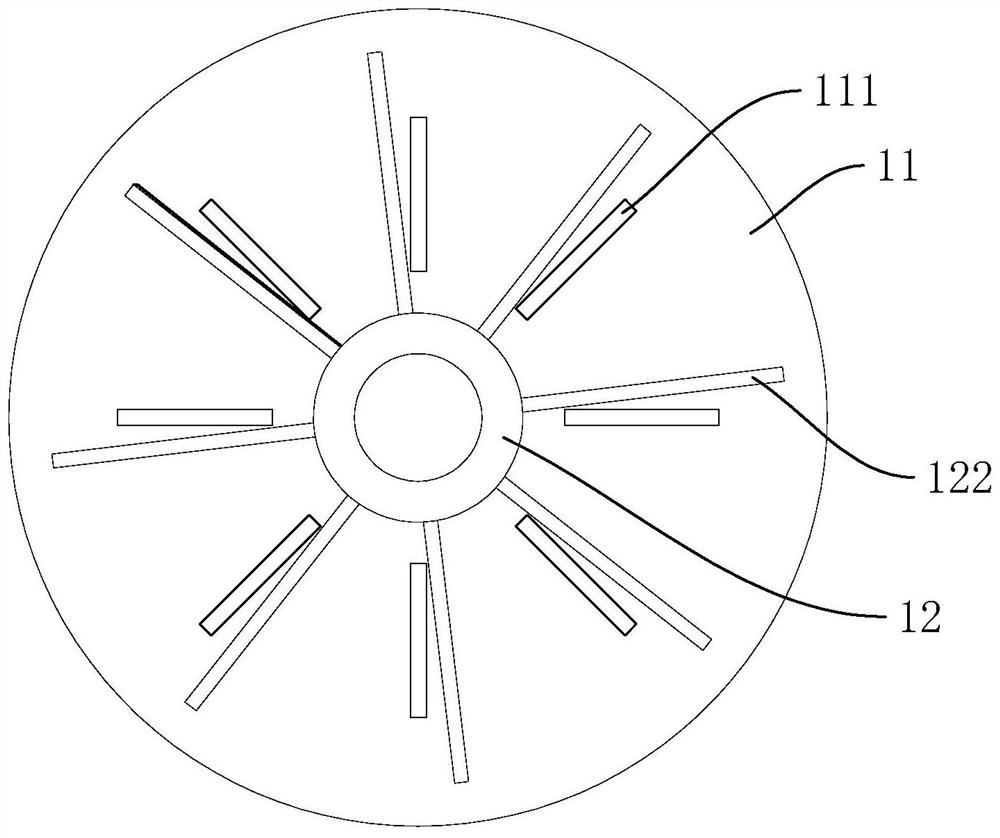

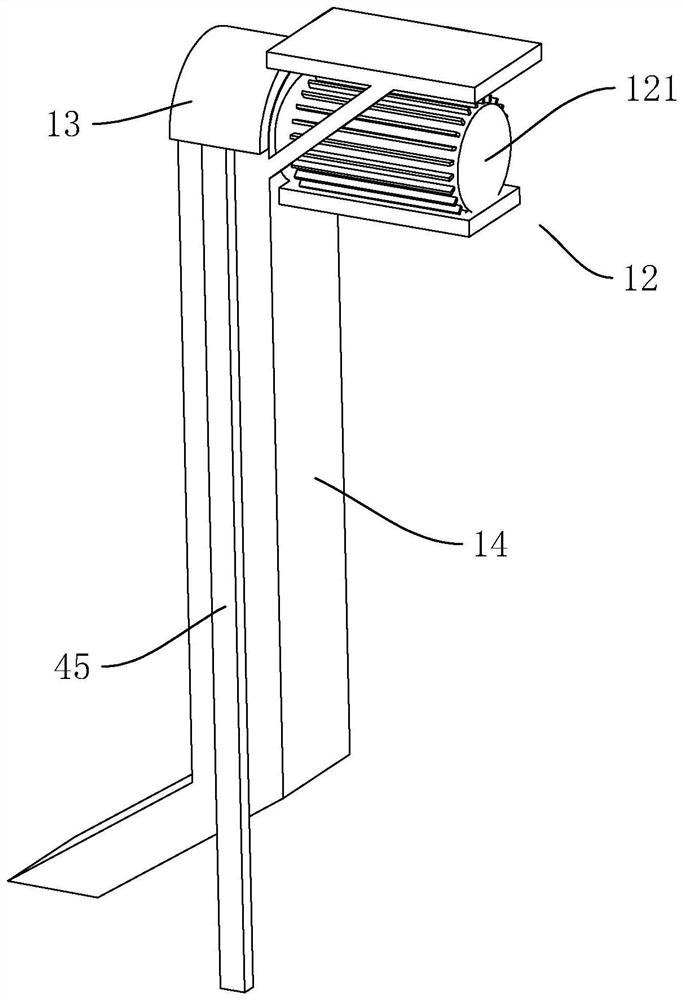

[0058] refer to figure 1 with figure 2 , wherein the puffing machine 1 is arranged on the floor above the dryer 2, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com